FRICTION WELDING, BUTT & FLASH-BUTT WELDING MACHINE

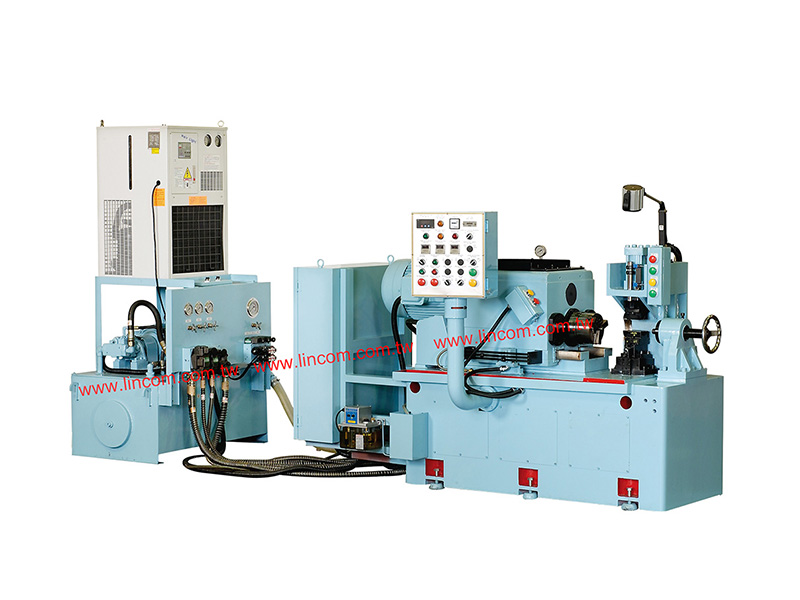

FRICTION WELDING MACHINE

Note: The machine follows in accordance with customer needs to optional

Frequency transformer added for spindle / Cutting system / Temperature detector / Automatic in-taker and discharger / Microcomputer proportional pressure regulator

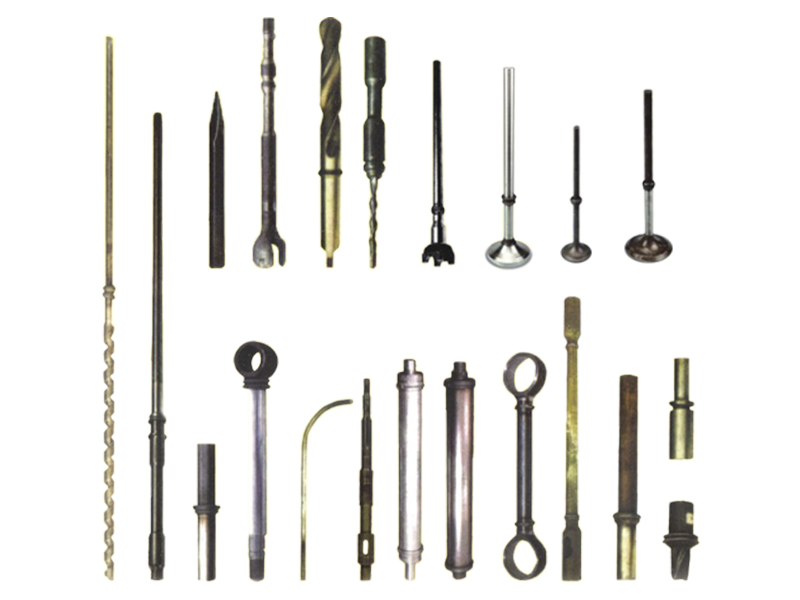

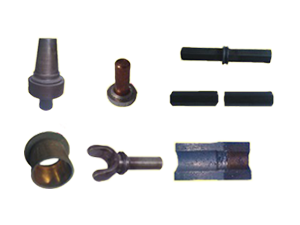

Friction welding is most suitable for the following

* Motorized vehicles

Control shaft, transmission shaft,engine valve, crank shaft, control pull rod, etc.

* Industrial materials

spindle, lathe milling machine knife stem, socket spanner, motor axle, connector, piston rod, etc.

* Constructional materials

Connecting device continuously of steel bar, tube and flange, planking and pipe round stick, diameter of different size and different types of metal, forge combination that cooperates with the spar and planking, etc.

Friction Welding machine SPECIFIACATIONS (LF system)

| SPECIFICATIONS HORIZONTAL (LF) | LF-15 | L-35 | L-70 | LF-100 | ||

| Welding material | Aluminum, Copper, Steel, Iron, Stainless Steel, Steel bar…(Use for LF & LMF) | |||||

| Welding Capacity | Round bar diameter (Max)(φmm) | Max. φ15 | Max. φ35 | Max. φ70 | Max. φ100 | |

| Pipe fittings (Max.)(φmm)(inch) | φ16 | 48.3 (1½”) | 88.9 (3”) | 140.3 (5”) | ||

| While friction and generating heat (TON) | φ15x230 | φ35x260 | φ75x300 | φ100x380 | ||

| While forging and pressurizing (TON) | 250 | a restricted | ||||

| Max. Thrust | While friction and generating heat (TON) | 0.95 | 7 | 13 | 25 | |

| While forging and pressurizing (TON) | 1.9 | 14 | 26 | 50 | ||

| Relationship of revolving spindle | Rotational speed of the spindle | 50Hz (rpm) | 2900 | 1450 | ||

| 60Hz (rpm) | 3440 | 1720 | ||||

| Spindle rotation Clutch | Way | Wet multiple magnetic clutch | ||||

| Torque (kgm) | 10 | 20 | 40 | 60 | ||

| Spindle stop Brake device | Way | Wet multiple break device | ||||

| Torque (kgm) | 10 | 20 | 80 | 100 | ||

| Breaking time (sec) | 0.2 | 0.2 | 0.3 | 0.3 | ||

| Diameter of the spindle bearing (mm) | 70 | 95 | 130 | 160 | ||

| Slide | Quick forwarding speed (mm/min) | 4800 | 3700 | 2800 | 2200 | |

| Quick returning speed (mm/min) | 9600 | 8600 | 5500 | 4000 | ||

| Max. distance of moving (mm) | 250 | 200 | 280 | 380 | ||

| Work piece Clamping | Top jig adjustment centre way | Hydraulic Simple opened the jig | ||||

| Clamping force | 1300 | 6000 | 12500 | 25000 | ||

| Clamping plate way | The level pair opened the synchronous jig | |||||

| Clamping force | 1900 | 1200 | 25000 | 50000 | ||

| Processing way | The size of adjusting (mm) | 0-15 | 0-15 | 0-15 | 0-15 | |

| Time adjusting (sec) | 0-999.9 | 0-999.9 | 0-999.9 | 0-999.9 | ||

| Motor | Spindle (kw) | 5.6 | 19 | 30 | 56 | |

| Hydraulic (kw) | 2.25 | 5.5 | 7.5 | 11.3 | ||

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

Friction Welding machine SPECIFIACATIONS (LMF system)

| SPECIFICATIONS VERTICAL(LMF) | LMF-15 | LMF-35 | LMF-70 | LMF-100 | ||

| Welding Capacity | Round bar diameter (Max)(φ mm) | Max. φ15 | Max. φ35 | Max. φ70 | Max. φ100 | |

| Pipe fittings (Max.)(φ mm)(inch) | φ16 | 48.3 (1½”) | 88.9 (3”) | 140.3 (5”) | ||

| Rotate length of the side material (Max.) (mm) | φ15x230 | φ35x220 | φ75x300 | φ100x380 | ||

| Length of the regular side material (mm) | 400 | 600 | 800 | 1200 | ||

| Max. Thrust | While friction and generating heat (TON) | 0.88 | 6 | 13 | 25 | |

| While forging and pressurizing (TON) | 1.76 | 12 | 26 | 50 | ||

| Relationship of revolving spindle | Rotational speed of the spindle | 50Hz (rpm) | 2900 | 1450 | 950 | 950 |

| 60Hz (rpm) | 3440 | 1720 | 1140 | 1140 | ||

| Spindle rotation Clutch | Way | Wet multiple magnetic clutch | ||||

| Torque (kgm) | 10 | 20 | 40 | 60 | ||

| Spindle stop Brake device | Way | Wet multiple break device | ||||

| Torque (kgm) | 10 | 20 | 80 | 100 | ||

| Breaking time (sec) | 0.2 | 0.2 | 0.3 | 0.3 | ||

| Diameter of the spindle bearing (mm) | 70 | 95 | 130 | 160 | ||

| Slide | Quick forwarding speed (mm/min) | 4800 | 3700 | 2800 | 2200 | |

| Quick returning speed (mm/min) | 9600 | 8600 | 5500 | 4000 | ||

| Max. distance of moving (mm) | 150 | 280 | 280 | 380 | ||

| Work piece Clamping | Top jig adjustment centre way | Hydraulic Simple opened the jig | ||||

| Clamping force | 1300 | 7000 | 13000 | 25000 | ||

| Clamping plate way | The level pair opened the synchronous jig | |||||

| Clamping force | 1900 | 5000 | 13000 | 25000 | ||

| Processing way | The size of adjusting (mm) | 0-15 | 0-15 | 0-15 | 0-15 | |

| Time adjusting (sec) | 0-999.9 | 0-999.9 | 0-999.9 | 0-999.9 | ||

| Motor | Spindle (kw) | 5.6 | 19 | 30 | 56 | |

| Hydraulic (kw) | 2.25 | 5.5 | 7.5 | 11.3 | ||

| The pressure outputs the way | Proportion way or Hand adjust way | |||||

| Hydraulic oil temperature cooling system | Automatic temperature-controlled cooler (Compress the refrigerant) | |||||

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

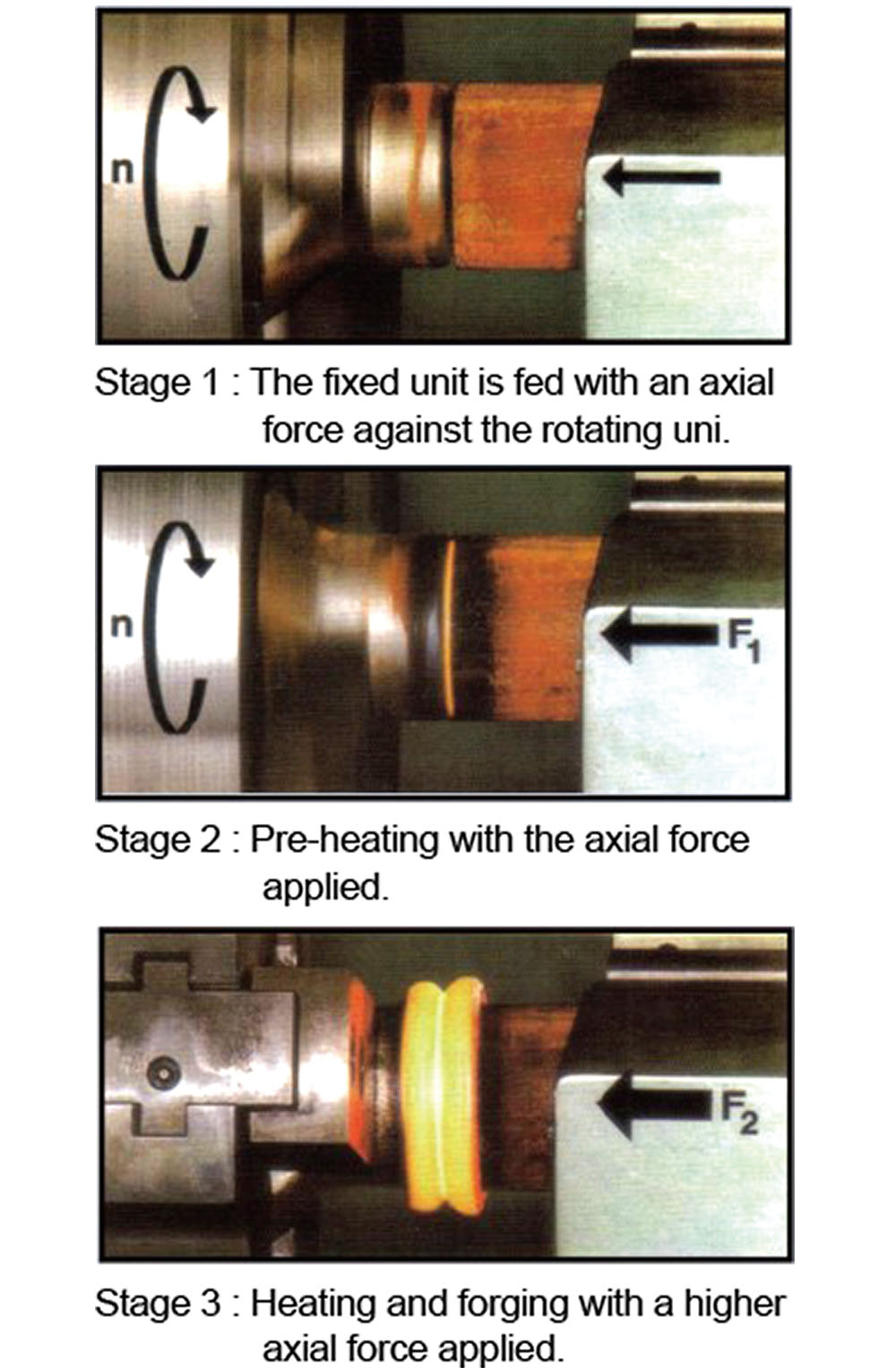

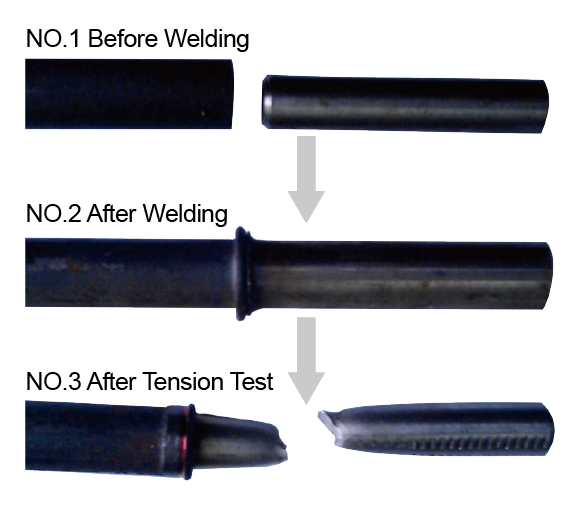

The tension test shows that the welded unit fails somewhere other than the welded point.

PRINCIPLE

It is that one "solid state" welds the method, it regard frictional heat as the heat source, motor via the rotation friction of the relativity and exert the axial pressure, heat the work piece surface to the plasticity state, construct and join the same kind or the different kind of metal firmly with the pressure at the same time.

CHARACTERISTIC & ADVANTAGE

- No external heat or additional welding rod is needed. Heat is evenly generated and distributed between the surfaces of work pieces.

- The strength of the welding point is greater than the or original material(s). The welding is conducted with high accuracy without altering the properties of the original material(s).

- No electric arc, spark, smog, or toxicant is produced because no fuel or filling material is necessary at the time of processing, which leads to a better working environment.

- Compared to other types of welding, the surface is cleaner because of the shifting friction and replacement of the surface layer.

- Friction welding can be conducted with extremely high efficiency, which makes it especially suitable for automation for mass production.

- Friction welding has become one of the most reliable and economical methods of jointing metals. It has been extensively applied in order to reduce the cost of production and improve the quality of welding.

- Friction welding can be applied to most engineering materials. Different metals can also be effectively jointed using this method. The relative sliding displacement after welding is minute and can fulfill any testing requirement.

- In most cases, the strength of the welding point is equal to or greater than the original two metal pieces.

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

BUTT WELDER & FLASH-BUTT WELDING MACHINE

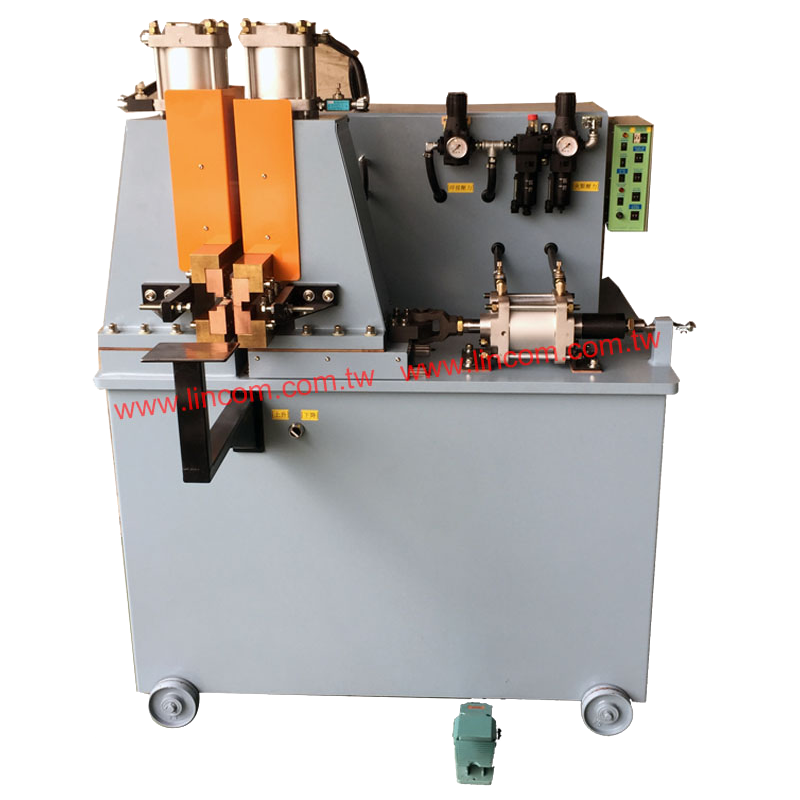

Pneumatic Butt Welder

Able to Butt Weld Various Metal.

Iron Bar, Chain, Scissor Handle, Copper Bar, Galvanized Steel Sheet... Hardware Products.

Butt Welding Machine, Air Hydraulic Type

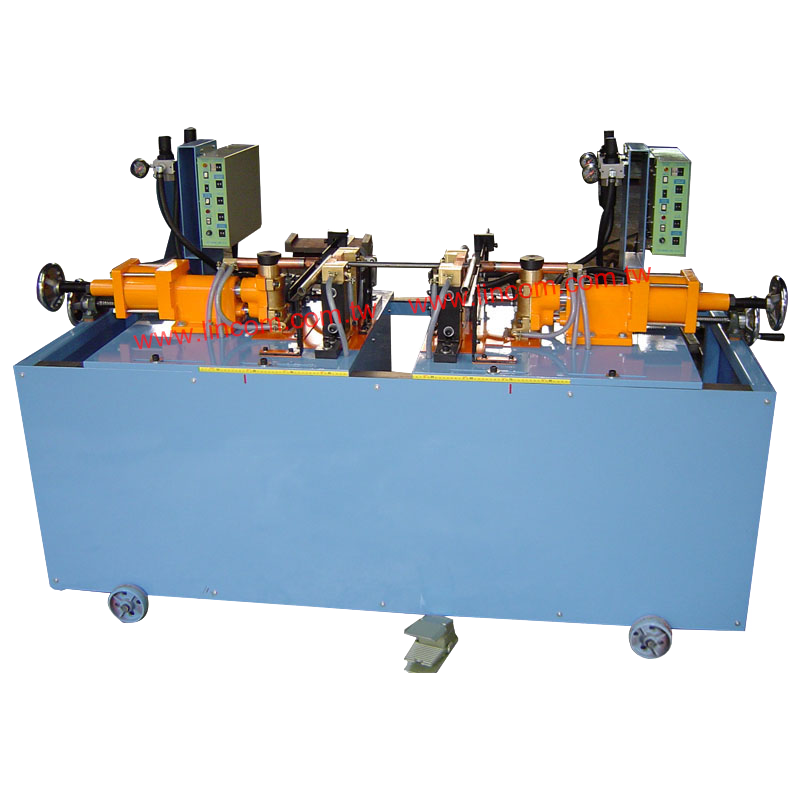

Butt Welding Machine, H Type

Butt Welding Machine, Hydraulic Type for Big Dia. Steel Rim or Bar

| Capacity Model |

Rated Capacity | Power | Rated Frequency | Max. Welding Current | Butt Welding Dia. |

| KVA | V | HZ | A | m/m ψ | |

| LBW-300 | 30 | 220/440 | 50/60 | 14000 | 2~4 |

| LBW-500 | 50 | 220/440 | 50/60 | 18000 | 2~6 |

| LBW-800 | 80 | 220/440 | 50/60 | 22000 | 3~10 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

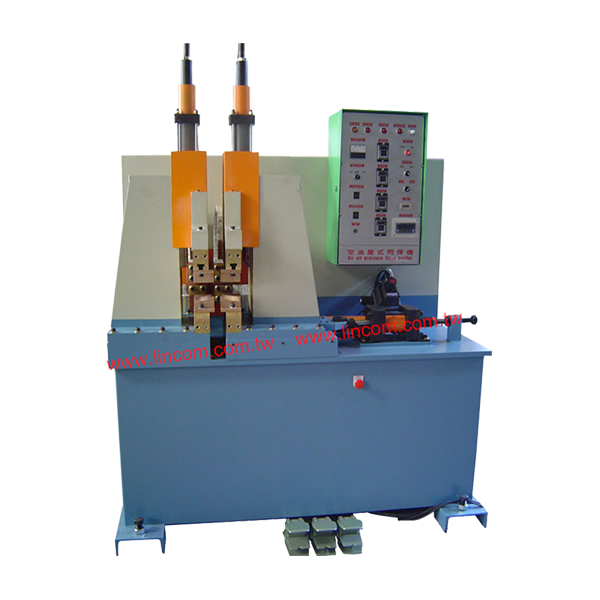

Hydraulic Flash Butt Welder

Application:General Hardware Products, Iron Pipe Butt Weld, Iron Pipe Furniture, Wheel Rim For Automotive, Automotive Accessories, Stainless Steel Bar, Knife Holder, Steel Ring, Iron Plate, etc.

Flash-Butt Welding Machine for Pipe, Hydraulic Type

| Capacity Model |

Rated Capacity | Power | Rated Frequency | Max. Welding Current | But Welding Capacity | Cooling Water Volume |

| KVA | V φ1 | HZ | A | t ×φm/m | L/min | |

| LFBW-800 | 80 | 220/440 | 50/60 | 22000 | 1.5×22 | 15 |

| LFBW-1000 | 100 | 220/440 | 50/60 | 25000 | 1.5×25 | 15 |

| LFBW-1500 | 150 | 220/440 | 50/60 | 32000 | 2.0×32 | 20 |

| LFBW-2000 | 200 | 220/440 | 50/60 | 38000 | 2.0×38 | 20 |

| LFBW-2500 | 250 | 220/440 | 50/60 | 45000 | 2.5×42 | 25 |

| LFBW-3000 | 300 | 220/440 | 50/60 | 53000 | 2.5×50 | 25 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |