WATER HEATER(BOILERS) & OIL FILLED RADIATOR HEATER PLANT

WATER HEATER (BOILER) PRODUCTION LINE

* Lincom supplies the entire Water Heater Boiler Production Line base on over 30 years of experience. Besides offering the turnkey solution full line, we also help those clients who are producing already to upgrade their current production line. Base on customer's requirement, Lincom provides not only the equipment, but also the design, factory layout, installation & workers training.

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/water-boiler-production-full-line.jpg)

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/water-heater.jpg)

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/two-roll-bending-machine.jpg)

Two Roll Bending Machine

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/straight-line-welder.jpg)

Straight Line Welder

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/water-boiler-tank-inner-tank-body-welding.png)

Horizontal Welding Machine

-oil-filled-radiator-heater-whole-plant/automatic-seam-welding-machine-for-boiler/01.jpg)

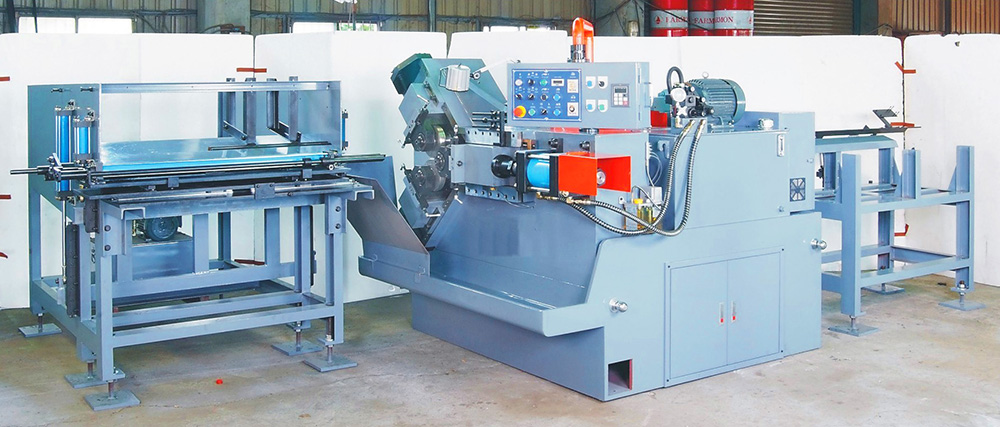

Auto Line For Body Making From Sheet, Rolling & Welding

-oil-filled-radiator-heater-whole-plant/automatic-seam-welding-machine-for-boiler/boiler-making-02.jpg)

Top/ Bottom Deep Drawing

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/end-cap-trimer-and-punch.jpg)

End Cap Trimer and Punch

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/end-cap-circular-cutter.png)

End Cap Circular Cutter

-oil-filled-radiator-heater-whole-plant/automatic-seam-welding-machine-for-boiler/boiler-making-01.jpg)

Robot Welder

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/horizontal-welding-machine.png)

Horizontal Welding Machine

-oil-filled-radiator-heater-whole-plant/automatic-seam-welding-machine-for-boiler/8-argon-auto-welder-for-heater-tank.png)

Argon Auto Welder for Heater Tank

※Customers specific requirement are Welcome!

STEEL COIL DISC AUTO BLANKING MACHINE

This Coil Disc Cutting Line, it is widely used in many different need Cycle deep drawing purpose which requirement quantity for Automation, labors & material saving ... cost down... Customers any specify requirement are Welcome.

-oil-filled-radiator-heater-whole-plant/disc-material-auto-blanking-line/steel-coil-disc-auto-blanking-machine-01.jpg)

-oil-filled-radiator-heater-whole-plant/disc-material-auto-blanking-line/steel-coil-disc-auto-blanking-machine-02.jpg)

-oil-filled-radiator-heater-whole-plant/disc-material-auto-blanking-line/steel-coil-disc-auto-blanking-machine-03.jpg)

-oil-filled-radiator-heater-whole-plant/disc-material-auto-blanking-line/steel-coil-disc-auto-blanking-machine-04.jpg)

-oil-filled-radiator-heater-whole-plant/disc-material-auto-blanking-line/steel-coil-disc-auto-blanking-machine-05.jpg)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

SHEET MATERIAL DISC CUTTING

Steel Sheet Disc Cutting Machine

* Sheet Thickness: 3.2 mm

* Min. Cutting Dia.: φ 300 mm

* Max. Cutting Dia.: φ 1200 mm

* Throat Depth: 265 mm

※Customers specific requirement are Welcome!

-oil-filled-radiator-heater-whole-plant/sheet-disc-material-cutting-machine/sheet-material-disc-cutting-01.jpg)

-oil-filled-radiator-heater-whole-plant/sheet-disc-material-cutting-machine/sheet-material-disc-cutting-02.jpg)

WATER HEATER(BOILER) INNER TANK PRODUCTION

* Workpiece Size: dia. 410 mm

* Height : For 40 Ltrs 143mm / for 50 Ltrs 222mm / for 80 Ltrs 335mm

* This line adopts robot (machine hand) and automation system to optimise customer's operation with automation working in line. From servo feeding to finish welding product runout, all processes in line.

* Robot is main control, connecting Power Press/ Hydraulic Power Press Discharge Conveyor/Hydraulic Power Press Machine/Trimming Machine/Tank Expanding Machine in line.

* Control is PLC with HMI . Robot transfer by servo motor.

-oil-filled-radiator-heater-whole-plant/steel-socket-making-machine/inner-tank-01.jpg)

-oil-filled-radiator-heater-whole-plant/steel-socket-making-machine/inner-tank-02.jpg)

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/30litr.jpg)

Inner Tank Production

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/50litr.jpg)

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/80litr.jpg)

-oil-filled-radiator-heater-whole-plant/water-heater-(boilers)/boiler-outer-tank.png)

-oil-filled-radiator-heater-whole-plant/machine-&-dies-for-boiler-inner-tank/20180314_171022.jpg)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

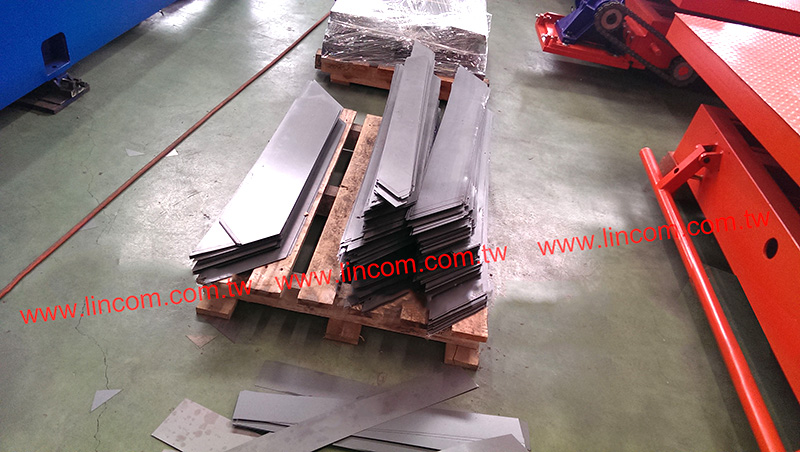

SLITTING / CUT TO LENGTH (SHEET PREPARING)

* Material: HR & CR Steel, G.I. Steel, Prepainted Coil Steel, Stainless Steel.

* Thickness: 0.6 - 3.0 mm (Stainless Steel 0.6 - 2.0 mm)

* Workable Width: Coil 1250 mm, Max. Strips is 3 strips.

* Speed: 15 - 20 M/min

* Coil weight: Max. 7 Tons

* PLC Control Box: PLC system controlled with HMI touchscreen.

-oil-filled-radiator-heater-whole-plant/simple-slitting.png)

※Customers specific requirement are Welcome!

-oil-filled-radiator-heater-whole-plant/simple-slitting-machine-line.jpg)

-oil-filled-radiator-heater-whole-plant/simple-slitting-machine.jpg)

-oil-filled-radiator-heater-whole-plant/simple-slitting-and-shearing.jpg)

NIPPLE AUTO MAKING MACHINE(PIPE AUTO FEEDING, THREADING & CUTTING)

For 1/2" , 3/4", 1" Pipe (Nipple) Length 14 cm

* Material: Galvanized and Black Steel Pipe

* Speed: 1 pc/20 - 22 sec

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

-oil-filled-radiator-heater-whole-plant/nipple-auto-making-machine/05.jpg)

-oil-filled-radiator-heater-whole-plant/nipple-auto-making-machine/01.jpg)

-oil-filled-radiator-heater-whole-plant/nipple-auto-making-machine/03.jpg)

-oil-filled-radiator-heater-whole-plant/nipple-auto-making-machine/02.jpg)

-oil-filled-radiator-heater-whole-plant/nipple-auto-making-machine/04.jpg)

STEEL SOCKET MAKING MACHINE(CHAMFERING & THREADING)

FOR SOCKET 1/2" AND 1 1/4"

* Speed: about 1-2 pcs/min.

For 1-1/4" Socket is about 1- 2 pcs/min

Working Process: Piece Loading → Surfacing, Chamfering, Ring Gap → another side Facing, Chamfering & OD Sizing → ID Sizing → Threading → ready piece

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

-oil-filled-radiator-heater-whole-plant/steel-socket-making-machine/steel-socket-making-machine.jpg)

ENAMELING COATING LINE FOR BOILER INNER TANK ...

For Enameling Coating, we have both Wet Process Enameling Coating & Powder Process Enameling Coating due to years experience our design in easy adapt operation and low energy consumption.... and which are widely use in Water Heater Inner Tank, Gas Cooker, Electronic Oven, Barbecue grills & Building out-wall tile...etc.

1. Pre-Treatment 1 Set

2. Complete Enamel Grinding Equipment 1 Set

3. Enameling Rotating Machine 1 Set

4. Hanging Type Tunnel Drying Equipment 1 Set

-oil-filled-radiator-heater-whole-plant/coating/boiler-enameling-coating-line.jpg)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

-oil-filled-radiator-heater-whole-plant/coating/09.jpg)

-oil-filled-radiator-heater-whole-plant/coating/08.jpg)

-oil-filled-radiator-heater-whole-plant/coating/06.jpg)

-oil-filled-radiator-heater-whole-plant/coating/04.jpg)

-oil-filled-radiator-heater-whole-plant/coating/03.jpg)

-oil-filled-radiator-heater-whole-plant/coating/02.jpg)

-oil-filled-radiator-heater-whole-plant/coating/snapshot-l-01.jpg)

-oil-filled-radiator-heater-whole-plant/coating/snapshot-l-02.jpg)

-oil-filled-radiator-heater-whole-plant/coating/01.jpg)

-oil-filled-radiator-heater-whole-plant/coating/05.jpg)

OIL-FILLED HEATER MACHINERY

Power Press & Stamping Die for Heater Blade/ Power Press & Stamping Die for Disc/ Auto Seam Welding Machine / Auto Seam Welding Machine / Spot Welding Machine/ Air Leak Testing Machine

-oil-filled-radiator-heater-whole-plant/oil-filled-heater-machinery/oil-filled-heater-machinery01.jpg)

-oil-filled-radiator-heater-whole-plant/oil-filled-heater-machinery/oil-filled-heater-machinery02.png)

-oil-filled-radiator-heater-whole-plant/oil-filled-heater-machinery/oil-filled-heater-machinery03.jpg)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

LPG (GAS) CYLINDER, FIRE EXTINGUISHER... HOUSEHOLD APPLIANCES PLANT

LPG (GAS) CYLINDER, FIRE EXTINGUISHER... HOUSEHOLD APPLIANCES PLANT

For LPG(Gas) cylinder Production, base on clients budget & capacity we have different arrange way., but mainly into three process; as

Collar Fabrication

- Blanking & cutting → Rolling → Forming → Auto Welding of collars to top shells

Base Ring Fabrication

- Blanking → Rolling → Welding joint → forming → Auto welding of Base rings to bottom shells

Main Shells(three parts) of cylinder fabrication

- Steel Coil Shearing → Rolling-Automatic long seam welding → Pre → assemble of top & bottom end and shells → Auto Circumferential seam welding

Top & Bottom end fabrication

- Blanking → Deep drawing → Top Trimming → Punching valve neck hole of top → Trimming and beading of bottom end.

-cylinder,-fire-extinguisher-household-appliances-plant/LPG-cyclinder-manufacturing-process.jpg)

※Customers specific requirement are Welcome!

-cylinder,-fire-extinguisher-household-appliances-plant/LPG-cyclinder-manufacturing-machine.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/gas-cylinder-05.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/gas-cylinder-04.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/01.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/03.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/gas-cylinder-01.jpg)

FIRE HOSE RACK & REEL CABINET PRODUCTION...

Robot with robot-use digital control welder

* Work Piece Size: 800 x 800 mm

* Work Piece Material: Carbon Steel

* Working Table: The workpiece is 90 degrees on both sides and the height of the baffle is 200mm (table height can be adjusted).

* Workpiece Fixing: Twin guide cylinder two side pressing stroke 100mm on the working surface (by manual valve control).

Contents:1. 6-axis multi-purpose robot

2. CO2/MIG inverter

3. working table with fixture for cabinet

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-hose-rack.png)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-hose-cabinet-01.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-hose-cabinet-02.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-reel02.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-reel03.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-reel01.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-reel05.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-reel04.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/hose-real06.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-hose-cabinet-03.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-hose-cabinet-05.jpg)

FIRE EXTINGUISHER AND AIR TANK PRODUCTION...

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/1.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/1a.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/2.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/3a.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/4.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/4a.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/5.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/5a.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/6.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher-horizontal-04.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher-horizontal-01.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher-horizontal-02.jpg)

-cylinder,-fire-extinguisher-household-appliances-plant/fire-extinguisher/fire-extinguisher/8.jpg)

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

STEEL DRUM FULL PLANT / DRUM CLEAN & RENEW / STEEL DRUM CUTTER & CURLER /...EQUIPMENT

Lincom except well know in Steel Drum Full Plant set up, Due to years experience in this field, so we also has developed many different special purpose machine related to Steel Drum purpose... such as ; Steel Drum Cutter & Curler System, Drum Cutter, Steel Drum Washer & Crusher... contact us for details or send us your any special requirement...

※For details or more related please contact us.

SCAFFOLDING FORMWORK & CONSTRUCTION FIELD WHOLE PLANT

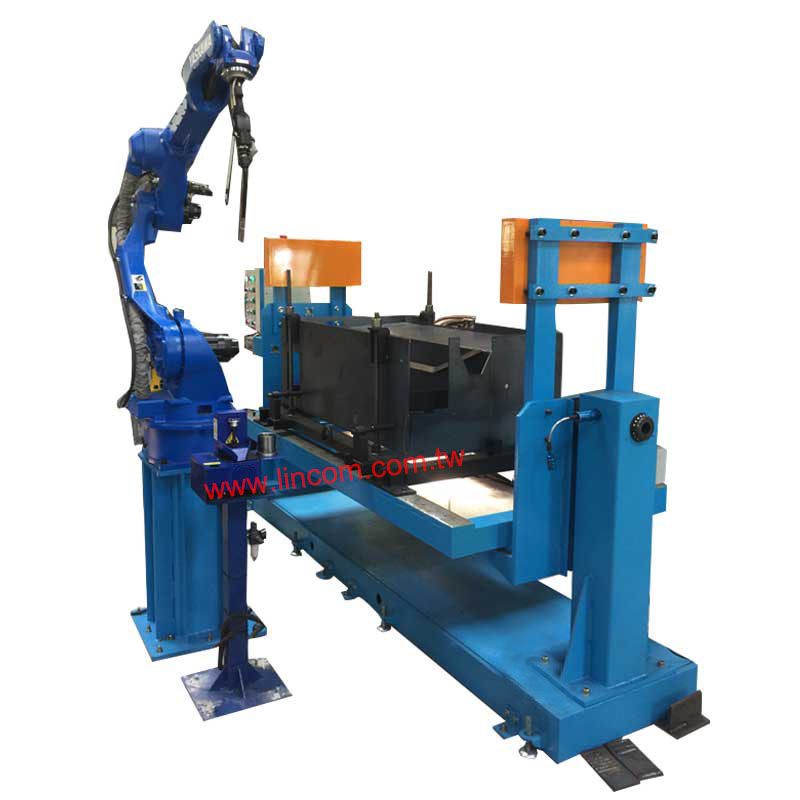

ROBOT AUTO WELDER FOR SCAFFOLDING FRAME

HYDRAULIC POSITION TURN TABLE 2SET

* Position and turn table

* Connection with robot welding

* Can choice multi setting robot welding signal

* Turning angle 0-180℃ choice

* Easy operation and position precision

* Control can choice with A and B table when A table welding, B table turn over.

* Max. length 2000mm, width 600mm

ROBOT WELDING 1SET

* Set welding another set turning

* Attached one set of welding machine

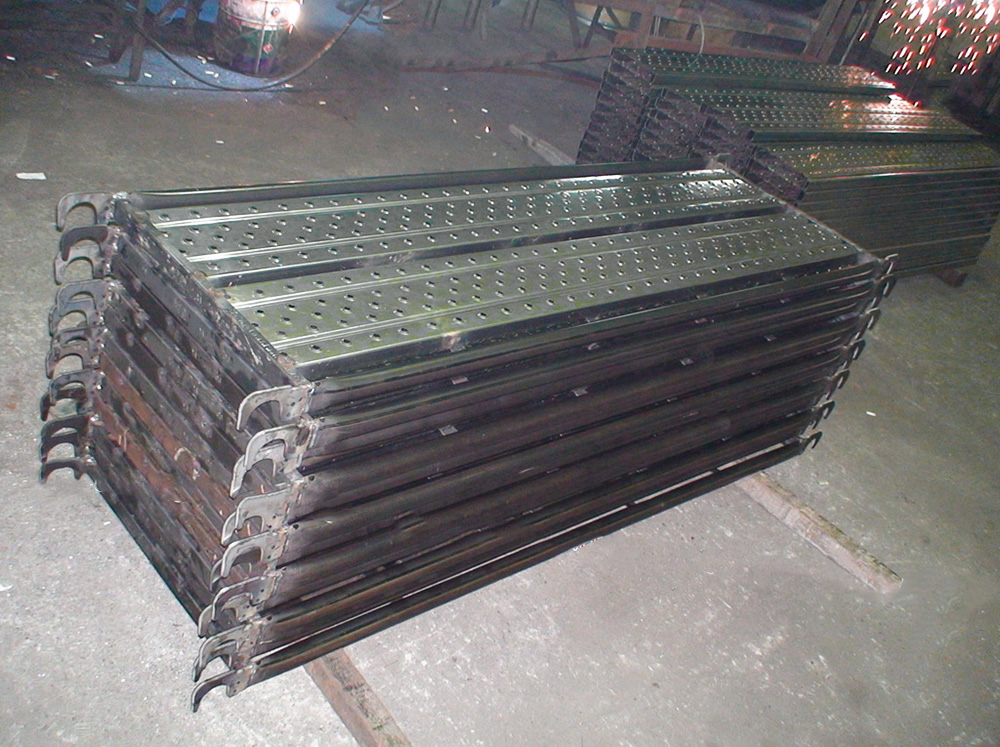

STEEL PLANK AUTO ROLL FORMING MACHINE

* Material: Galvanized Steel, Cold Rolled Steel

* Thickness: 2.5mm

* Length: 0.5/0.8/1.8/3.3/4M

* Width: 225mm

Contents:Uncoiler / Roll Forming Machine / Punching Hole Device / Forming Cutting Device / Hydraulic System / Run Out Table / Plc Control

ROBOT & NC POSITIONER FOR PLANKS

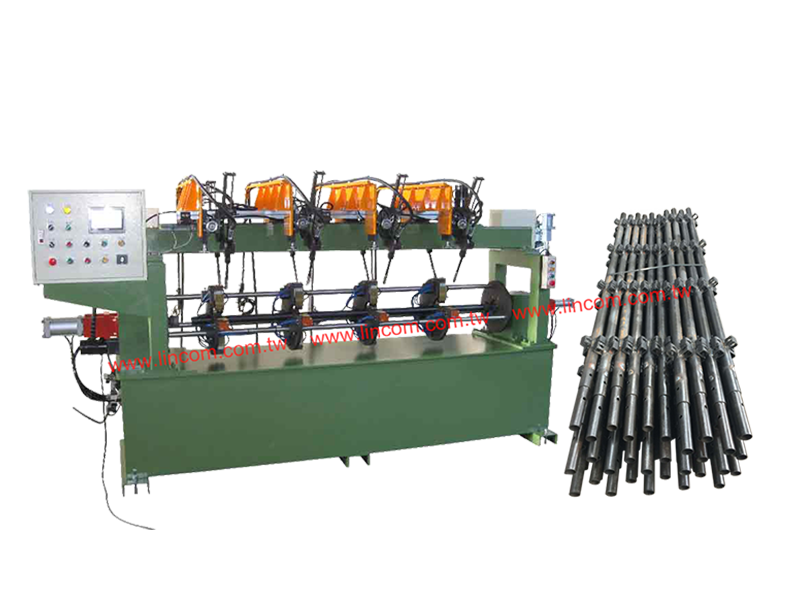

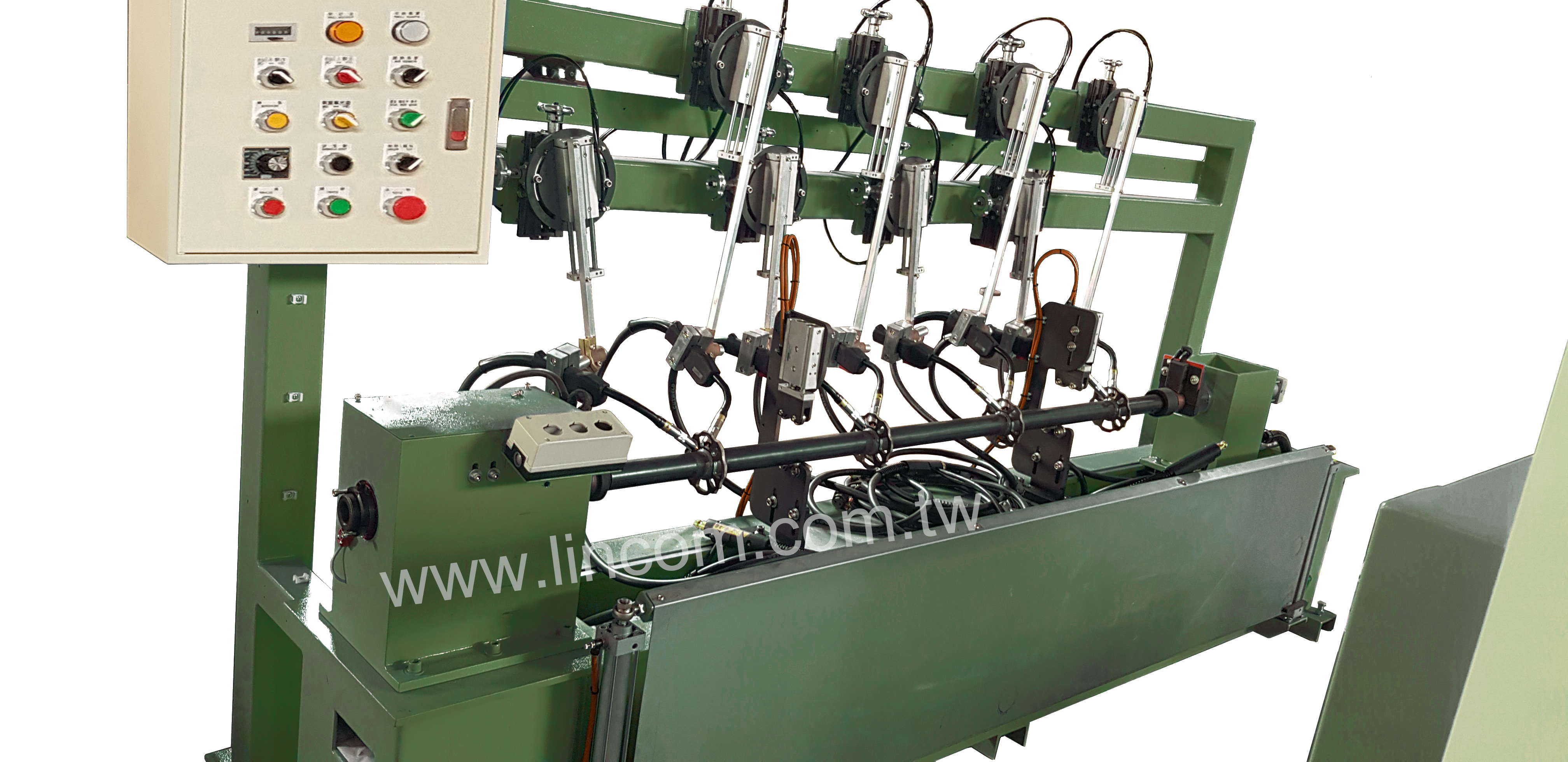

POST AND CUP LOCK AUTO WELDING MACHINE

* Use fix jig, 10gun auto spot welding.

* With manual and auto choice.

* Can choice, single/multi gun welding.

* Front base match with clamper, fast clamping cap, tighting and position.

* Clamping base matches with air cylinder, eject production, easy operation & can be easily adjusted as per prop length.

* Welding angle adjustment can do up and down, left and right adjust, stroke 50mm

* Welding gun up and down air cylinder stroke 75mm, for welding gun up and down.

* Front and rear base same time rotation be sure welding equal.

* Control Type: PLC with HMI easy operation and maintance.

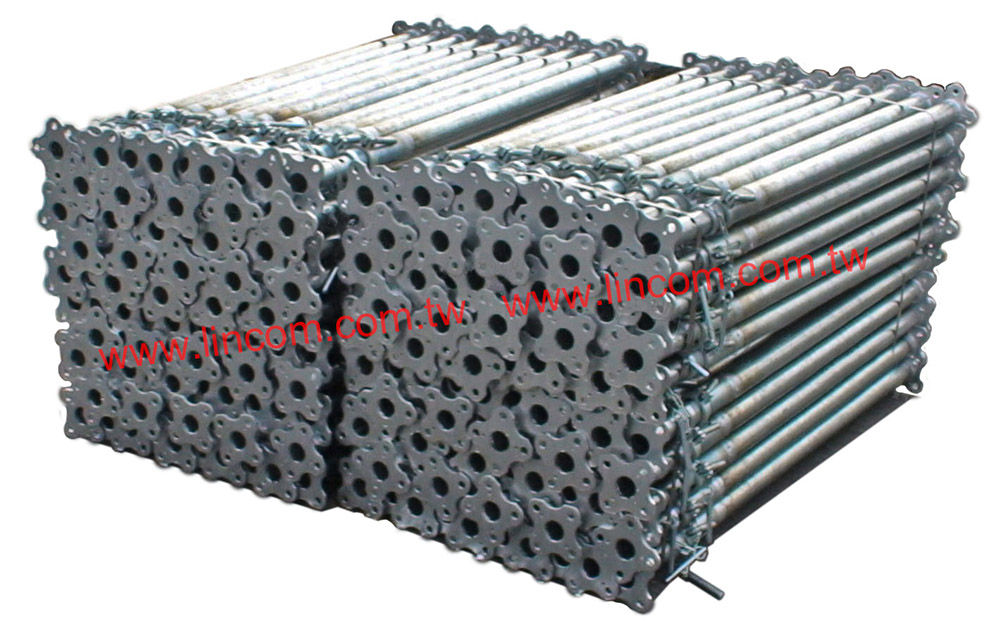

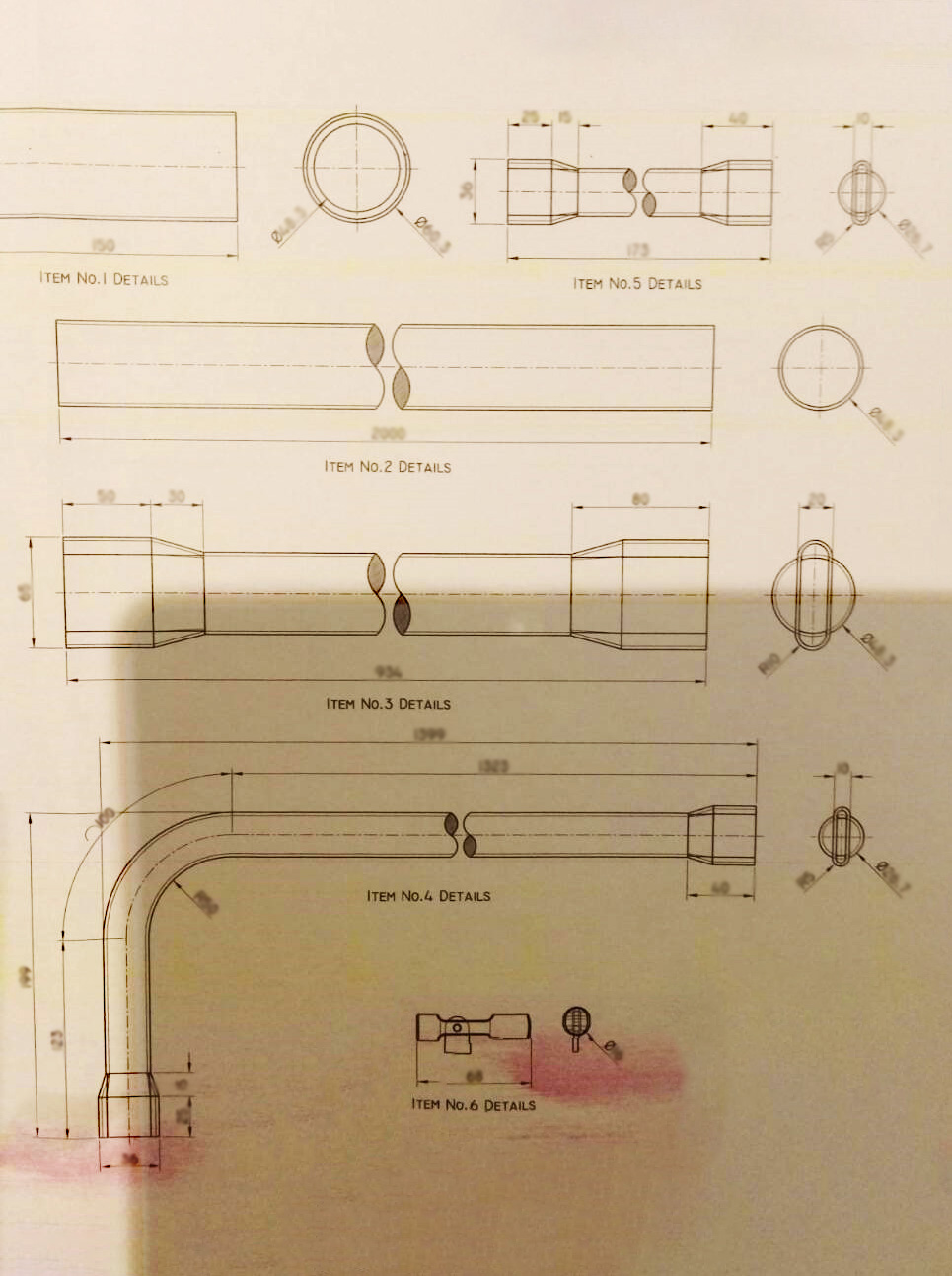

SCAFFOLDING PROP & JACK MAKING EQUIPMENTS

a. Automatic Feeder/Runout

b. Hydraulic Triple - Rolling Dies Thread Rolling Machine

c. Press with Punching Die for Collar Pin Hole

d. Automatic Drilling Machine

e. Automatic Welding Machine

a.Automatic Feeder/Runout

* Length: 2 M

* Hydraulic Motor:3 HP

b.Hydraulic Triple -Rolling Dies Thread Rolling Machine

* Rolling dia.: 25 - 125 mm

* Pitch: 0.75 - 6.0 P

* Processing Capacity: 10 pcs/min.

c.Props Pipe Auto Drilling Machine

* Main Motor: 15 HP x 2 P

* Hydraulic Motor: 7 1/2 HP x 1 P

* Speed: Drilling 13 holes one side at once, 26 holes per piece. 1 pc/90 - 120 sec.

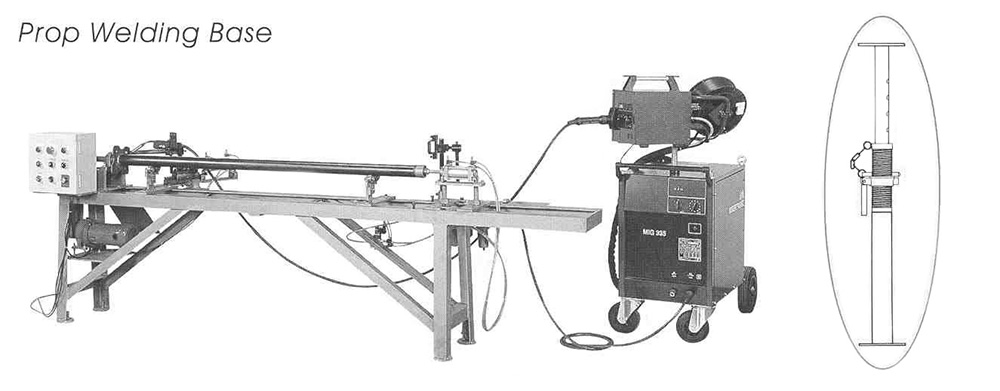

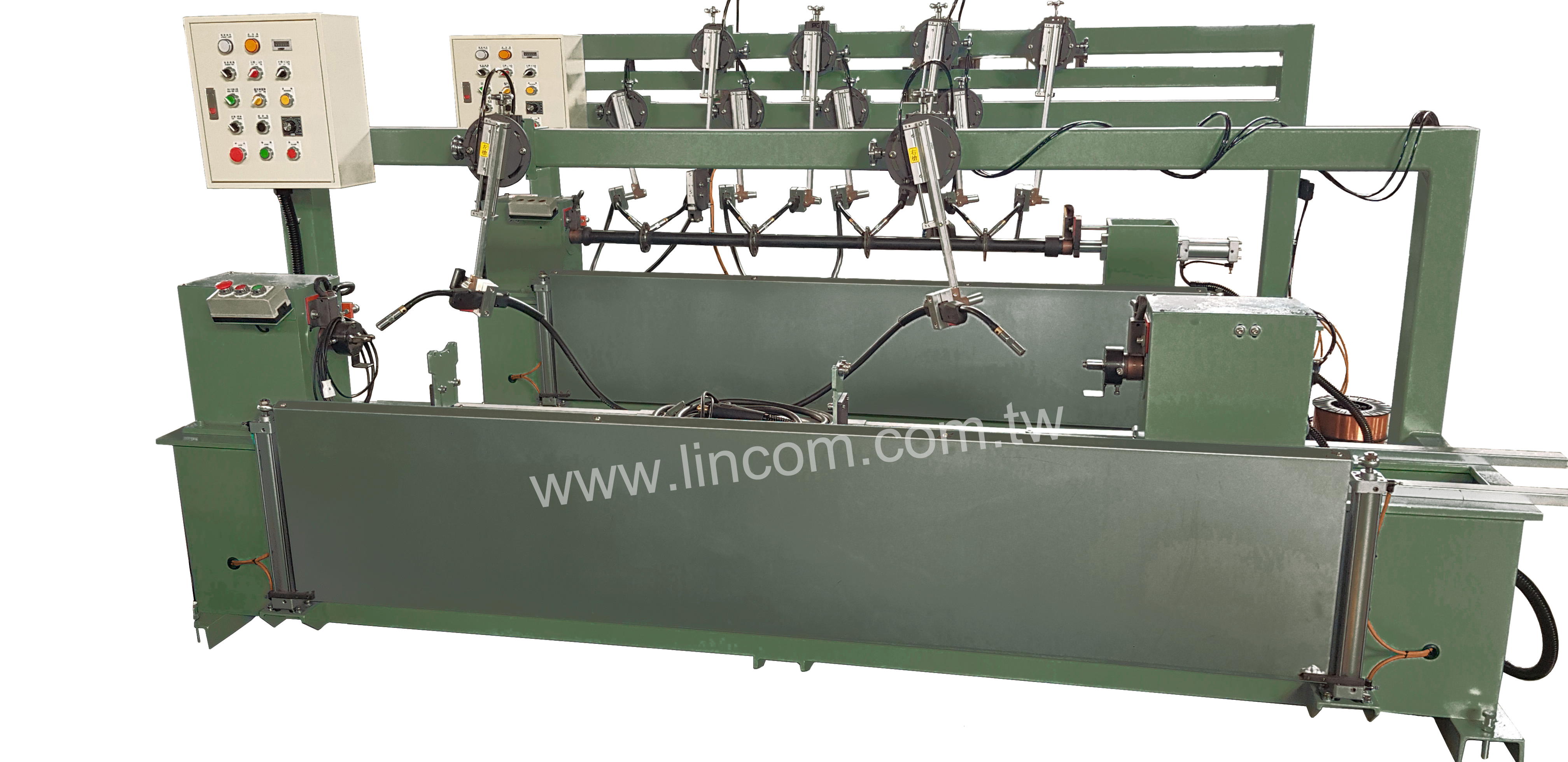

d.Automatic Welding Machine for Prop & Jack

Horizontal Type Auto Rotatory Welding Machine

* Material Thickness: 5 - 7 mm

* Working Piece Length: 1500 - 3500 mm

* Working Piece Dia.: φ 48 mm, φ 50 mm

SOLDIER ROLL FORMING & PUNCHING LINE

* Material: HR, CR, GI, Coil

* Thickness: 3mm

* Production Speed: 4-6M/min (with punching & cutting)

Contents:Hydraulic Uncoiler/ Leveling Machine/ Feeding Machine/ Hydraulic Punching Device/ Roll Forming Machine/ Forming Cutting Device/ Plc Control Box

MULTI-FUNCTION AUTO PUNCHING MACHINE (3 SIDE PUNCHING)

* Suitable Profile: H-Bean, Angle Beam, C-Channel, Flat Bar & Steel Pipe

* Length Range : 1M-6M

* Size Range: 40-120mm (Width)

* Punching Hole Range: φ25-75mm

* Control Box: 1set PLC system can setting pitch, quantity.

* Auto feeding system with fixture.

* Uper punching device: 100ton punching force with die.

* Two side punching device: 60tons punching force with die.

HORIZONTAL TYPE CIRCULAR WELDING MACHINE (2 GUN) PROP AND CAP

* Use fix jig, 2 gun auto spot welding than continuous circular welding

* With manual/auto switch operation

* With spot welding manual setting

* With continuous welding time overlap control

* Connection CO2 welding machine together working

* Can one gun or two gun welding choice

* Front clamping jig can easily and fast clamping and position

* Base jig match with air cylinder eject the production, pressure equal, easily operation can adjust according table length.

* Welding gun base can adjust up and down, left and right angle, stroke 50mm

* Front and rear base same time rotation be sure welding equal.

* Control Type: PLC with HMI easy operation and maintance.

GRATING BOARD PLANT

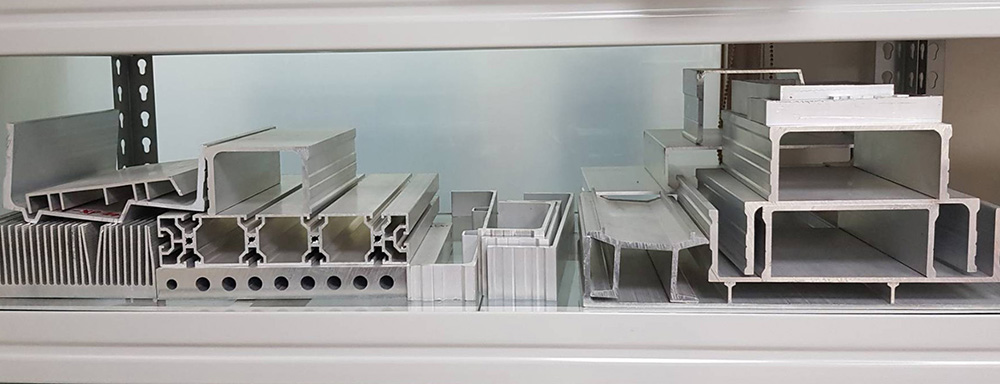

COPPER & ALUMINUM BUSBAR COMPLETE PLANT

TRANSFORMER RADIATOR PANEL

AUTOMATIC TRANSFORMER RADIATOR PANELS PRODUCTION LINE

* Material Width: 520 mm, 380 mm

* Material Thickness: 1.0 mm

* Speed: 12 M/min

Contents:a. Automatic Fin Roll Forming Machine

b. Spot Welding Machine

c. Automatic Seam Welder Machine

d. Leveling & Trimming Set

e. Steel Pipe Punching Machine

f. In Line Integration

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

Transformer Panel Line02

Transformer Panel Line04

Transformer Panel Line05

Transformer Panel Line06

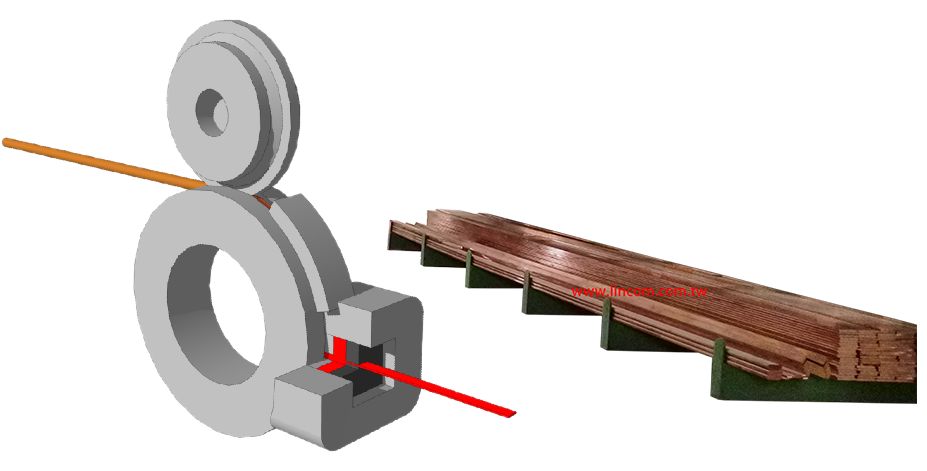

TRANSFORMER COPPER FOIL RETREATED MACHINE

* This Transformer Copper Core Retreated Machine it is special design for Transformer Copper Retreated Purpose.

Copper Retreated01

Copper Retreated02

Copper Retreated03

Copper Retreated04

※Remarks: For details please contact us.