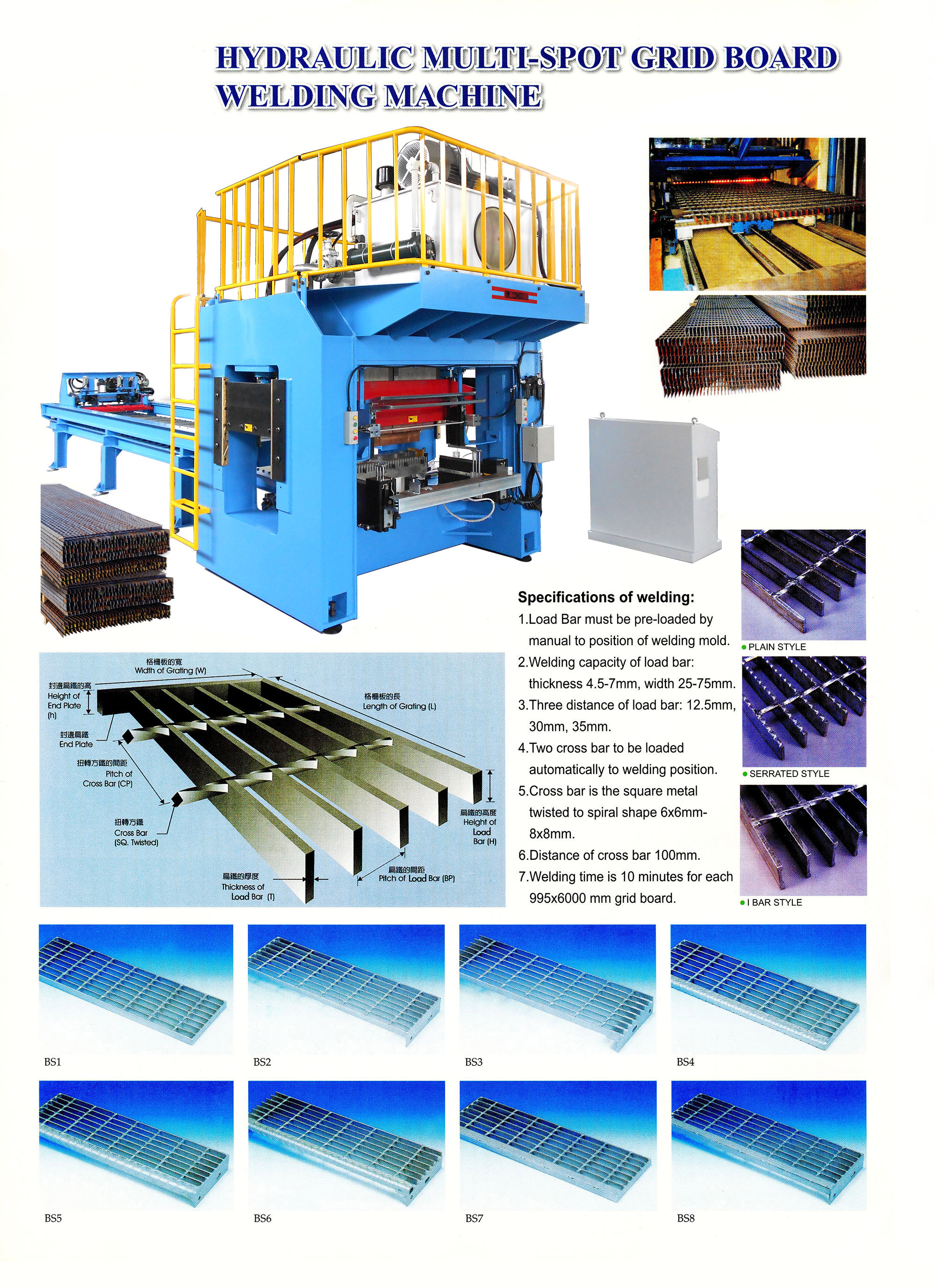

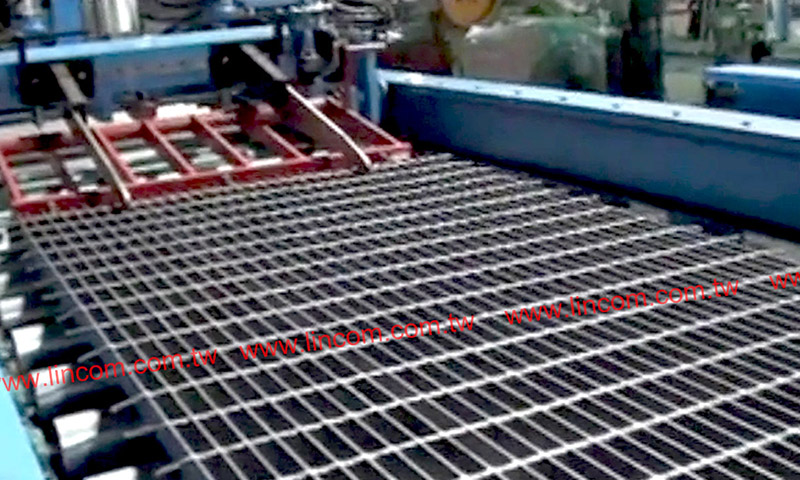

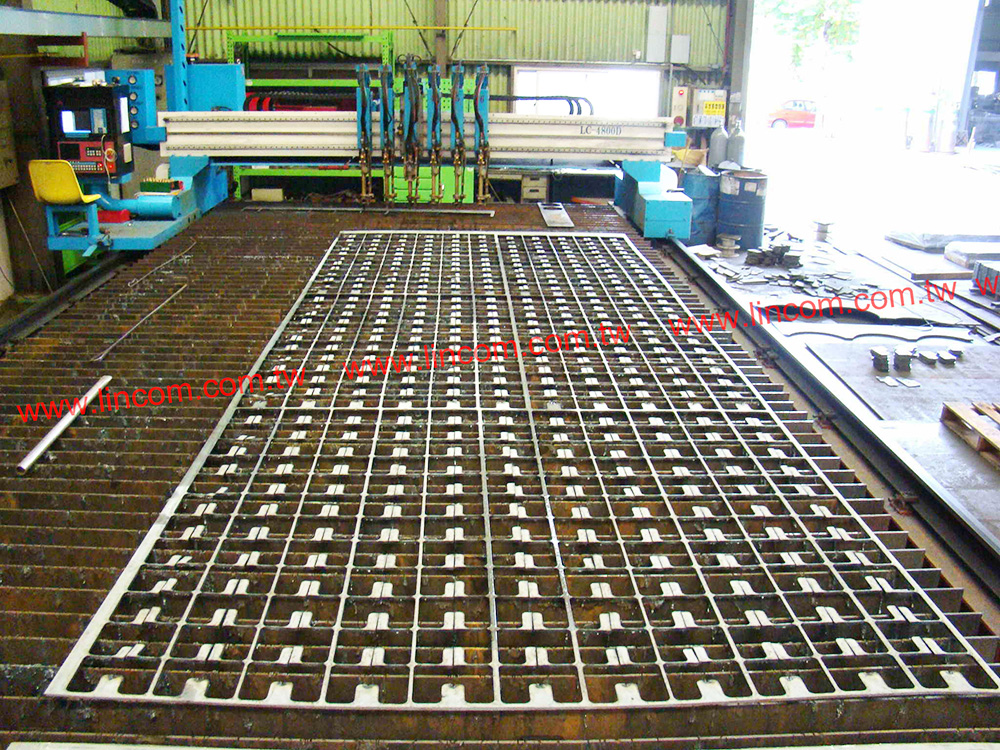

GRATING BOARD WELDING, WITH SUPER INVERTER

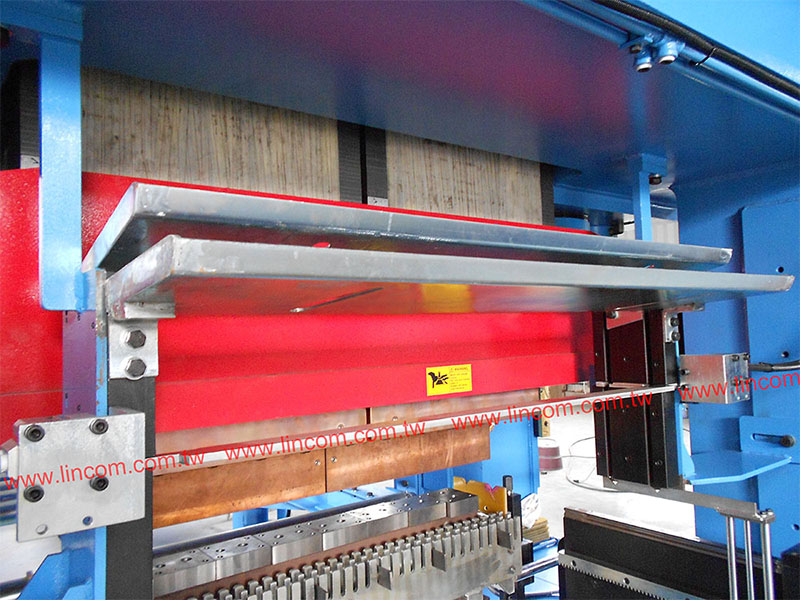

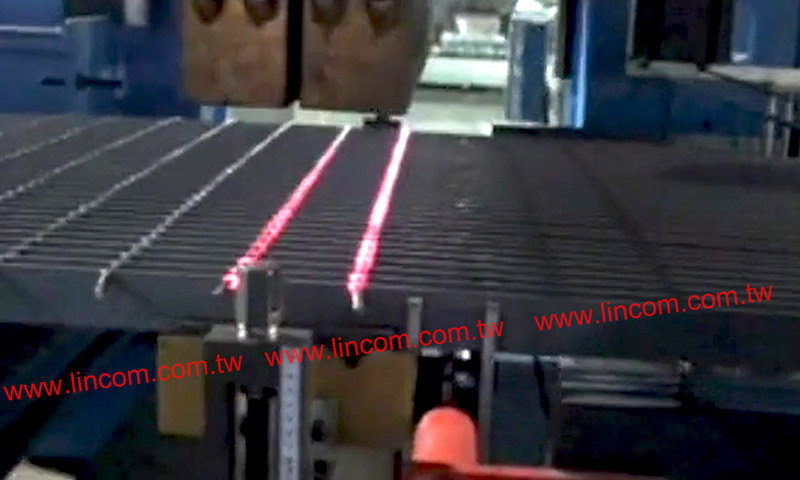

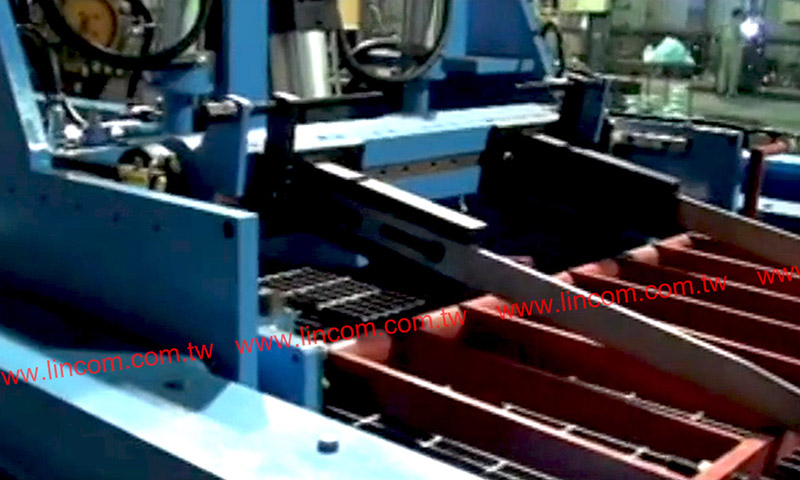

* Manual preload Load Bars to welding position when 2 Cross Bar auto-load to welding position. One time welding two Cross Bars, welding Speed is 2-3 seconds per time as per workpiece size.

* Grill Board Dimension: L6000 x W1000 mm

* Speed: 6 pcs/ hr, for board size L6000 x W1000 mm

* Size of Load Bar: 20 x 3 - 75 x 6 mm; Distance of Load Bar: 30 & 40 mm

* Size of Cross Bar: 6 x 6 - 8 x 8 mm (twisted square); Distance of Cross Bar: 100 mm

Contents:Flat Rack, Main Welding Machine, NC Material Pulling, Super Inverter

* Welding Capacity: 800KVA - A.C. Super Inverter x 3 sets

* Power Consumption Volume: 800-1000 amp (usage rate of welding is 50%)

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

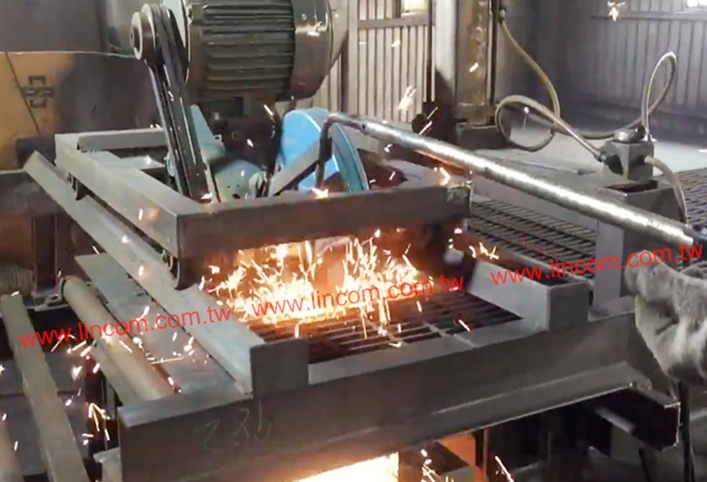

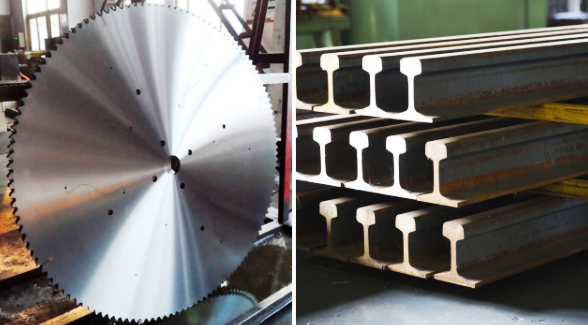

NC CIRCULAR SAW CUTTING MACHINE FOR GRATING BOARD (Servo Type)

| * Feeding Type | By Servo Feeding |

| * Grating Board Size | 1.2M(W) x 6M(L) |

| * Bearing Bar Max. | 120mm(H) x 5mm(T) |

| * Front Feeding Rack | 4M(L) x 1.2M(W) |

| * Rear Outlet Rack | 2M(L) x 1.2M(W) |

| * Motor | 5HP/4P |

* Material: Hot Rolled Steel, Cold Rolled Steel

* Oil And Water Dual Purpose, Cooling And Lubrication.

* Stepless Speed Change of Sawing Speed, Installation of Frequency Converter.

* After Sawing Is Completed, Pull The Material On Both Sides to Prevent The Knife from Clamping.

* The Control Box Adopts A Suspension Method for Easy Operation.

* Install Infrared Rays to Facilitate Marking

* The Rear Clamp Adopts Two-way Pressure to Prevent Dragging

* Full-stroke Cylinders for Front And Rear Press Systems

* Servo Motor Feeding System

Contents:Feeding Table, Main Cutting Machine, Runout Table, Control Box

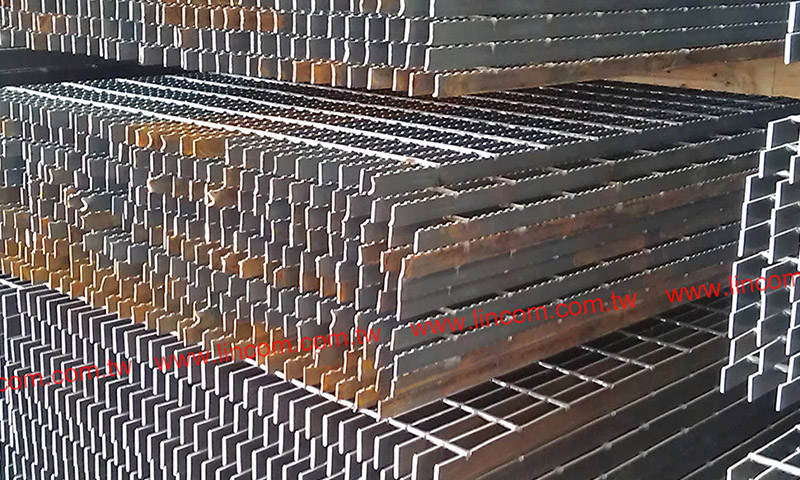

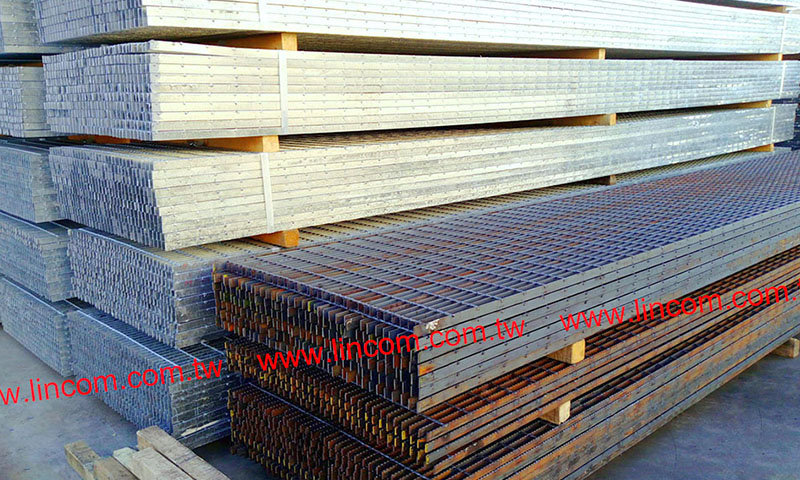

01.jpg)

02.jpg)

03.jpg)

※Remark: We can accept customer's special requirements.

NC CIRCULAR SAW CUTTING MACHINE FOR GRATING BOARD (Hyd. Type)

| * Feeding Type | Hydraulic Type |

| * Grating Board Size | 1.2M(W) x 6M(L) |

| * Bearing Bar Max. | 100mm(H) x 5mm(T) |

| * Front Feeding Rack | 4M(L) x 1M(W) |

| * Rear Outlet Rack | 2M(L) x 1M(W) |

| * Motor | 5HP/4P |

* Material: Hot Rolled Steel, Cold Rolled Steel

* Oil And Water Dual Purpose, Cooling And Lubrication.

* Stepless Speed Change of Sawing Speed, Installation of Frequency Converter.

* After Sawing Is Completed, Pull The Material On Both Sides to Prevent The Knife from Clamping

* The Control Box Adopts A Suspension Method for Easy Operation.

* Install Infrared Rays to Facilitate Marking

* The Rear Clamp Adopts Two-way Pressure to Prevent Dragging

* Full-stroke Cylinders for Front And Rear Press Systems

* Servo Motor Feeding System

Contents:Feeding Table, Main Cutting Machine, Runout Table, Control Box

※Remark: We can accept customer's special requirements.

GRATING BOARD MANUAL CUTTING MACHINE

* With 5 hp Motor

* Attach Front & Rear Plain Rack 6 x 1.2 M for each.

※Remark: For details please contact us.

※Remark: For details please contact us.

* Saw Blade Diameter: 65-450 mm

* Thickness of Saw Blade: Under 8 mm

* Sharpening Speed: 80-160 teeth per min

* Cutting Angle: 0-30 degree

* Diameter of Grinding Wheel: dia. 70-150 mm

* Grinding Wheel Speed: 50 hz/ 3800 rpm; 60 hz/ 4500 rpm

※Customers specific requirement are Welcome!

►More Related...

MEDIUM COIL SLITTING MACHINE

* Uncoiler & Recoiler Loading Capacity: Max. 10 tons

* Material: Hot Rolled Steel, Cold Rolled Steel

* Thickness: 0.6 - 6.0 mm

* Coil Width: 50 - 650 mm

* Slitting Speed: 60 M/min

Contents:Coil Cart, Uncoiler, Pressing & Feeding Inlet Device, Flex-Extend Passing Table, Straightener, Hydraulic Shearing Machine, Slitter With 2 Attached Hydraulic Shaft Screw Lock, Sheet Passing Table & Scrap Winder, Tension Pad, Recoiler, Strip Coil Cart, Hydrualic Power System, Motor, Main Operation Manual, Sub Operation Manual.

* Thickness: 2.0-6.0 mm

* Coil Width: 25-150 mm

* Max. Cutting Width: 150 mm

* Cutting Length: 4-6 M

* Length Tolerance: +/- 2 mm

* Uncoiler: Max. 2.5 Tons

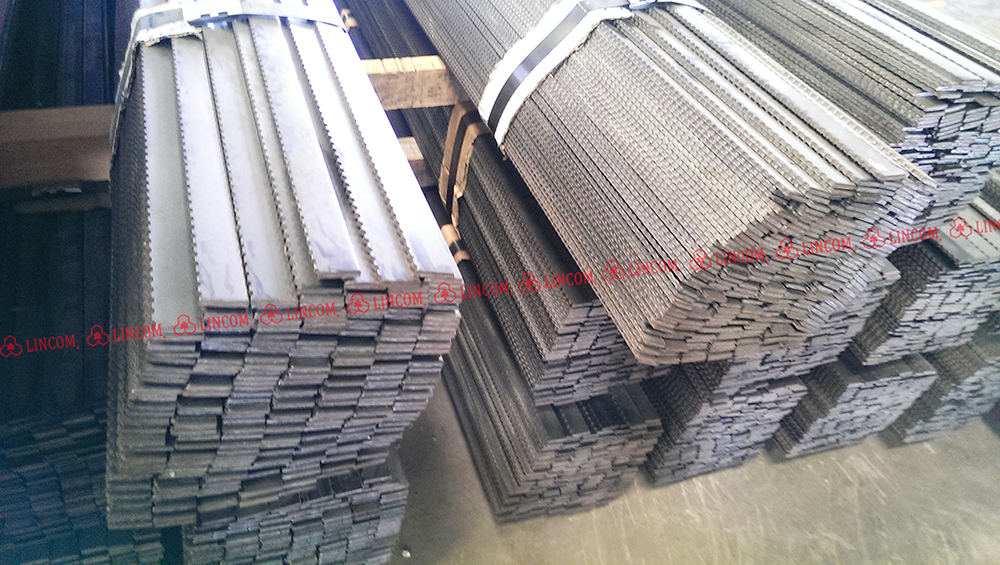

※Customers specific requirement are Welcome!AUTOMATIC FLAT BAR SERRATION & CUTTING MACHINE

* Material: Mild Steel

* Size: W 20-70 mm/ L 2.1 M/ T 2-5 mm

* Serration Speed: 2 pcs/min, counting base on 6M length

Contents:3-In-1 Uncoil + Infeed + Straighten Machine, Hydraulic Press With Serration Mold & Female Mold For Thickness 5mm, Hydraulic Cutting Device With Mold,Control Box, Hydraulic System Box, Runout Take Out Rack, Female Mold For Each Thickness of 3 & 4mm.

※Remark: We can accept customer's special requirements.

-recoil/strip-coils.jpg)

-recoil/slitting-machine-for-serrated-flat-bar.jpg)

* Material: Mild Steel

* Type: Serration By Slitting Type

* Steel Plate Thickness: 3-6 mm

* Steel Plate Feeding Width: 50-250 mm

Contents:Hydraulic Uncoiler, Straightening Device, Cutting Device, Runout Table, Recoiler, Control Box.

※Remark: For details please contact us.

* Inlet Wire: 8.5 mm Low Carbon Steel Wire;

* Finished Wire: 6 mm Tetragon

* Speed: 30 M/min

* Surface hardness treatment with tungsten carbide alloy for wire drum.

* Shutdown device is available after end wire passes the die.

* Emergency stop can be made upon wire breaking.

※Remark: For details please contact us.

* Material: Square Coil 6x6 & 8x8 mm

* Uncoiler Capacity: Max. 1500 kg

* Speed: 20 - 25 M/min

* Feeding Roller Material: SKD11 with HRC60 surface hardening treatment

* Twisting & Straightening Roller: Cast Iron 30 pcs, Tungson Carbide 6 pcs, in total 36 pcs

* Cutting Device: 3hp motor attached 2 sets of cutting die, use linear side moving when cutting.

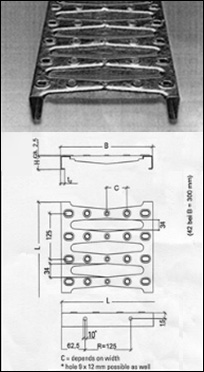

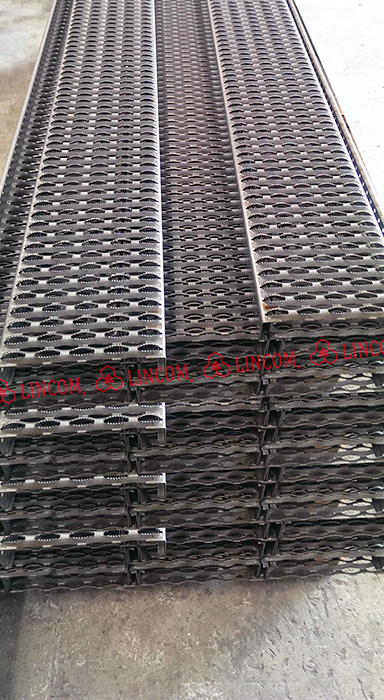

※Remark: We can accept customer's special requirements.PERFORATED METAL PLANKS (GRATING)

PERFORATED METAL PLANK AUTO ROLL FORMING MACHINE

* Material: GI, SUS, AL, Pre-painted Steel

* Thickness: 2 - 2.5 mm

* Production Speed: 6 M/min with punching hole

Contents:2-IN-1 Uncoiler & Leveling Machine, Hydraulic Punching Press, Roll Forming Machine, Form Cutting Device, Hydraulic System, Control Box, Runout Table.

※Remark: We can accept customer's special requirements.

STEEL PLATE, PIPE & H-BEAM CUTTING AND DRILLING MACHINES

CNC FLAME / PLASMA CUTTING MACHINE

Our Multi-functional CNC Plasma / Gas Cutting Machine can do drilling and tapping in one machine, it combines plate cutting and pipe cutting functions together, which includes bevel head and drilling head. When drilling, the spindle clamps the gantry, and the gantry clamps the tracks to ensure the machine remains stable when drilling.

| MODEL | LC MODEL... SERIES RANGE |

| speed | 9000;12000;18000;24000(mm/min) |

| plasma cutting speed | 30~9000mm/min |

| flame cutting speed | 30~1500mm/min |

| positioning accuracy | ±0.2mm/10m |

| repeative accuracy | ±0.1mm |

| track width | 2000;3000;4000;5000;6000;7000;9000;12000 |

| cutting width | 1550;2500;3200;4200;5100;6100;8100;11000 |

| over all width | track width+750mm |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

CNC PLASMA / GAS PLATE & PIPE CUTTING MACHINE

Our L2C Model CNC Plate and Pipe Cutting Machine is a 2-in-1 combination of cutting plate and pipe beams. This one machine can save at least 50% of the cost of two separate machines. Customers can select bevel head device to upgrade for plate and pipe bevel cutting.

| MODEL | L2C MODEL... SERIES RANGE | |

| Track Width (rail center to rail center, mm) |

3000, 3500, 4000, ... 12000 | |

| Effective Cutting Width (mm) | 2200, 2700, 3200, ... 10000 | |

| Rail Length (M) | 6, 9, 12,15... Customized to the customer's requirements. No limits. Each rail section is 3M. |

|

| Effective Working Length (M) | 3, 6, 9, 12,.... (Rail Length - 2.5M = Working Length) | |

| Positioning Speed | 18000 mm/min | |

| Positioning Accuracy | 0.1 mm | |

| Repetitive Accuracy | 0.1 mm | |

| Z-Axis (vertical) | Round Pipe 300 mm 500 mm 800 mm 1000 mm |

With Square Pipe (option) 150x150 mm 300x300 mm 400x400 mm 400x400 mm |

| Pipe Length | 6 m, 12 m | |

| Optional Add-On | Bevel Cutting | |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

CNC PLATE CUTTING WITH DRILLING AND BEVEL MACHINE

This machine is a 2-in-1 combination of plate cutting and drilling in one machine, which can save at least 50% of the cost for two separate machines. Customers can select bevel head device in our optional for plate bevel cutting and drilling.

| MODEL | LCD2 MODEL... SERIES RANGE |

| Track Width (rail center to rail center, mm) | 3000, 3500, 4000, ... 12000 |

| Effective Cutting Width (mm) | 1700, 2200, 2700, ... 10000 |

| Rail Length (M) | 6, 9, 12,15... Customized to the customer's requirements. No limits. Each rail section is 3M. |

| Effective Working Length (M) | 3, 6, 9, 12,.... (Rail Length - 2.5M = Working Length) |

| Positioning Speed | 18000 mm/min |

| Positioning Accuracy | 0.1 mm |

| Repetitive Accuracy | 0.1 mm |

| Option | Bevel Cutting |

| Drilling | High-Speed Drilling Spindle |

| Max Drilling Diameter | 32mm, 50mm |

| Max Drilling Thickness | 50mm |

| RPM | 3000 |

| Spindle Taper | BT40 |

| Cooling | Outside Cooling |

| Optional Add-On | Tapping Function |

| Optional Add-On | Auto tool changer: 10 tools |

| ※Remarks: | 1.Right of modification reserved. 2.Above are our standard model, for special requirements are welcome! |

CNC NORMAL SPEED TABLE TYPE PLATE DRILLING MACHINE

This is our standard model for Plate drilling machine, using hydraulic to drill. Spindle's up-down movement it is by hydraulic. Maximum rpm 600. Hole diameter has 2 types, 32mm or 50mm. Max. thickness is 100mm. This model is specialized steel structure application.

| Model | LPDH 1020 | LPDH 1635 | LPDH 2040 |

| Working Area | 1000 x 2000 | 1600 x 3500 | 2000 x 4000 |

| Drilling Max Thickness | 100 mm(stackable) | 100 mm(stackable) | 100 mm(stackable) |

| Drilling Hole Diameter (mm) | 14-50 | 14-50 | 14-50 |

| Variable RPM | 100-600 rpm | 100-600 rpm | 100-600 rpm |

| Motor Horsepower | 7.5 HP | 7.5 HP | 7.5 HP |

| Number of Spindles (sets) | 1 | 1or2 | 1or2 |

| Spindle Taper | MT4 | MT4 | MT4 |

| X-Axis | Ball Screw | Ball Screw | Ball Screw |

| Y-Axis (rail) | Ball Screen or Rack & Pinion | Ball Screen or Rack & Pinion | Ball Screen or Rack & Pinion |

| Z-Axis (vertical) | Hydraulic | Hydraulic | Hydraulic |

| Chip Conveyor | 1 | 1 | 1 |

| Positioning Speed | 9000 mm/min | 9000 mm/min | 9000 mm/min |

| Positioning Accuracy | ±0.03 mm (ball screw ) or ±0.1 mm (rack and pinion) | ||

| Cooling | Outside Cooling | ||

| ※Remarks: | 1.Right of modification reserved. 2.Above are our standard model, for special requirements are welcome! |

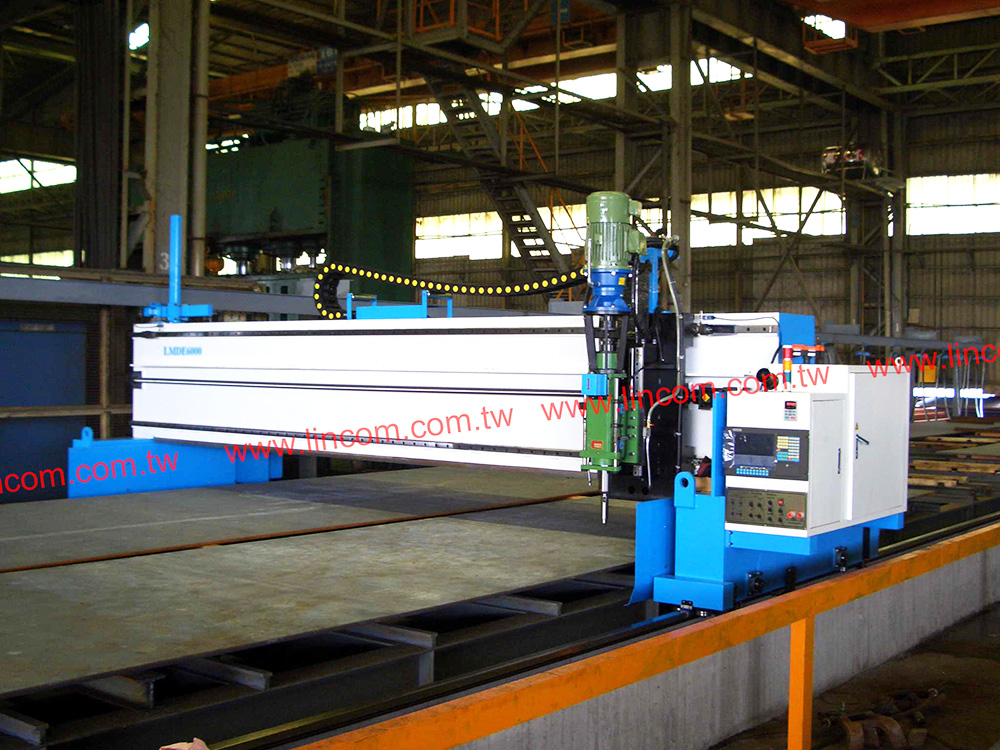

CNC HIGH SPEED EXTENDABLE TYPE PLATE DRILLING MACHINE

This Extendable Type of Plate Drilling Machine is for larger sized and one time multiple plates drilling.

| MODEL | LMDE MODEL... SERIES RANGE |

| Track Width (mm --rail center to rail center) | 3000, 3500, 4000, ... 8000 |

| Effective Working Width (mm) | 2000, 2500, 3000, ... 7000 |

| Rail Length (M) | 6, 9, 12, 15... No limits. Each rail section is 3M |

| Effective Working Length (M) | 3, 6, 9, 12,... (Rail Length - 3M = Working Length) |

| Drilling Max Thickness | 100 mm |

| Drilling Hole Diameter | 50-100mm |

| Variable RPM | 100-3000 RPM |

| Number of Spindles (sets) | 1 or 2 |

| Spindle Taper | BT 40, BT 50 |

| Motor HP | 30 HP, 40 HP |

| X-Axis | Ball Screw |

| Y-Axis | Rack & Pinion |

| Z-Axis (up/down) | AC Servo Motor |

| Positioning Speed | 12000 mm/min |

| Positioning Accuracy | 0.1 mm |

| Repetitive Accuracy | 0.1 mm |

| Cooling | Outside Cooling or Cooling Through Spindle (CTS) |

| ※Remarks: | 1.Right of modification reserved. 2.Above are our standard model, for special requirements are welcome! |

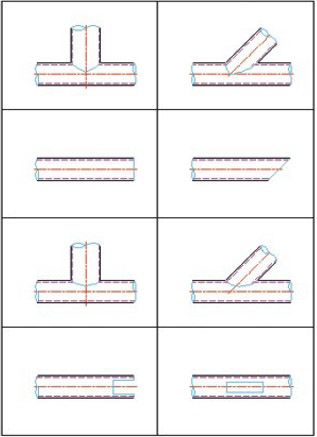

CNC ROUND / RECTANGLE PIPE CUTTING MACHINE

This model of Round/Rectangle Pipe Cutting Machine can straight cut and bevel cut pipe in one machine. Customers can either choose light model or heavy-duty model base on their workpiece requirement. Send us your production requirements to have our specialist to choose the right model that meets your need.

* Application: Steel Structure, Shipbuilding, Chemical Work Industries, etc.

* Applicable for Round/Square/Rectangle shape of pipes cutting.

* Customers can upgrade bevel cutting function.

| MODEL | LPC MODEL... SERIES RANGE | |

| Pipe Diameter(mm) | Round Pipe | with Square Pipe (optional) |

| 300 500 800 1000 |

150x150 300x300 400x400 400x400 |

|

| Cutting Length (mm) | 6000, 12000 | |

| Round Pipe Support (sets) | 2 (pipe length=6M) or 4 (pipe length = 12M) | |

| Square Pipe Support (sets) | 2 | |

| Positioning Speed | 18000 mm/min | |

| Positioning Accuracy | 0.1 mm | |

| Repetitive Accuracy | 0.1 mm | |

| Option | Bevel Cutting | |

| ※Remarks: | 1.Above are Standard model, We accept customers specific requirements. 2.Right of modification reserved. |

PORTABLE CNC PIPE CUTTING MACHINE

This Portable Pipe Cutting Machines is applicable to operate in any sites, including construction sites or outdoors, for pipe cutting and profiling.

This machine is equipped with CNC numeric control interface, by 2 axis servo transmission. Applicable for installing Plasma/ Flame for circular pipe drilling and pipe end cutting. Axis 1 is rotation axis, it fixes circular workpiece with a gripper jaw. Axis 2 is for moving the workpiece. Customer can choose to upgrade the machine by choosing to add the optional Axis 3 for enabling the machine to straight, miter and branches cuts the pipe ends. All functions are human-machine interface controlled, easy operation. The machine is attached with disc drive and USB connector. File format is DXF, CNC or by operator manually key in.

Specification| Type Model | Workpiece Diameter (mm) | Torch Stroke (mm) | Through-Hole | Cutting Speed (mm) | |

| Min | Max | ||||

| LPPC 300 | 25 | 300 | 1000 | 150 | 3000 |

| LPPC500 | 25 | 500 | 1500 | 250 | 3000 |

| LPPC800 | 25 | 800 | 2000 | 400 | 3000 |

| ※Remarks: | 1.Above are Standard model, We accept customers specific requirements. 2.Right of modification reserved. |

CNC H-BEAM DRILLING MACHINE

This CNC H-Beam Drilling Machine has adopted robot system to push H-Beams forward for higher precision of length calculation. It can auto detect the thickness of beams and automatically withdraw when drilling tip drills through. The machine auto switches to quick feeding and drilling feeding speed when the drilling bit touches the H-Beam,and when the drilling bit withdraws, the spindle senses difference of drilling pressure. Therefore, the operator doesn't need to set parameters for each drilling, which allows a more efficient and easy operation.

| MODEL | LHD MODEL... SERIES RANGE |

| Drilling Capacity | 150x100 mm - 1800x1500mm |

| H-Beam Length | 6M, 12M, 15M, 18M |

| Number of Spindles (sets) | 3 |

| Drilling Max Hole Diameter | 32 mm, 50 mm |

| Drilling Max Thickness | 50 mm |

| Feeding Device | AC Servo Feeding Arm (Rack & Pinion) |

| Feeding Accuracy | 0.1 mm |

| Spindle Motor Power | 7.5 HP |

| Variable RPM | 100-600 RPM |

| Spindle Taper | MT4 |

| Drilling | Hydraulic |

| Positioning Accuracy | +/- 0.1 mm |

| Cooling | Outside Cooing |

| Option | Inlet and Outlet Roller Supports |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

CNC H-BEAM CUTTING COPING MACHINE

Commonly used for steel structure, the CNC H-Beam Cutting Coping Machine can be used for H-beam gas/plasma cutting torch to cut. It has an optional robot system to push H-beams forward automatically and can cut all length to several sections automatically if necessary.

| Model | LHCC 15060 | LHCC 10050 | LHCC 7035 |

| H-Beam Size H-Beam | 150x100 mm - 1500x600mm | 150x100 mm - 1000x500mm | 150 x100 mm - 700 x350 mm |

| C channel | 500 x 300mm | 500 x 250mm | 500 x 175mm |

| Angle steel Size | 300 x300mm | ||

| Length | No Limit | ||

| Cutting Length | 800mm | ||

| Number of Cutting Tool | 1 Gas Cutting Torch or 1 Plasma Cutting Torch | ||

| Capacity | Gas: 150mm; Plasma: depends | ||

| Transmission | AC Servo Motor, 5 Axis Control | ||

| Positioning Accuracy | 0.1 mm | ||

| Optional | Robot Arm Feeding System with Rail | ||

| Optional | Inlet and Outlet Roller Supports | ||

| ※Remarks: | 1.Above are Standard model, We accept customers specific requirements. 2.Right of modification reserved. |