VERTICAL WIRE DRAWING (RIBBED) REBAR MACHINE

DEFORMED (RIBBED) WIRE MACHINE

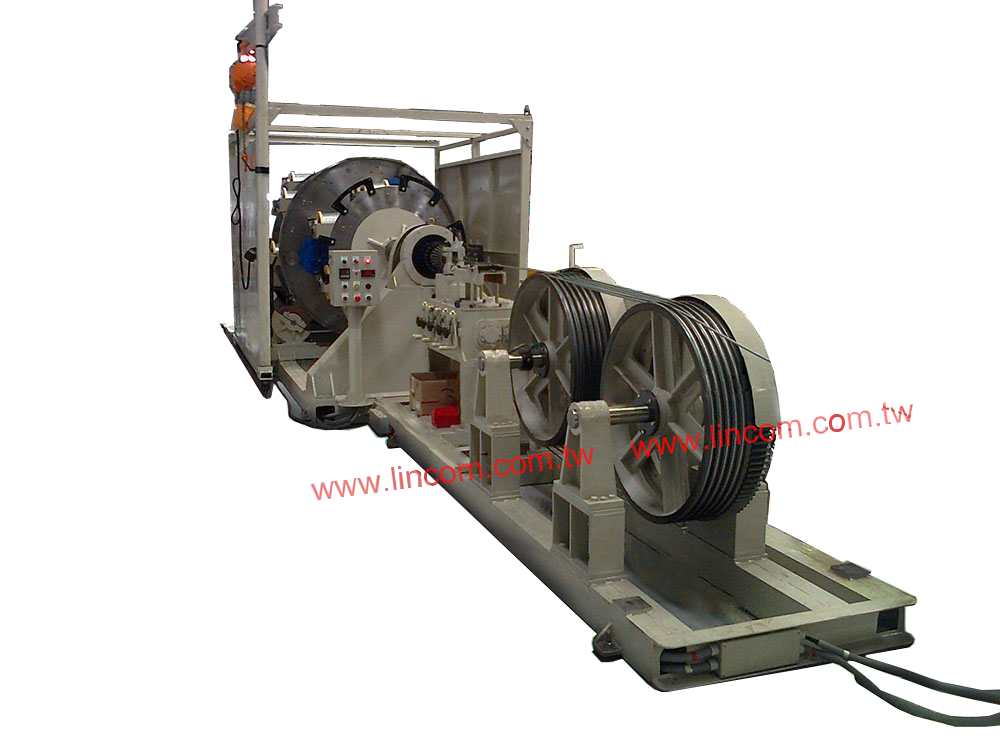

Vertical Deformed (Rebar) Wire Drawing Machine

* This vertical type single drum wire drawing machine is special designed to draw wire rod with descaler function.

The design saves the acid washing process, and hence lowering cost and waste issue.

* This machine adapts 2 sets of pattern rollers for wire drawing & profiling. End products is coiled on wire stand under the machine to unload.

* Contents: Vertical (Gravitity Block) Wire Drawing & Deformed (Ribbing) Machine, Profiling Machine, Wire Descaling Machine, Lubricant Power Case & Base, Profiling Machine Base, Wire Coil Stand, Wire Pointing Machine, Butt Welder.

| AC Motor | 100 hp |

| Inverter | 100 hp |

| Inlet Wire Dia. | 13 - 5.5 mm |

| Finished Wire Dia. | 12 - 4.0 mm |

| Wire Speed | 0 - 135 M/min |

| Coil Tension Releasing Device | AC 2hp x1 pc |

| Parts | a. Flat Rollers 1 set | |

| b. Kair Rollers 1 set | ||

| c. Wire Drum Bearing 1 set (3 pieces) | ||

| d. Bearing (Cooling & Lubrication) 1 set (3 pieces) | ||

Wire Descaling Machine / Wire Pointing Machine / Butt Welder

※Remark: For details please contact us.

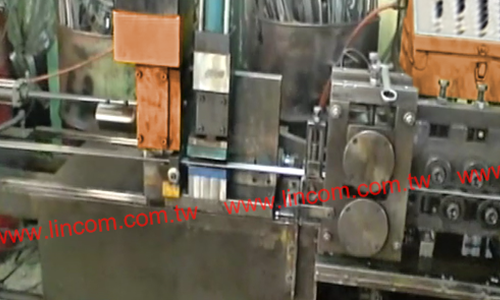

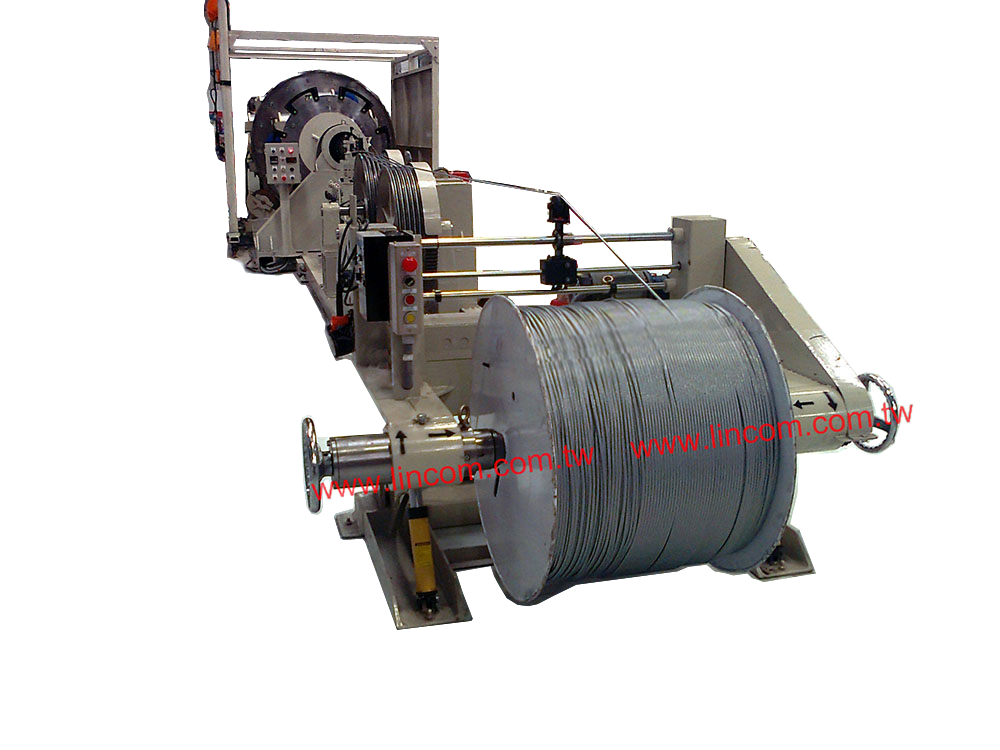

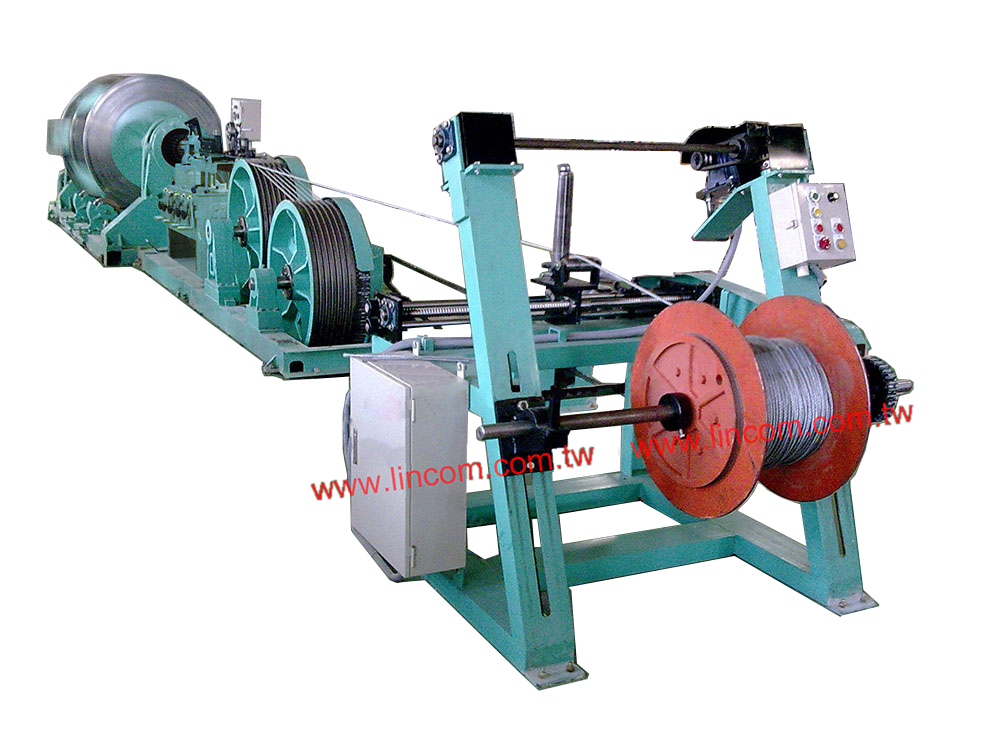

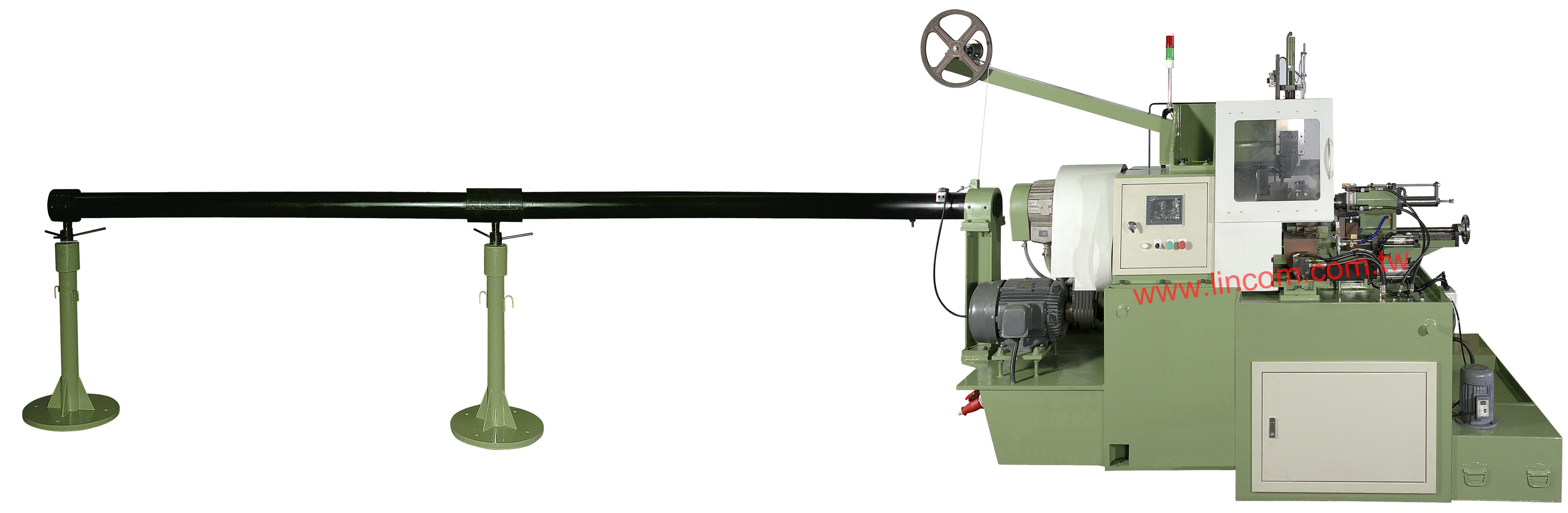

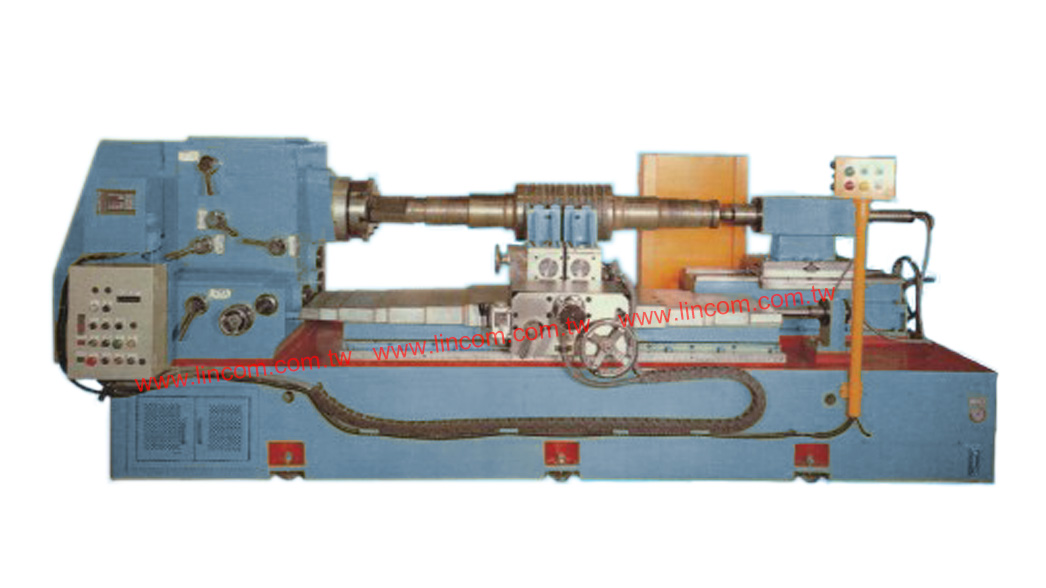

Horizontal Wire Deformed (Rebar) Drawing Machine

- Surface Hardness Treatment with Tungsten Carbide Alloy for Wire Drum

- Water Cooling System for Die Box

- Shutdown Device is available after End Wire Pass the Die

- Emergency Stop can be made upon wire breaking

- Brake Resistor

- Press Roller 2 sets

-drawing-machine/high-speed-deformed-wire-machine.jpg)

-drawing-machine/deformed-wire-drawing-machine.jpg)

-drawing-machine/horizontal-type-deformed-wire-machine.jpg)

-drawing-machine/rebar-product-01.jpg)

-drawing-machine/rebar-wire-deformed-drawing-machine.jpg)

-drawing-machine/wire-coil-and-mesh-panel.jpg)

-drawing-machine/horizontal-deformed-wire-machine.jpg)

-drawing-machine/rebar-product-02.jpg)

| Material | Low Carbon Steel |

| AC Motor | 125 HP |

| Inverter | 125 HP |

| Inlet Wire Dia. | 13mm-5mm (Low Carbon Steel Wire) |

| Finished Wire Dia. | 12mm-4mm |

| Wire Speed |

0-420M/minute 12mm-10mm 280M/minute 10mm-4mm 420M/minute |

* Inlet Wire Dia.: 5.0mm-12.0mm

* Wire Drawing Speed : 420M/minute (Max.)

* Equipped with

- Wire Passing Stand : 1 pc

- Oil Pressure type rotary wire supply coiler: 2 pcs

- Oil Pressure 7-1/2HP

- Wire Passing Wheel can move up and down, uplifting Max. 5000mm

(total height of device: 6000mm)

- Wire Twisting Sensing Device (with air cylinder device)

* Control:

- Wire Twisting Stop

- Wire Passing Wheel Can Move and set to ON/OFF

- With Maintaining ladder and Plateform

| 1 | Flat Rollers |

| 2 | Kair Rollers |

| 3 | Holder |

Descaling Machine / Butt Welder / Rotary Type Upper Feeding For Wire Supply / Take Up Machine

※Remark: For details please contact us.

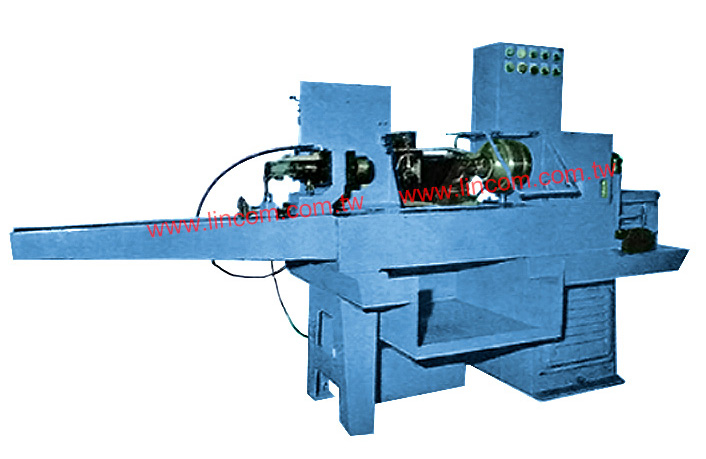

BIG DIA. WIRE DRAWING MACHINES

For Big Dia. Drawing Machine currently our largest diameter make is up to 50mm. Which is widely used in heavy industry: bolts, angle bolt, tower, vessel, and lighting pole fields, etc.

* Inlet Wire Dia.: 50 - 42, Output Wire Dia.: 48.5 - 38.5 mm

* Wire Speed: 0-25 M/min

* Drum: 1250 mm

* Wire Coil Frame: 2.5 tons

* 2 Units of Roller & 2 Units of Chuck

* With Counter, Speed Meter & Electric Control Device.

* Wire Drum with tungsten carbide alloy hardness treatment.

* Water cooling system for die box & drum.

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

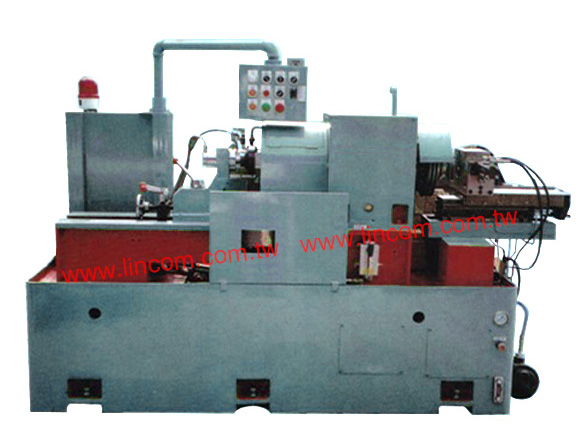

For Big Dia. Wire Straightening & Cutting Machine, the largest wire dia. we have made is up to 45mm. It is widely used in Linear Slide Rail, Stainless Steel Wire, Wind Power Plant, Vessel, Lighting Pole fields, etc.

* Motor: 20 hp/ Inverter: 20 hp

* Hydraulic Type Payoff Device 7-1/2 hp

* Horizontal Straightening Roller 2*3 (Reducer)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

WIRE STRAIGHTENING & CUTTING MACHINE

This machine is composed of Straightening Roller Sets & Set-Length Cutting two sectors. Steel Wire (Rod) is guided by feeding roller, after Straightening Roller Sets' straightening, steel wire passes through outlet feeding roller & enters the guiding pipe for Set-Length Cutting. The set- length cutting sector utlizes the mechanism of threads stripper and cutting arm.

When steel wire enters straightening rollers from inlet feeding roller which activates the rollers to spin, there is a counter on the straightening roller, the counter counts the length and sets the required length, so when cutting it spurs the threads stripper and the end product falls into the runout rack.

| Model | Wire Dia. | Length | Speed | Motor |

| RB -S9 | 5 - 9 mm | 1 - 12 M | 80 M/min | 30 HP/ 5 HP/ 5 HP |

| RB -S12 | 8 - 12 mm | 1 - 12 M | 120 M/min | 40 HP/ 15 HP/ 7.5 HP |

| RB -S20 | 12-16 mm | 1 - 12 M | 80, 56, 38, 24 M/min | 50 HP/ 20 HP |

| RB -S25 | 16 - 25 mm | 1 - 12 M | 23 M/min | 50 HP/ 10 HP/ 25 HP |

| RB -S30 | 20 - 30 mm | 1 - 12 M | 15 M/min | 60 HP/ 15 HP/ 40 HP 1 HP (7X) |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

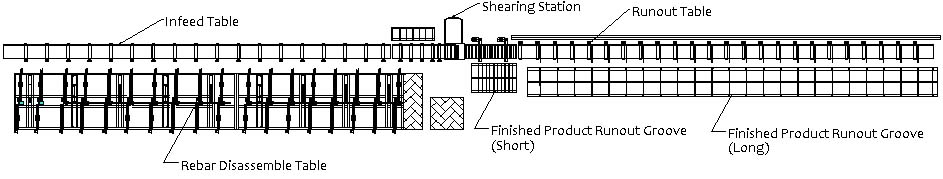

* Infeed Table: 18M

* Runout Table: 18M

* Shearing Force: 300 tons

* Cutting Knife: 600 mm

* Main Motor: 50 HP

* PLC Control

| HL-3210 Shearing Capacity Table (Number of Shearing Pieces Per Time) | ||||||||||

| Rebar Size (mm) | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 35 | 38 | 45 |

| Material SD280 | 50 | 45 | 34 | 30 | 27 | 22 | 12 | 6 | 3 | 1 |

| Material SD420 | 50 | 45 | 34 | 30 | 27 | 22 | 10 | 6 | 3 | 1 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

For metal joint by friction welding method, joint materials can be achieved within a short period of time. The welding no need extra heat nor welding rod, & no electric arc, spark, smog or toxicant is generated during process. After welding, the metallic properties of original material remains mainly the same, strength of the welded part is greater than originals. Suitable use in construction fields for Rebar & Coupler Friction Welding... other friction welding machine for different purposes

※Remark: For details please contact us.

Auto Rebar Head Forging Machine

| Model | Dia. Range | Length Range | Speed | Motor |

| RFG- 25 | 12 - 25 mm | 2 - 12 M | 140 pcs/hr | 15 hp |

| RFG- 50 | 25 - 50 mm | 2 - 12 M | 120 pcs/hr | 20 hp |

Auto Rebar Thread Cutting Machine

| Model | Dia. Range | Length Range | Speed | Motor |

| RTCT- 25 | 12 - 32 mm | 2 - 12 M | 120 pcs/hr | 3 hp |

| RTCT- 50 | 32 - 50 mm | 2 - 12 M | 90 pcs/hr | 5 hp |

Auto Rebar Saw Blade Cutting Machine

| Model | Dia. Range | Length Range | Speed | Motor |

| RSCT - 40 | 16 - 40 mm | 2 - 12 M | 200 pcs/hr | 3 hp |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

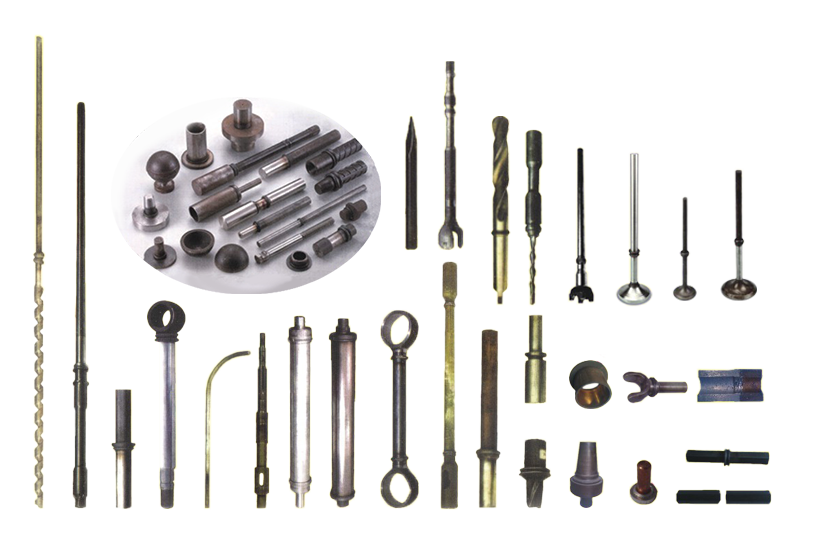

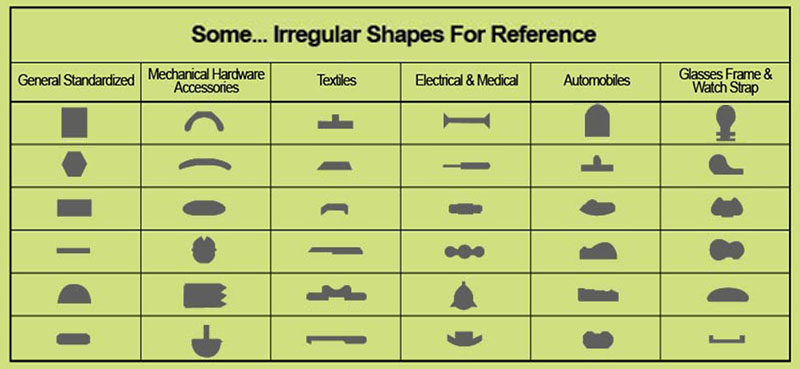

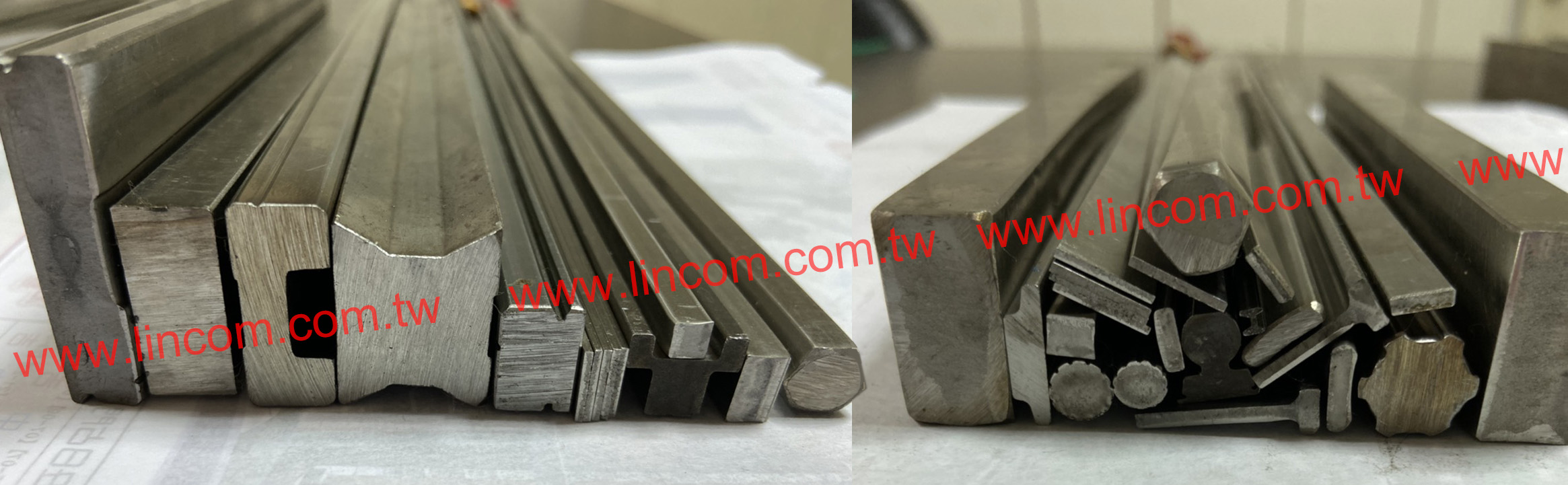

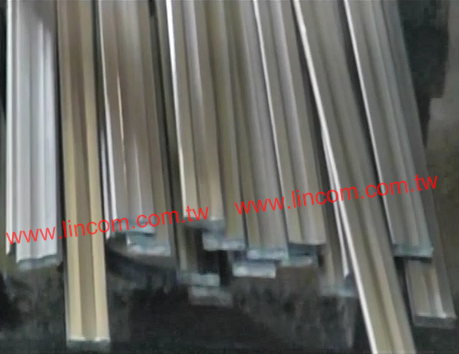

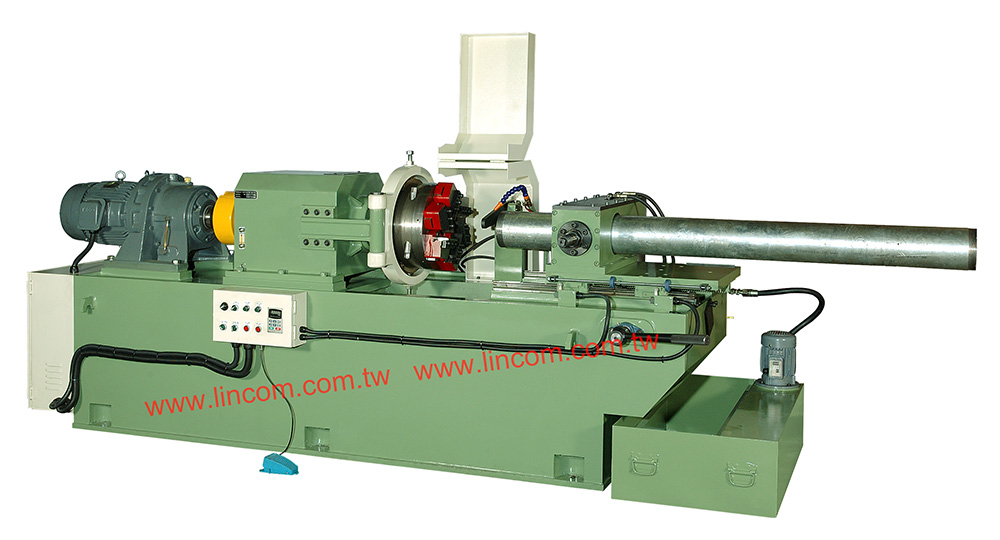

METAL BAR PEELING & IRREGULAR PROFILING MACHINE

Our Metal Shaped Profile Machine is designed for markets that in their actual industrial application requires higher-precision, lighter, smaller, and more delicate irregular shaped steel bars. As by traditional ways after cutting raw material.. then requires multiple processing to required shape...

So by our continuous metal bar shape profiling, customers' cost down, time saving, labor saving, and material saving can be easily achieved. Moreover, finished products is higher in precision, and with a smoother, brighter, and cleaner surface of metal materials.

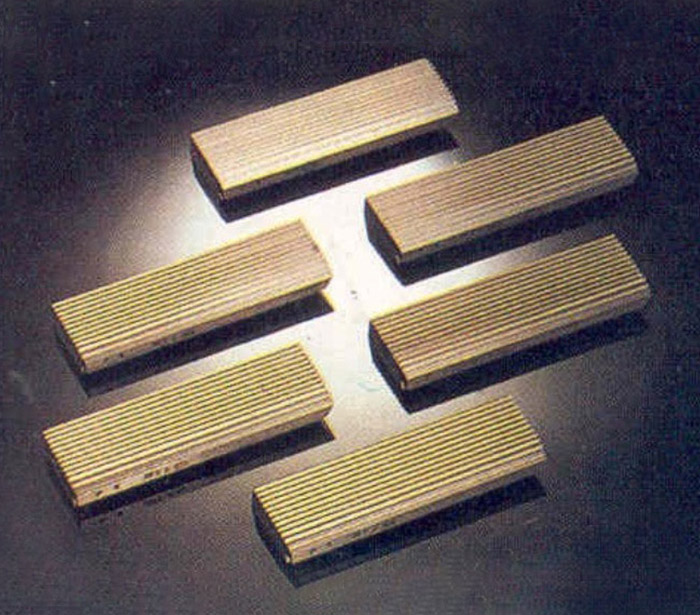

* For spring, lock and other mechanical hardware use

* Parts for Knitting Machine in Textile Industry

* Linear Guide Rail, Guild Block

* For Medical Instrument and Surgical Implant use

* For Electronic and Information Appliance use

* For Automobile Component & Piston Ring use

* Generally Applied Standardized Product (Common Shape /Profile: Square, Hexagon, Rectangle...)

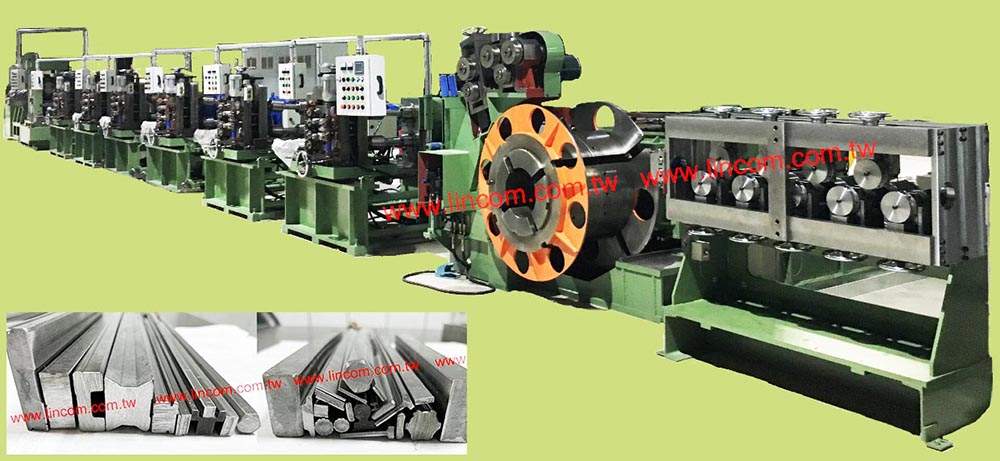

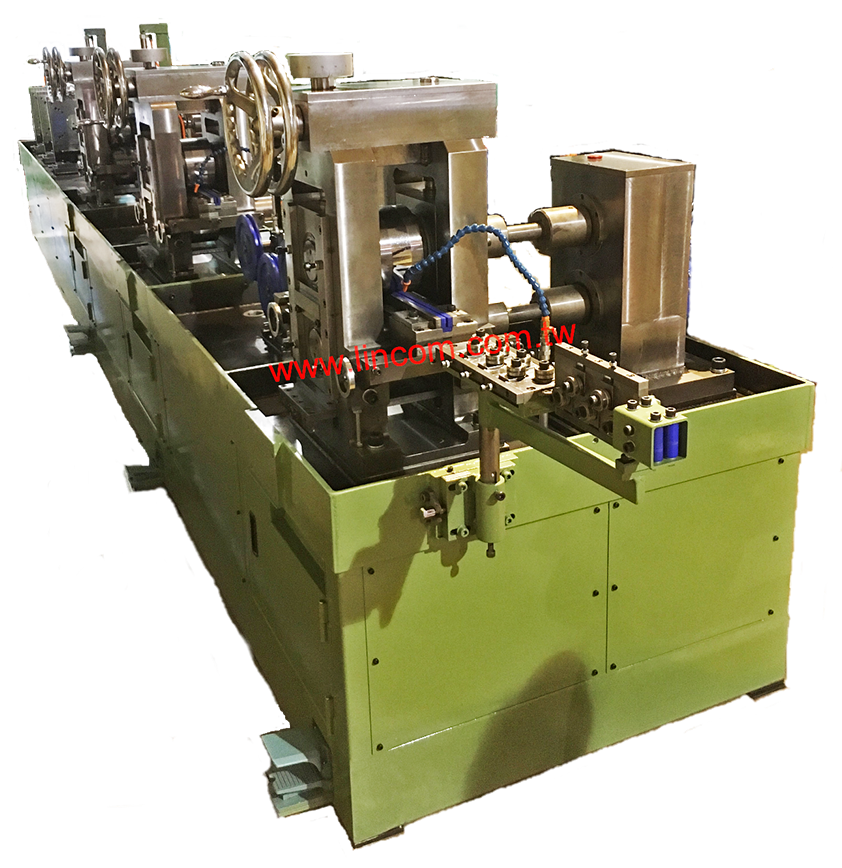

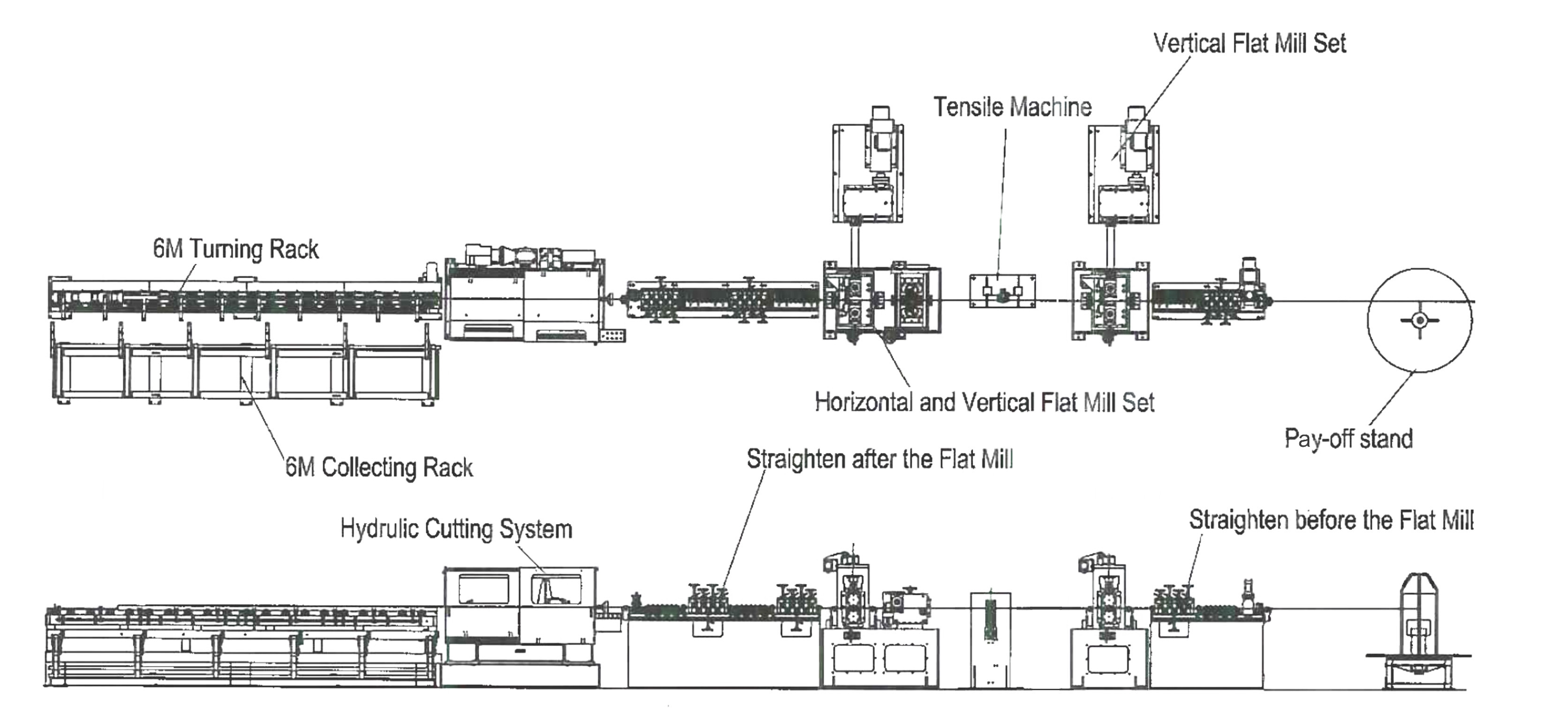

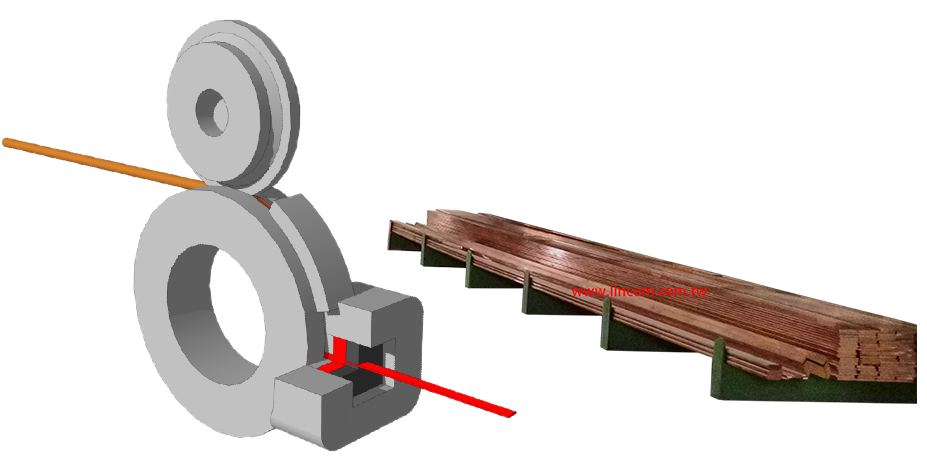

Continuous Metal Bar Irregular Shape Profiling Machine

Ø600~Ø180 Continuous Calender, Take Up, Cutting, Production Line

Contents:Uncoiler x1 set, Front End Straightening Machine x1 set, Ø600 Calender Machine x1 set, Ø180 Calender Machine x3-6 sets, Take Up Machine, Back End Straightening Machine x1 set, Cutting Machine, Stacking Conveyor.

This machine is for medium-large wire rod.

Capacity: 25M/min

Wire Rod Material: Iron, Steel, Copper, Stainless Steel Max. Ø 25 mm

Max. Take Up Loading Capacity: 1000 kg

Our standard cutting length is 1~6M, we accept customer's other cutting length requirement.

The number of Ø180 Calender Machine in line, can base on customer's requirement to either increase or decrease.

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

Wire Rod Material: Iron Max. Ø6 mm, Steel, Stainless Steel Max. Ø5 mm

Capacity: Our standard is 70M/n. We can customize production speed upon customer's demand, Stainless Steel can reach 150M/min.

※Customers specific requirement are Welcome!

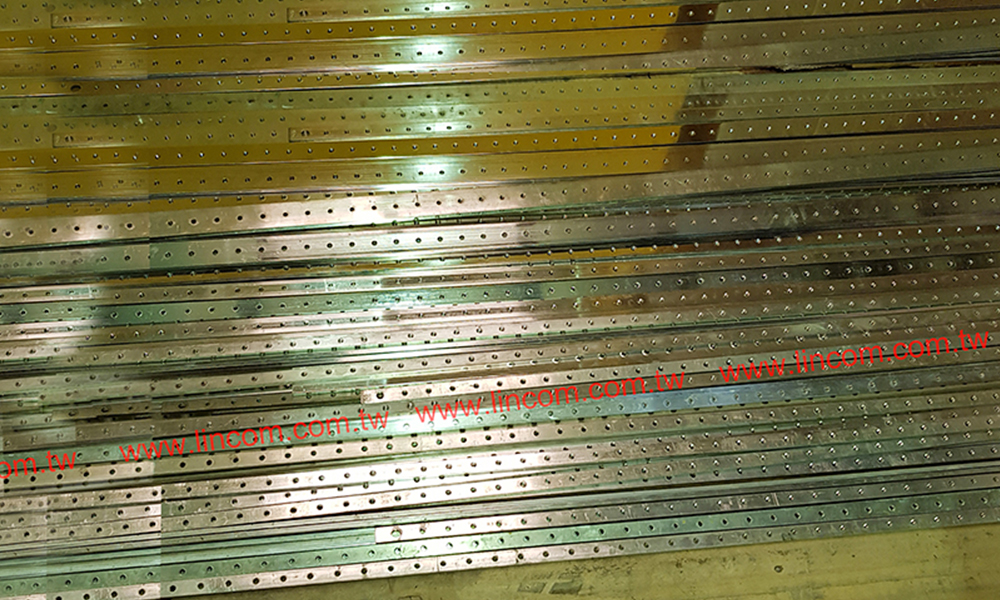

* Raw Material: Round Wire Dia.16 mm (As Per Flat Bar Size)

* Output : Dia. 12 x 3, 15 x 3, 20 x 4, 20 x 5 mm * Length: 2 - 6 M

* Width & Thickness Tolerance: +/- 0.5 mm * Max. Speed: 80M/min

ContentsPay-Off Stand (With Safety Limit Switch) / Striaghtening Roller / Vertical Flat Bar Milling Roller / Horizontal Flat Bar Milling Roller / Flat Bar Tension Adjust Device / Cutting Device / Turning Rack / Run Out Collecting Stand / Control Box / Cooling Device

※Customers specific requirement are Welcome!

COPPER & ALUMINUM BUS BAR EXTRUSION & DRAWING MACHINES

This continuous casting system is to produce bright & long oxygen-free copper rod.

* Rod Dia. Range: 8 - 20 mm

* Casting Strands: 12

* Speed of Draw Up: 0 - 2200 (mm/min)

* Speed of Melting Copper: 750 kg/h

* Melting Copper Consumption Rate : 320 kwh/ton

* Type of Taking-Up: Curvature Auto-Adjustment

* Induction Melting Furnace: Triple Furnaces Combined

ContentsInduction Melting Furnace / Continuous Casting Machine /

Frame of Guide Pulley / Caging Device / Double Head Recoiler Machine /

Cooling-Water System (Provided By Buyer) / Electric System /

Charging System / Temperature Control System.

※Remark: For details please contact us.

By continuously feeding raw material rod into a rotating wheel with groove. The rod is rubbed and extruded in the groove, generating sufficient temperature by enormous force of friction and extrusion, then getting to the state of recrystallization to be extruded and formed in one time through cavity and our designed die, which could promptly produce various copper and aluminum profiles.

* Extrusion Shape: Bus Bar, Round Bar, Square Bar, Hexagonal Bar, Octagonal Bar.

* Feeding Stock: OFC rod, dia. 12.5 & 16 mm

* Max. Production Size: Bus Bar is 132 x 20 mm & Solid Bar is dia. 40 mm

* Max. Width: Bar is 100 mm & Rod is dia. 40 mm

ContentsPay-off / Straightening & Cutting / Main Extrusion Machine / Cooling & Anti-Oxidation System / Drying & Length Counting / Take-Up Machine / Hydraulic & Lubricating System / Electrical Control System.

※Remark: For details please contact us.

* Efficient Drawing Length: 10 M

* Nominal Drawing Force: 10 tons

* Bus Bar Production Range (Profile Specification): Width 30 - 170 mm/ Thickness: 3 - 30 mm

* Drawing Speed: 3 - 10 M/min (Inverter Controlled)

ContentsCenter Tracking Payoff With Brake / Pulling & Straightening Machine / Center Guiding Mechanism / Die Cooling & Lubricating / Main Drawing Machine / Saw & Cutting Machine / Transport Mechanism / Final Product Legnth Scaling & Sawing Machine / Hydraulic System / Electric Control System.

Automatic Fine Drawing & Recoiling Machine

The Scroll Automatic Drawing Machine uses for middle and small size copper bus bar and rod

scroll drawing and cutting, to increase the product surface hardness, elasticity & elongation.

The products mainly use for stamping process.

* Product Size Production Range: Width 10 - 100 mm/ Thickness 1 - 6 mm

* Drawing Speed: 5 - 15 M/min (Inverter Controlled)

* Production Capacity: 600 kg/hr; for size 25 x4 mm speed is 10 M/min

* Nominal Drawing Capacity: 12 tons

* Drawing Speed: 5 -15M/min

* Technological Process: Pointing → Payoff In Center → Straightening → Die Pushing Through → Hydraulic Pulling → Scroll Drawing Laying Off

ContentsBreak Type Auto Moving Pay Off Unit / Bracket For Centering Sensor / Straightening Device / Guidance & Positioning Unit / Die Holder Adjustment Unit / Die Holder Seat / Die Cooling & Lubrication System / Metering Unit / Online Following-Up Paper Mounting Device / Scroll Drawing Main Machine / Hydraulic Drawing System / Electrical Control System.

| ※Remarks: | 1.For details please contact us. 2.Above are our standard model, for special requirements are welcome! |

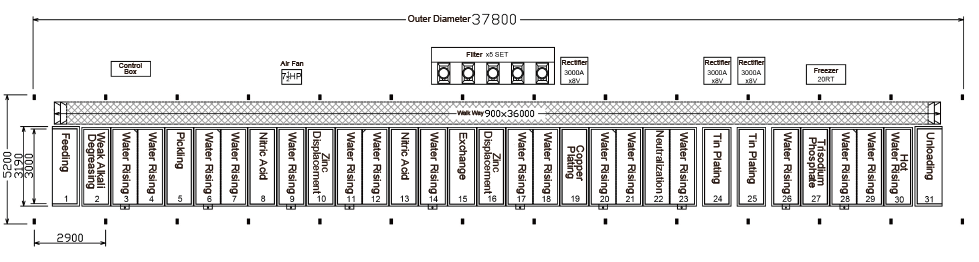

AUTO COPPER / ALUM. BUS BAR TIN PLATING EQUIPMENT

The Tin Plating Plant is specialized designed for copper& aluminum bus bar tin plating use, and according to different client's requirement we have designed in many ways and capacity.We welcome customers with special requirements, including different sizes of bus bar, different workpiece & different type of surface treatment.

* Max. Dimension of Copper: L 2800 x W 200 x H 15

* Drawing Speed: 5 - 15 M/min (Inverter Controlled)

* Production Capacity:600 kg/hr; for size 25 x4 mm speed is 10 M/min

* Total Power: 30 KW

| ※Remarks: | 1.For details please contact us. 2.We can accept customer's special requirements. |

| ※Remarks: | For other surface treatment, we also offer: 1. Automatic Rotary Type Hang-Plating Equipement. 2. Automatic Gantry Type Hang-Plating Equipment 3. Automatic Barrel Plating Equipment 4. R.C.B. & I.C. Plating Equipment 5. Anode Electrolysis Plating Equipment 6. Metal Surface Plating Equipment 7. Plastics Plating Equipment 8. Exhaust Treatment & Anti-Pollution Equipment 9. Automatic Film Equipment |

WIRE GALVANIZED WHOLE PLANT

For Wire Hot Dip Galvanizing Plant mainly we have two production capacity as (1) 3000 tons/month (3mm-36 wire passing) (2) 1,500 - 1,800 tons/month (3mm-24 wire passing). For standard commercial wire dia. 1.4 - 6.0mm. Our latest model's production process has 2 stages: (1) wire drawing (2) direct pay-off pickling& hot dip galvanizing. As for economic solution, 3 stages as (1) wire drawing (2) annealing (3) pay off pickling and hot dip galvanizing.

* Process: Payoff → Degreasing or Steel Wire Annealing → Rising → Pickling → Rising → Fluxing → Drying → Hot Dip Galvanizing → Cooling → Take up → Packing → Delivery

ApplicationA broad spectrum from cable, paper mills, gabion, fencing, engineering & construction industrial fields, to consumer market such as bolt & nut, wire mesh, stationery tray, fan guard, car seat & furniture products.

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

PIT TYPE ANNEALING FURNACE

* Furnace Type: PIT Type with Suspension Arm

* Loading: Drum ID600 x OD850 mm, 7 carriers, 14 - 15 MT/charge.

* Temperature: 680 - 720oC (max. 820oC)

* Auto Operate Cooling System

* Convection System: 20 HP 6 pole motor, water-cooled bearing block.

* Heating Wire Temperature: Max. 1400oC

* Fireproof Fiber Brick Temperature: 1260oC

* Furnace Cover: SUS310 5mm heat shield stuffed with fireproof fiber.

※Remark: For details please contact us.

Our Wire Rope Machine able forms and fabricates different types of single strand wire together into one complete rope. According to different requirement, it can be in spiral or stranded forms. Every complete wire rope has three main parts: 1) Forms a complete stranded wire for increasing wire rope’s strength. 2) Strand wires spirally intertwining on the core. 3) Forms a core for wire rope. Strength & tensile force can adapt to different uses in cars. We have different models of Wire Rope Machine to meet client’s demand.

Application-Automobile, vessel, agriculture machine, off-road vehicle accessories, based on customer’s request can be categorized into three categories: push-pull type, pull type, spiral type wire.

-Automobile application on gear shift lever wire, curtain draw line, sunroof draw line, stop watch wire, speedometer wire, elevator draw wire, gear lock pull wire, door locker pull wire, air conditioner controlling wire, bonnet pull wire, fuel tank pull wire, back mirror pull wire, trunk pull wire, accel wire, clutch wire, brake wire, seat pull wire, power seat pull wire, rotary meter wire, soft axis.

-Motorcycle application on clutch wire, accel wire, seat pull wire, brake wire, fuel tank pull wire, speedometer wire.

-Vessel application on direction line, engine control cable, reversing wire, gear wire, accel wire.

-Agricultural machinery control wire, brake wire, hydraulic flow control wire.

-Off-road vehicle wide range application on gear wire, snow car choke, control wire, etc.

FeatureOutstanding features, easy to operate, best performance.

※Remark: For details please contact us.

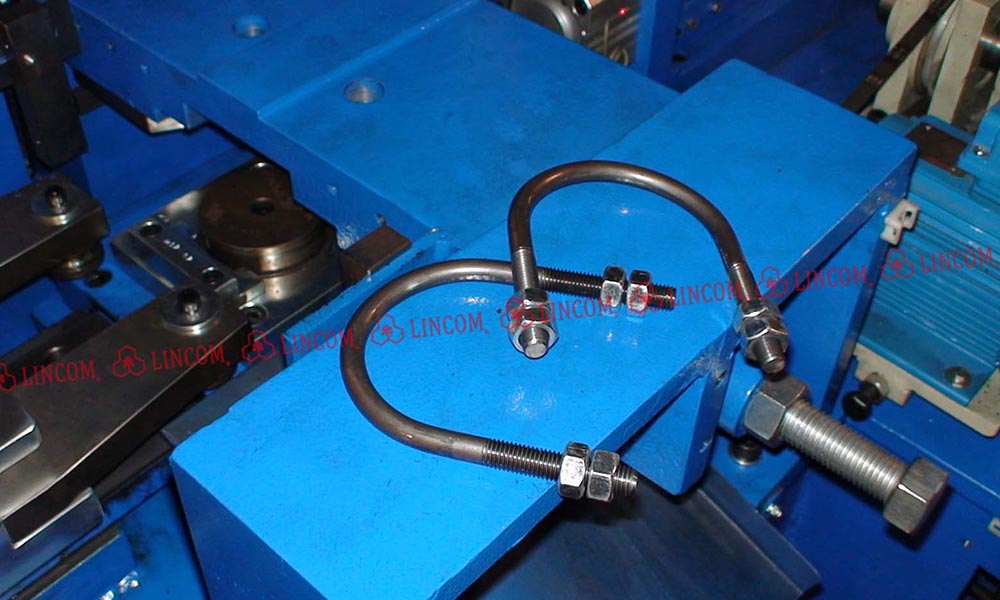

Fully Auto Double Side Chamfering, Threading and U Bolts Making Equipment

* Working Piece: M8 ~ M16, M10 - M 24

* Working Length: 100 ~ 600 mm

* Speed: 6 ~ 7 pcs/min.

Including:

* Feeding Device

* Automatic Stacker

* Automatic Moving Device

* Double Side Chamfering Device

* Automatic Threading Device

* Linear Slider

* Bending Device

* Hydraulic system

* Automatic PLC Control SYSTEM

* Working Process: Material Put in Stacker By manual → Auto Moving → Double Side Chamfering → Auto Transfer → Double Side Threading → Auto Transfer → U-Bending (U Bolt) → Automatic Runout

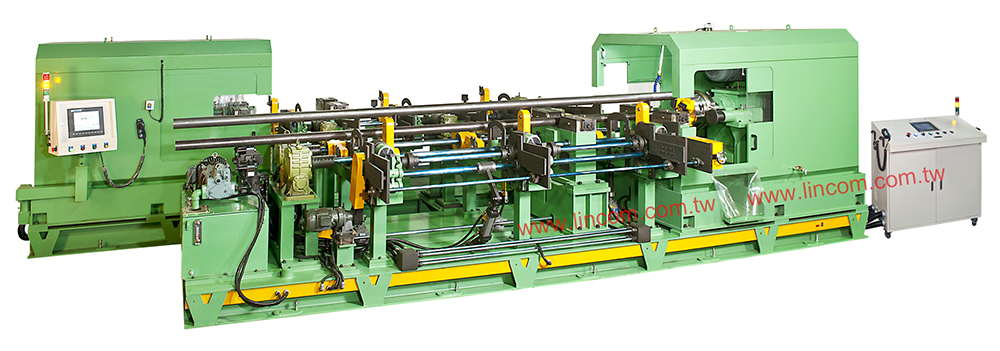

AUTOMATIC THREAD ROLLING MACHINE FOR STUD TREADED ROD

* Material: Mild steel & B7

* Size Range: 1/2" - 3 1/2"

* Length Range: 450-6000mm

* Store Tank Length: 3.5M

* Run out Stacker: 3.5M

* Rolling dia.: 50-120 mm

* Pitch: 2.0-12.0 P

* Rolling Length : 50 mm~any length

* Distance between Spindle Centers: 230-340 mm

* Rev. Speed of rolling dies: 20 - 60 RPM

Automatic Material Feeding and Output System

* Length: 6 M

ROD & TUBE PROCESSING MACHINERIES

ROD & TUBE CHAMFERING MACHINE

* Capacity: 3/8"-1", 1/2"-2", 1 1/2"-4", 3"-6", 6"-12", 8"-16"

* Capacity: 1/4"-6"

.jpg)

.jpg)

※Remark: For details please contact us.

ROD & TUBE THREADING MACHINE

| Auto Pipe Threading Machine | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Semi Auto Pipe Threading Machine | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Auto Nipple Threading Machine | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Auto Pipe Threading Machine For Both Ends | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Material: High Speed Steel. Various Types: PT, NPT, PS, NPS UNC, C, W, P.

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

Automatic Iron Pipe Cutting Machine

| Model | LAI-38 | LAI-65 |

| Dia. Of the Iron Pipe | φ6 ~ φ38mm | φ38 ~ φ65mm |

| Cut Off Length | 5~270mm (with extending table, max. can be up to 120mm) |

|

| Max. Cut Off Thickness | 10mm | 10mm |

| Spindle Motor | 2HP X 4P | 3HP X 4P |

| Feeding Motor | 1/4HP X 4P | 1/4HP X 4P |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

LAP-120 Automatic Pipe Cutting Machine

| Spindle Dia. | φ160(mm) |

| Spindle Motor | 5HP X 6P |

| Max. O.D. | φ110(mm) |

| Max. Length of the Cut Off | 500(mm) |

LSB-500 Steel Bar Ring Knot Processing Machine

| Max. Processing Diameter | 500(mm) |

| Max. Processing Length | 2000mm |

| Spindle Center Thimble | MT5 60 Degree |

| Ring Knot Processing Range | 45-160 |

| Spindle Motor | 5HP X 8P |

※Remark: We can accept customer's special requirements.

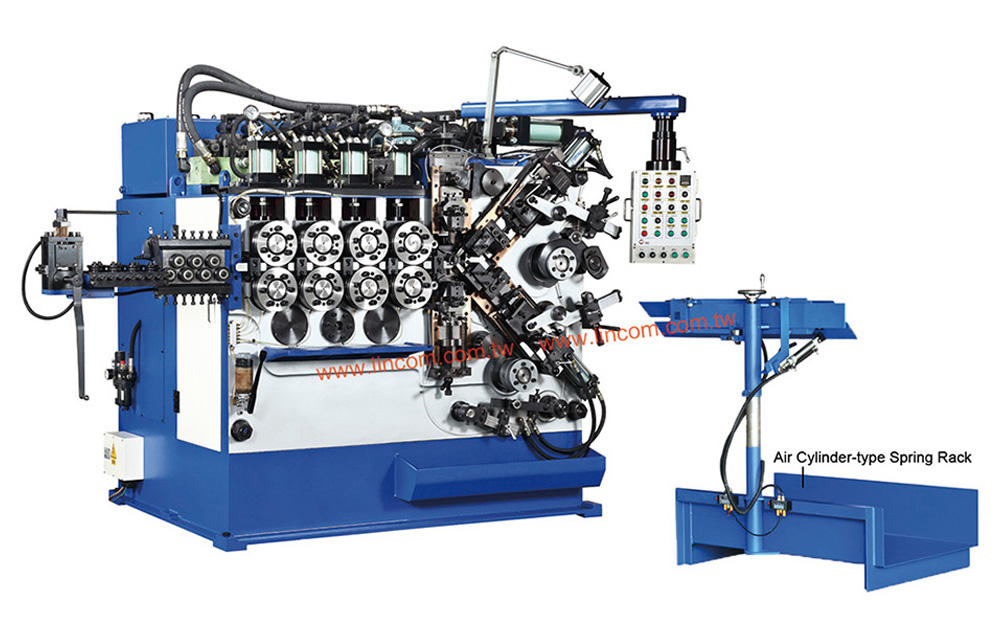

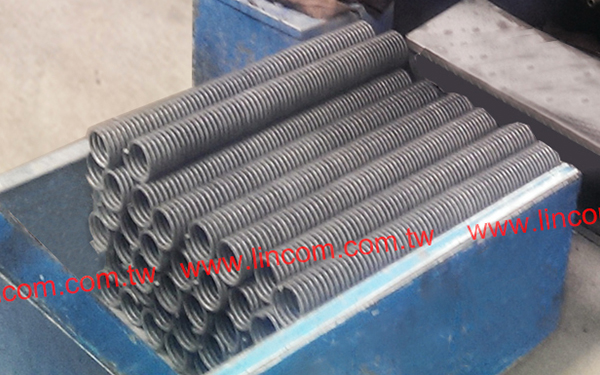

SPRING MAKING MACHINE

LINCOM specialized in provides heavy duty spring-making equipment, including spring-coiling, spring-end-grinding and associated equipment, for spring production for transportation vehicles, shutter doors and others heavy duty usage. With the advanced computer controlled technology, we assure our customers of top quality of their spring product.

ROLL SHUTTER DOORS SPRING MAKING MACHINE

Shutter Door Spring Making Machine:

* To feed wire by Air Clutch system for length of wire selecting at random.

* The Central Lubricant System.

* Unlimited length of spring is available.

| Model NO. | SD-80 | |

|---|---|---|

| Wire Capacity | Ø 2.0~ Ø 8.0 mm | |

| Max. Spring O.D. | Ø 80~ Ø 120 mm | |

| Feed Speed | 15、30、5、60 m/min | |

| Production Speed | 5~25 pcs/min | |

| Feed Length | 100~16000 mm | |

| Power Capacity | 7.5 kw | |

| Machine Body Dimension | Length | 2700 mm |

| Depth | 1550 mm | |

| High | 1840 mm | |

| Machine Occupied Area | Length | 4700 mm |

| Depth | 3600 mm | |

| Machine Weight | 3200 kgs | |

| Model NO. | SD-120 | |

|---|---|---|

| Wire Capacity | Ø 5.0~ Ø 12.0 mm | |

| Max. Spring O.D. | Ø 220 mm | |

| Feed Speed | 28、45、68、90 m/min | |

| Production Speed | 5~20 pcs/min | |

| Feed Length | 100~30000 mm | |

| Power Capacity | 16 kw | |

| Machine Body Dimension | Length | 3320 mm |

| Depth | 1900 mm | |

| High | 1900 mm | |

| Machine Occupied Area | Length | 5500 mm |

| Depth | 4000 mm | |

| Machine Weight | 6500 kgs | |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

CAR SHOCK ABSORBER SPRING MAKING MACHINE

* 3D-graphic operation interface

* To reduce material loss by 3D picture preview function

* To change the parameter directly by dragging way in line curves function

* Add cutting tool placement record picture to quicken adjust machine speed

* Build-in common types spring, just one touch the spring graph on screen to edit its parameter

| Wire Capacity | Ø 4.5mm~ Ø 10.0mm | |

|---|---|---|

| Max. Spring O.D. | Ø 150mm | |

| Feed Speed | 60m/min | |

| Production Speed | 120pcs/min | |

| Tensile Strength | 2000N/mm2 | |

| Spring index | ≧3 | |

| Machine Body Dimension | Length | 2800 mm |

| Depth | 2150 mm | |

| High | 2300 mm | |

| Safety Operation Location Area | Length | 14200 mm |

| Depth | 11000 mm | |

| Machine Weight | 7000 kgs | |

※Customers specific requirement are Welcome!

* Inner Oven: L 6000 x W 500 x H 150 mm

* Outer Oven: L 7976 x W 1126 x H 1869 mm

* Power Consumption: 80 KW

* Max. Setting Temperature: 420 °C

* Heat Air Circulation: AC 1/4 hp motor blower base, special design fan and Japan bearing.

* Transmission Device: AC 1 hp motor with reducer, inverter, transfer gear & adjustable base.

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |