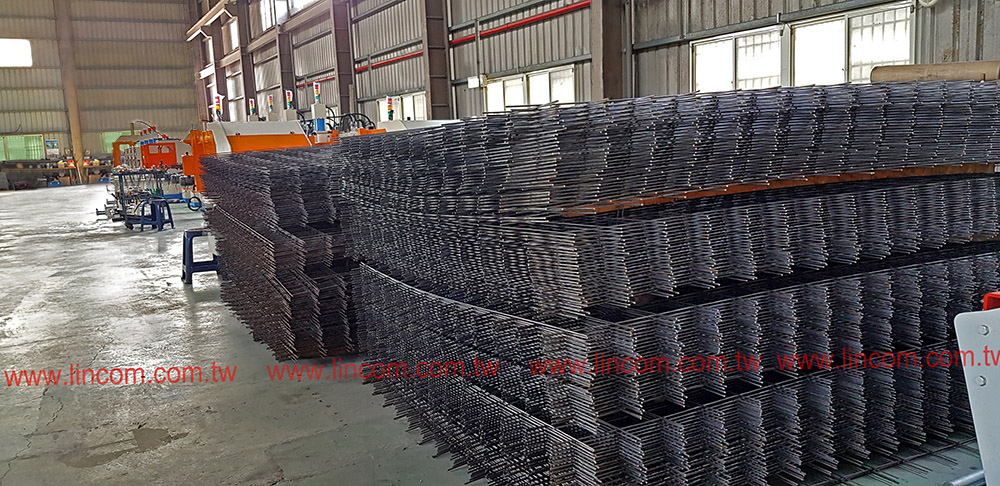

🔸 For Wire Mesh Machine... we have many different design can meet customers different requirement...

we also accept customer’s special requirement...

Coil to Coil Wire Mesh Welding Machine is designed for quick change-over, easy & fast changing of different wire mesh sizes. The Line Wire feeds from coil, and precut Cross Wire is by auto feeding. The design adopts future versatility system to merge options to meet future requirements.

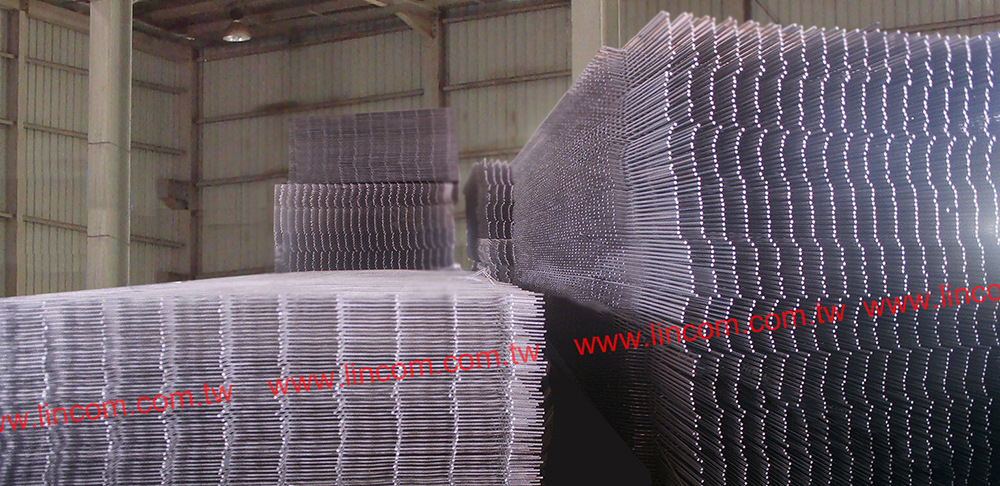

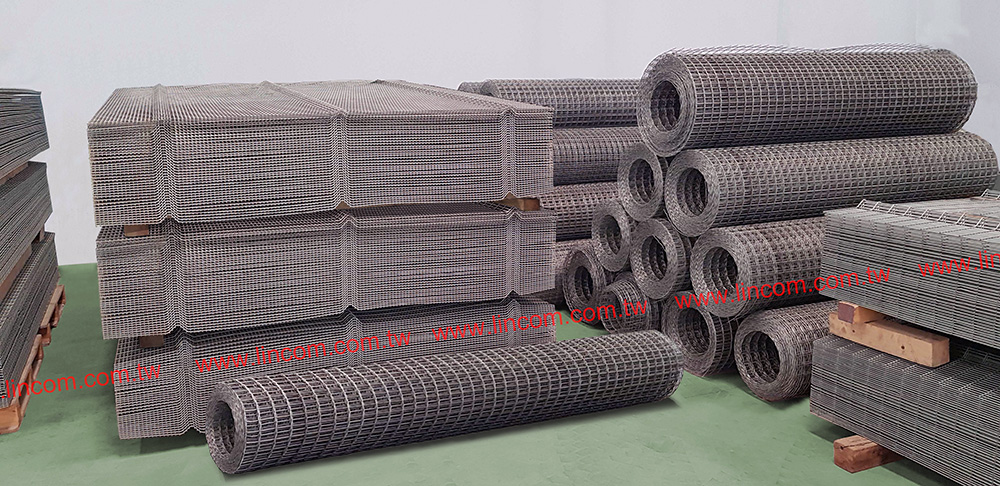

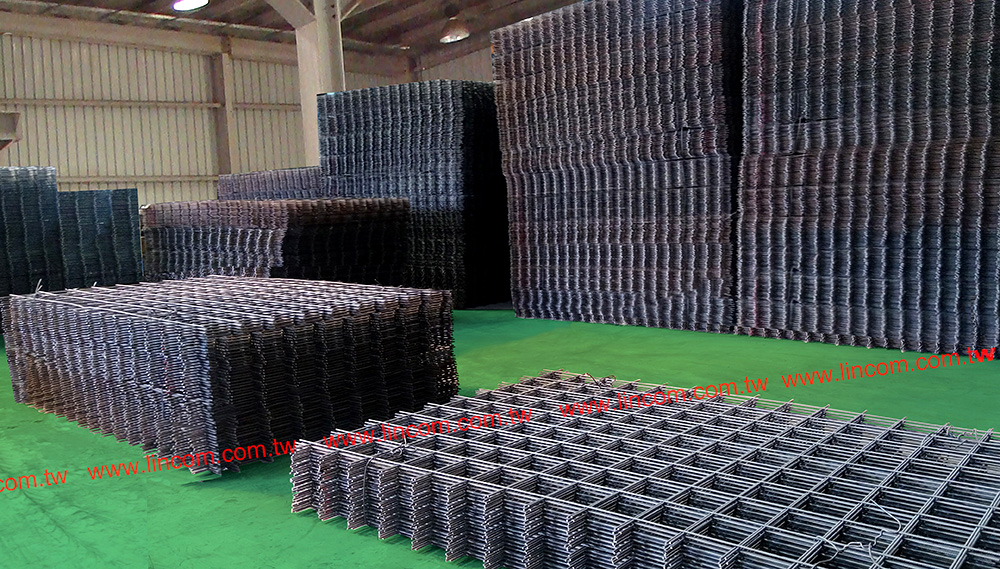

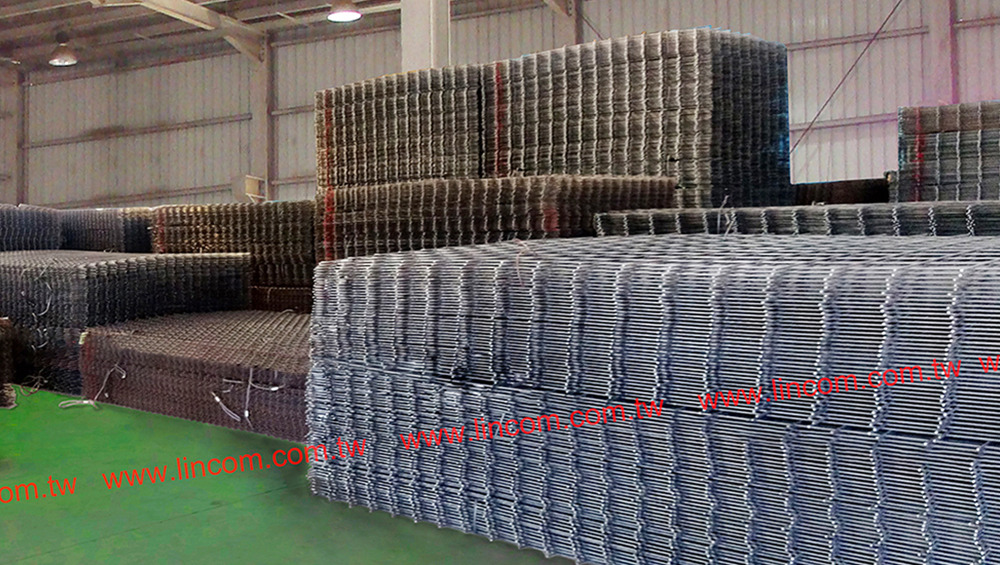

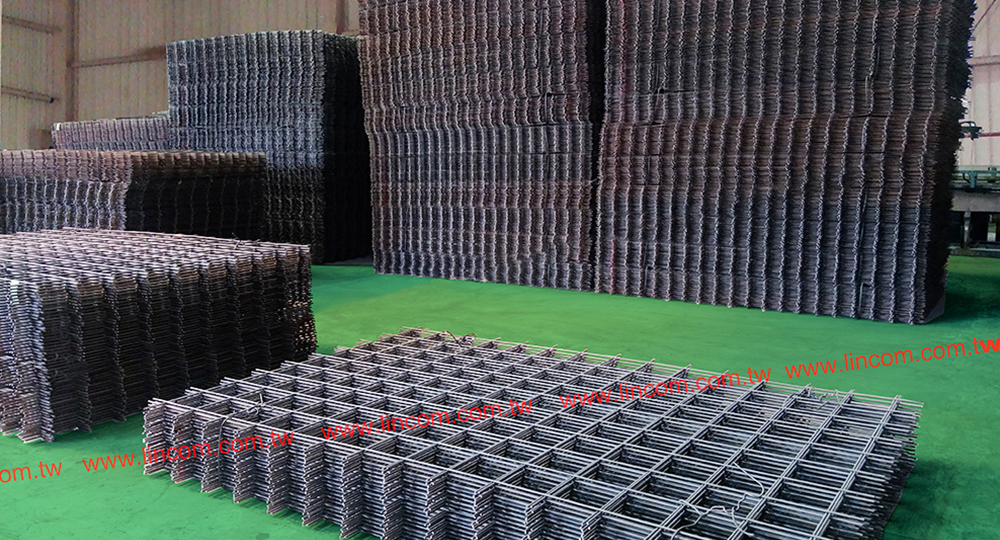

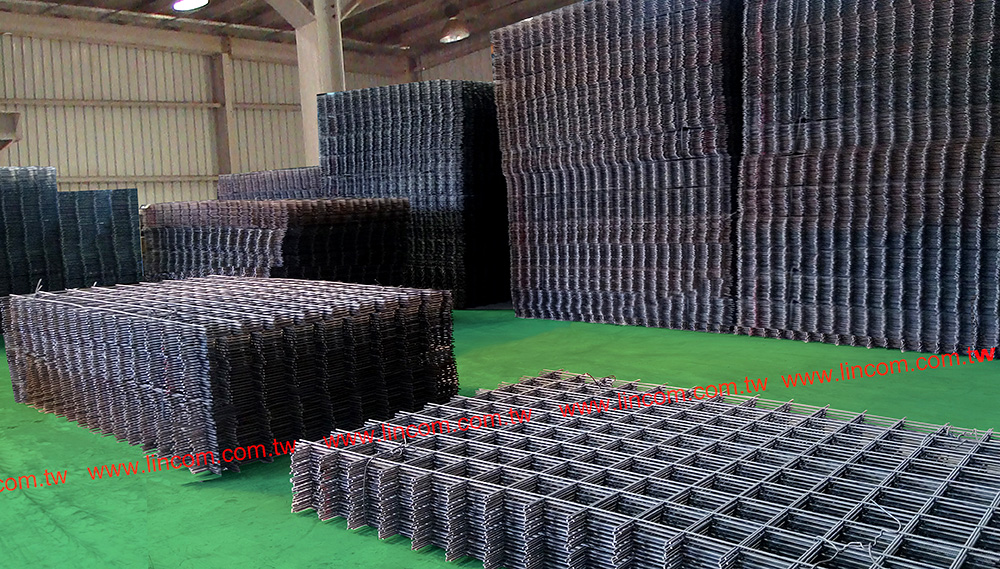

Application:Reinforced Wire Mesh, Chicken Wire Mesh, welded wire mesh fencing, fencing net, barrier fence, metal fence, galvanized weld mesh, ine mesh, fence netting, welded nets, temporary fencing, security fencing mesh, display rack, cages, etc.

Contents:- Wire Straightening Device: Two sets of the device for wire straightening.

- Wire Feeding System: Two feeding devices. One driven by converter motor for wires to wire accumulator, another is driven by servo motor for wires. To the welding machine. Both to help welding pitch precisely.

- Mesh Welding Machine: According to mesh welding pitch, machine can adjust upper cylinders, electrodes. Adjustable for each welding point and current, which are controlled by thyristorand micro-computor timer for the most perfect welding.

- Cross Wire Carriage: Precutted wires loading to carriage by crane and auto carriage for sorting, positioning and ejecting.

| Model | Mesh Length (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| LCM - 2400B | Unlimited | 1000 - 2400 | Ø 3 - 4 | ≧76.2 | ≧12.7 |

| LCM - 3000B | Unlimited | 1000 - 3000 | Ø 3 - 4 | ≧76.2 | ≧12.7 |

| LCM - 3600B | Unlimited | 1000 - 3600 | Ø 3 - 4 | ≧76.2 | ≧12.7 |

| ※Remarks: | 1.Right of modification reserved. 2.Above are our standard model, for special requirements are welcome! |

WIRE MESH MACHINE,... Coil To Coil Or Shearing

For Coil To Coil Or Shearing Wire Mesh Welding Machine, different diameter wire, the welding time and current can be easily adjusted. Its Line Wire feeding is by loading steel coil to wire feeding device via wire straightening device by driven motor, and as per required distance, pitch can be set precisely. Cross Wire feeding is by auto carriage with wire hopper for sorting, positioning and ejecting. After welding, according to required length, the welded mesh conveys to proceed at the guillotine shear or recoiler.

Application:Galvanised Weldmesh, Concrete Reinforcement, Fine Mesh, Wire Mesh Partitions, Concrete Meshes, Welded Mesh Fabric, Steel Wire Mesh, Engineered Mesh, Steel Fabric Mesh, Electrowelded Steel Wire Mesh, Fence Netting, Welded Nets, Temporary Fencing, Security Fence, Metal Fence, Concrete Forming System, Reinforcement Fabric, Shell Structure, Welded Netting, Welded Screens, Wall Structure, Reinforced Concrete Road, Retaining Wall, Protection Slope, Floor, Floor Boards, Successive Wall, Safety/ Security Enclosures, Security Barriers, Prison Mesh, Prison Security Fencing, Rigid Mesh, Prefabricated Steel Reinforcing Material, Fabricated Stainless Steel Wirework.

Contents:- Wire Straightening Device: Two sets of the device for wire straightening.

- Wire Feeding System: Two feeding devices. One driven by converter motor for wires to wire accumulator, another is driven by servo motor for wires to the welding machine. Both to help welding pitch precisely.

- Mesh Welding Machine: According to mesh welding pitch, machine can adjust upper cylinders, electrodes. Adjustable for each welding point and micro-computer timer for the most perfect welding.

- Cross Wire Carriage: Precutted wires loading to carriage by crane and auto carriage for sorting, positioning and ejecting.

- Controlling System: Adopt PLC with HMI touch screen. All system parameters are on screen.

| Model | Mesh Legnth (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| LCM - 125A | Unlimited | 1000 - 2400 | Ø 3 - 6 | 100 - 300 | ≧50 |

| LCM - 200A | Unlimited | 1000 - 2400 | Ø 6 - 12 | 100 - 300 | ≧50 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

WIRE MESH WELDING MACHINE - Coil Feed,... Up/Down Welded

Coil Feed Up/Down Welded Wire Mesh Machine is equipped with 24 group shelves of coil feeding system. The machine adjusts pitch within seconds only. The Up/Down Welding is performed in upper and lower welding by one piece welding on top and another piece welding at the bottom, so when welding completes, the finished stack is same as having turn-over device to flip over.

Application:Concrete Reinforcement, Steel Wire Mesh, Welded Mesh Fabric, Engineered Mesh, Concrete Forming System, Reinforcement Fabric Concrete Meshes, Prefabricated Steel Reinforcing Material, Fabricated Stainless Steel Wirework, Shell Structure, Wall Structure, Reinforced Concrete Road, Retaining Wall, Protection Slope, Floor, Floor Boards, Successive Wall, Steel Grating, Protective Grill, Stair Treads, Grating Trench Cover, Floor Grating, Forge-Welded Grating, Grill Floor, Metal Floor, Ribbed and Pressed Metal Mesh.

Contents:-Coil Wire Feeding Stand: Line Wire don't need to precut as the machine is equipped with 24 sets of Coil Shelves.

-Line Wire Straightening Wheel: 24 sets. Line Wire will be straightened through the straightening stand. Then be sent to the main welding machine.

-Main Double Welding Base: When welding completed, it is auto-connected with auto cutting machine.

-Automatic Cutting Machine: Equipped with 400 liter oil tank and nitrogen bottle for cutting action. The speed of the cutter is less than one second.

-Wire Mesh Conveyor

| Model | Mesh Legnth (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| LCMC - 125 | Unlimited | 1000 - 2400 | Ø 3 - 6 | 100 - 300 | ≧50 |

| LCMC - 200 | Unlimited | 1000 - 2400 | Ø 6 - 10 | 100 - 300 | ≧50 |

| LCMC - 300 | Unlimited | 1000 - 3000 | Ø 6 - 10 | 100 - 300 | ≧50 |

| ※Remarks: | 1.Right of modification reserved. 2.Above are our standard model, for special requirements are welcome! |

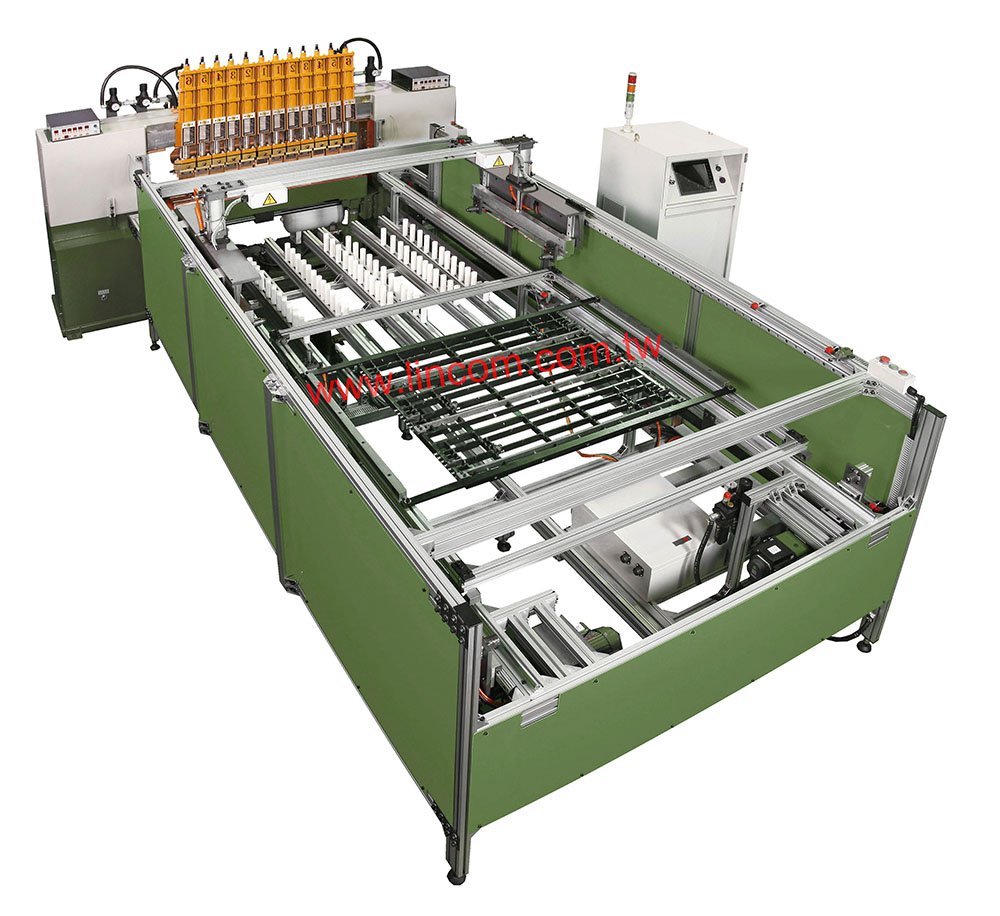

WIRE MESH WELDING MACHINE - Precut, Manual Feed,... With Turnover Device

This type of Wire Mesh Welding Machine, the Line Wire and Cross Wire are precut and Line Wire loaded manually and Cross Wire after loading into the auto feeder, the auto feeder will arrange the wire automatically, The pitch adjustment it is within seconds only. This model is ideal also for other welding purpose use besides wire mesh. The rear stage is connected with turnover device.

Application:Concrete Reinforcement, Steel Wire Mesh, Welded Mesh Fabric, Engineered Mesh, Concrete Forming Ststem, Reinforcement Fabric Concrete Meshes, Prefabricated Steel Reinforcing Material, Fabricated Stainless Steel Wirework, Shell Structure, Wall Structure, Reinforced Concrete Road, Retaining Wall, Protection Slope, Floor, Floor Boards, Successive Wall, Steel Grating, Protective Grill, Stair Treads, Grating Trench Cover, Floor Grating, Forge-Welded Grating, Grill Floor, Metal Floor, Ribbed and Pressed Metal Mesh.

Contents:a. Straight Line (Beeline) Feeding Stand

b. Transverse Line Auto Feeding Device

c. Main Welding Machine

d. Wire Mesh Carrier & Auto Stacker

e. Wire Mesh Turn-Over Device

| Model | Mesh Length (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

| LCMA - 125 | 2000 - 6000 | 1000 - 2400 | Ø 3 - 6 | 100 - 300 | ≧50 |

| LCMA - 200 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 10 | 100 - 300 | ≧50 |

| LCMA - 300 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 12 | 100 - 300 | ≧50 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

WIRE MESH WELDING MACHINE - Precut, Manual Feed,... Up/Down Welded

This model of Wire Mesh Welding Machine is designed to weld one piece on top and another piece welding at bottom, so when welding completes, the finished stack is same as having turn-over device to flip over. Line Wire is precut and by manual feed. Cross Wire is precut and after loading into the auto feeder, the auto feeder will arrange the wire automatically.

Application:Concrete Reinforcement, Steel Wire Mesh, Welded Mesh Fabric, Engineered Mesh, Concrete Forming Ststem, Reinforcement Fabric Concrete Meshes, Prefabricated Steel Reinforcing Material, Fabricated Stainless Steel Wirework, Shell Structure, Wall Structure, Reinforced Concrete Road, Retaining Wall, Protection Slope, Floor, Floor Boards, Successive Wall, Steel Grating, Protective Grill, Stair Treads, Grating Trench Cover, Floor Grating, Forge-Welded Grating, Grill Floor, Metal Floor, Ribbed and Pressed Metal Mesh.

Contents:a. Straight line (beeline) Feeding Stand

b. Transverse line Auto Feeding Device

c. Main Welding Machine (One Piece Upper Welding and second piece bottom welding function equal as Turn Over Device)

d. Wire Mesh Carrier & Auto Stacker

| Model | Mesh Length (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| LCMB - 125 | 2000 - 6000 | 1000 - 2400 | Ø 3 - 6 | 100 - 300 | ≧50 |

| LCMB - 200 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 10 | 100 - 300 | ≧50 |

| LCMB - 300 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 12 | 100 - 300 | ≧50 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

WIRE MESH WELDING MACHINE - Precut, Manual Feed

The Line Wire & Cross Wire both is precut and Line Wire by manual loading and Cross Wire after loading into the auto feeder the Feeder will arrange the wire automatically, and then to welding position.its pitch adjustment is within seconds only, and the machine rear stage is connected with a mesh auto stacker.

Application:Concrete Reinforcement, Steel Wire Mesh, Welded Mesh Fabric, Engineered Mesh, Concrete Forming Ststem, Reinforcement Fabric Concrete Meshes, Prefabricated Steel Reinforcing Material, Fabricated Stainless Steel Wirework, Shell Structure, Wall Structure, Reinforced Concrete Road, Retaining Wall, Protection Slope, Floor, Floor Boards, Successive Wall, Steel Grating, Protective Grill, Stair Treads, Grating Trench Cover, Floor Grating, Forge-Welded Grating, Grill Floor, Metal Floor, Ribbed and Pressed Metal Mesh.

Contens:a. Straight line (beeline) Feeding Stand

b. Transverse line Auto Feeding Device

c. Main Welding Machine

d. Wire Mesh Carrier & Auto Stacker

| Model | Mesh Length (mm) | Mesh Width (mm) | Wire Diameter (mm) | Line Wire Pitch (mm) | Cross Wire Pitch (mm) |

|---|---|---|---|---|---|

| LCMN - 125 | 2000 - 6000 | 1000 - 2400 | Ø 3 - 6 | 100 - 300 | ≧50 |

| LCMN - 200 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 10 | 100 - 300 | ≧50 |

| LCMN - 300 | 2000 - 6000 | 1000 - 2400 | Ø 6 - 12 | 100 - 300 | ≧50 |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

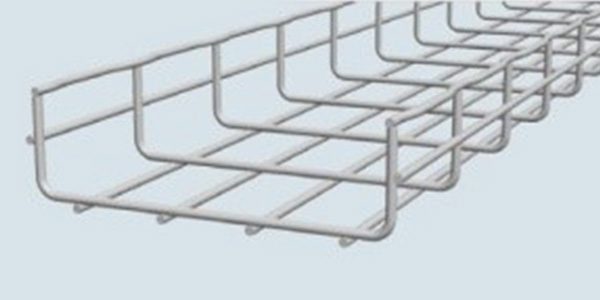

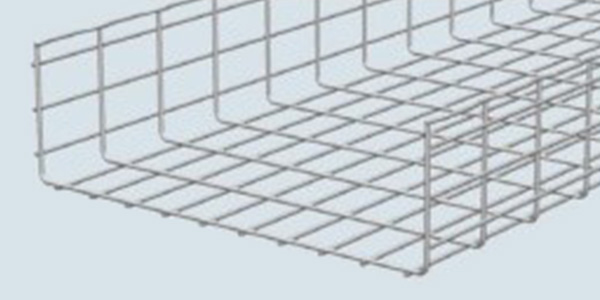

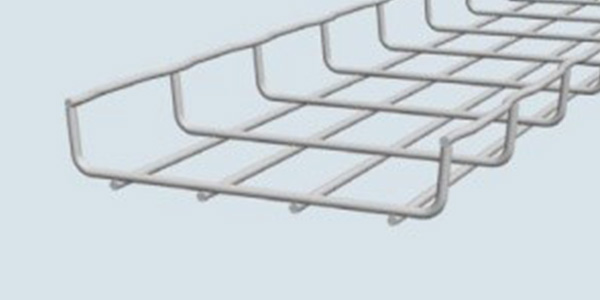

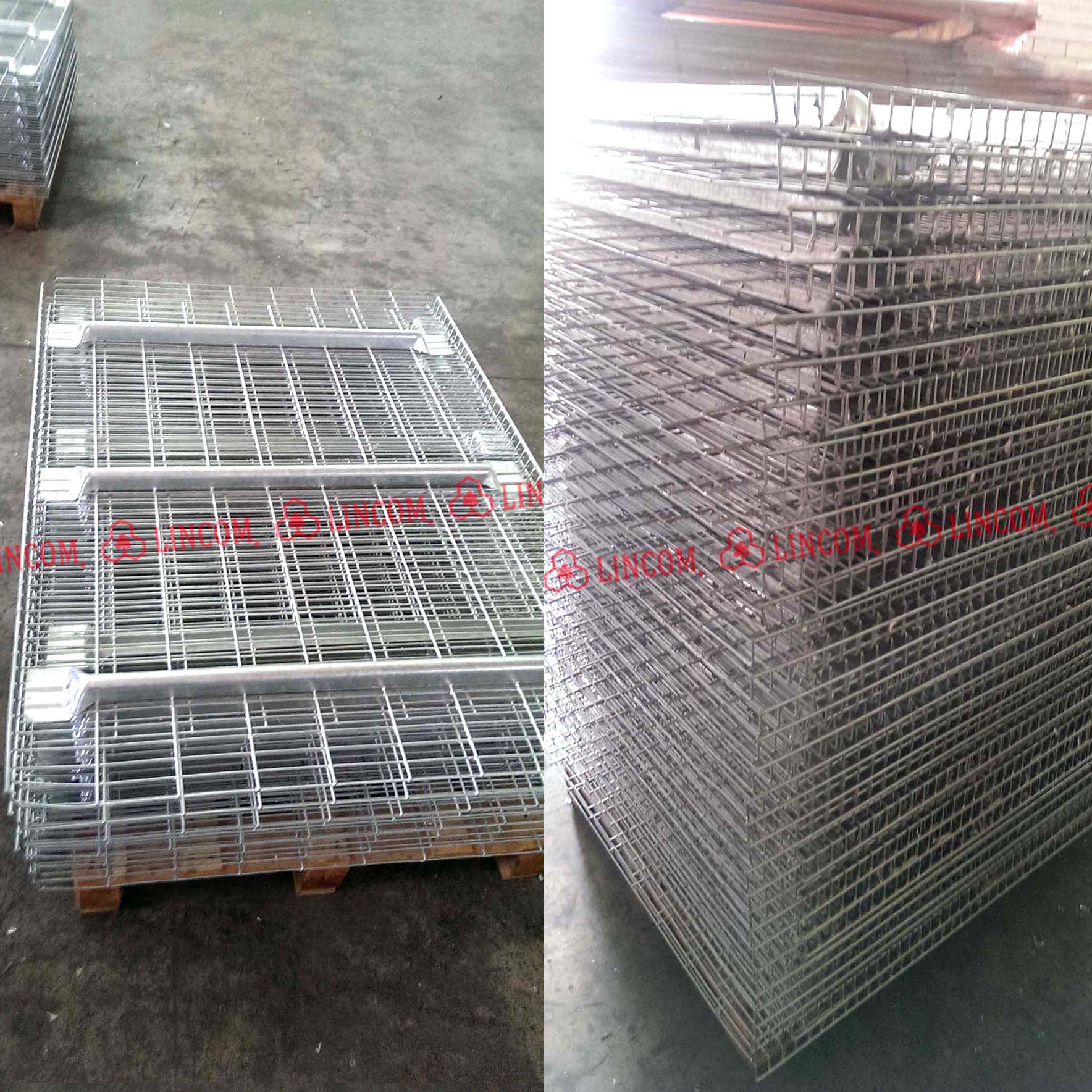

WIRE CABLE TRAY, STORAGE, WAREHOUSE, CARTS, CAGES…

WIRE BASKET TRAY content-01ION MACHINE

Wire Straighten and Cutting Machine

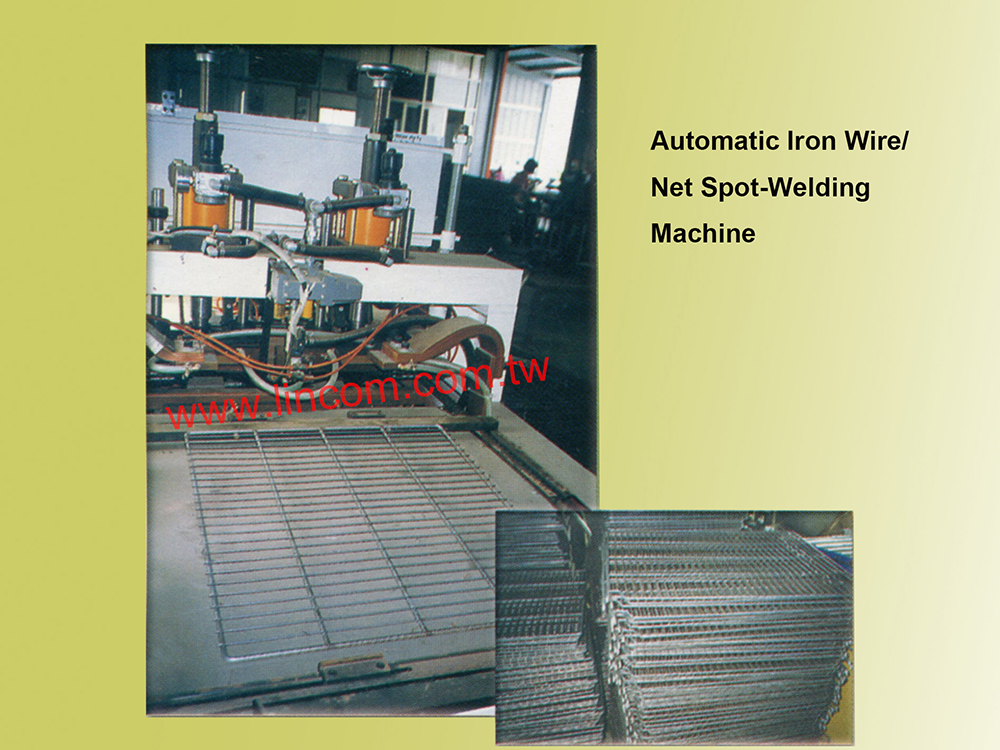

Multi-Point Pneumatic Spot Welder

* Rated Capacity: 120 KVA*2

* Applicable wire diameter: Ø3.5mm~Ø7.0mm

Basket Tray Bending Machine

* Capacity: Max. bend width: 600mm

* Tray Side High :30-150mm

* Throat Depth: 305 mm

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

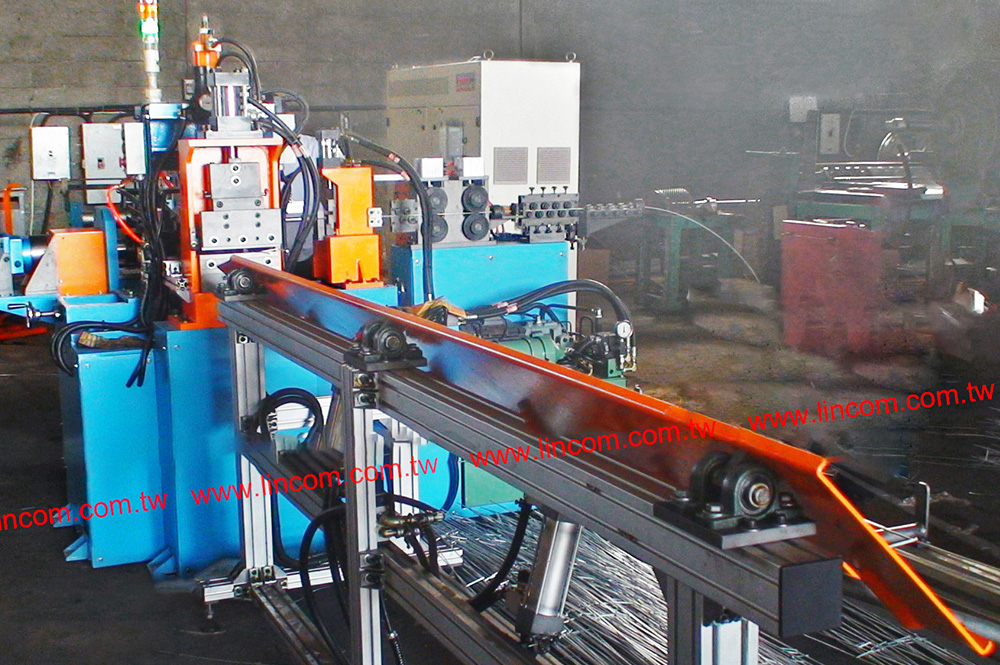

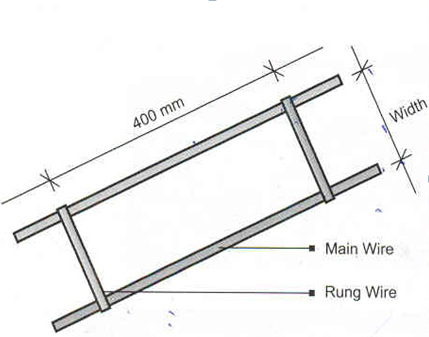

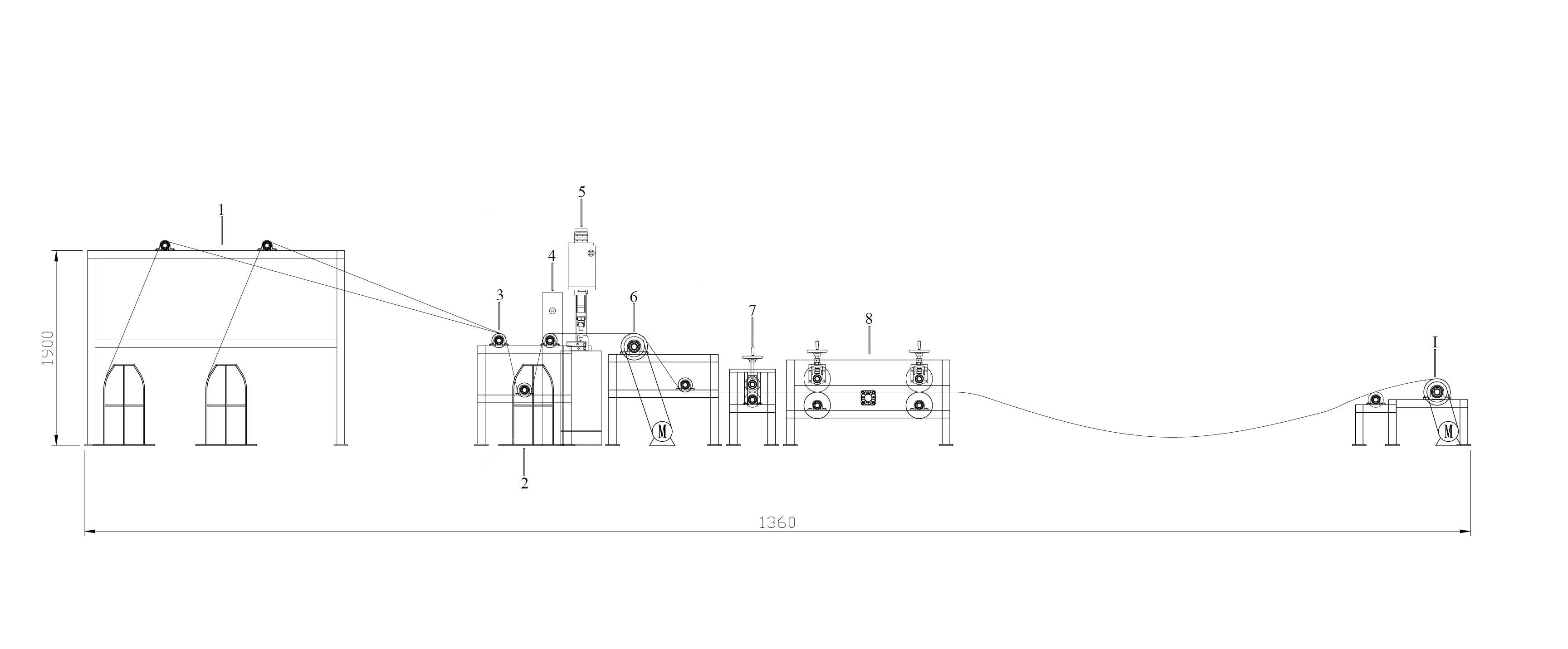

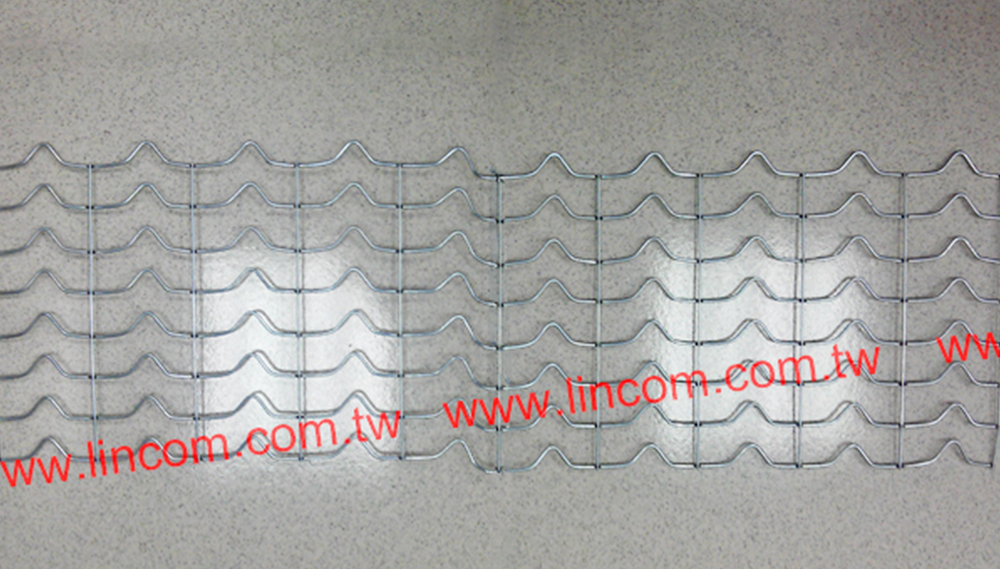

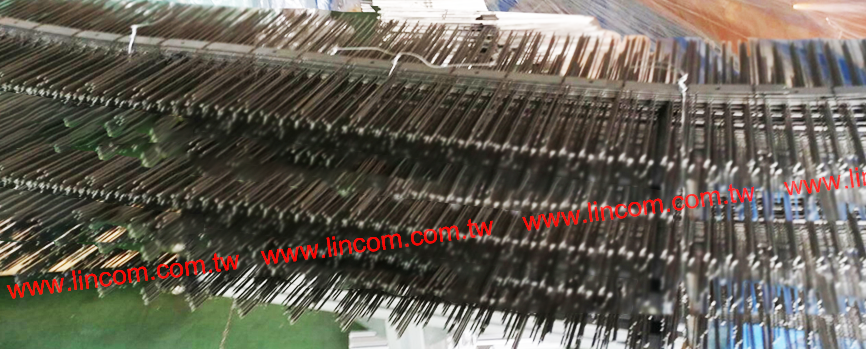

AUTO BLOCK LADDER TRUSS MAKING MACHINE

* Work Piece: Hot Dip Ribbed Wire Ø 3 - 6 mm, P 400 mm/ L 3000 mm/ H 50 - 250 adjustable

* content-01ion: 6 - 8 M/min when P400 mm

Contents:Pay Off Feeder (spool) / Wire Detecting Device & Straightening Device (for 4 line wires) / Wire Feeding Device (standard motor) / Accumulating Device / Re-straightening Device / Wire Feeding Device (servo motor) / Wire Zig-Zag Forming Device (zig-zag wire welded at top / cross wire welded at bottom) / Switch Cabinet (PLC + HMI touchscreen).

※Remark: We can accept customer's special requirements.

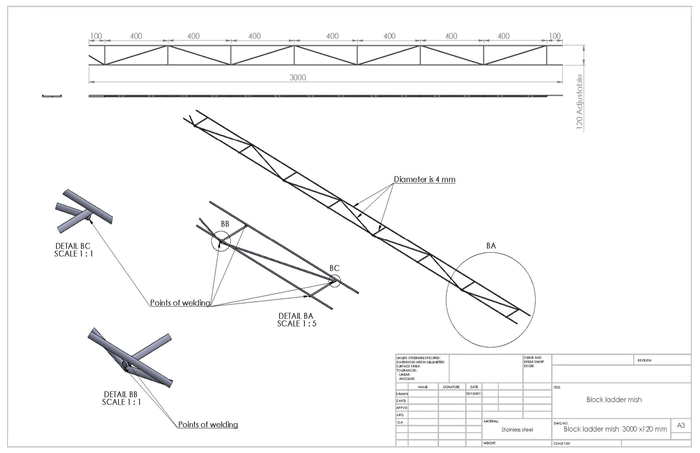

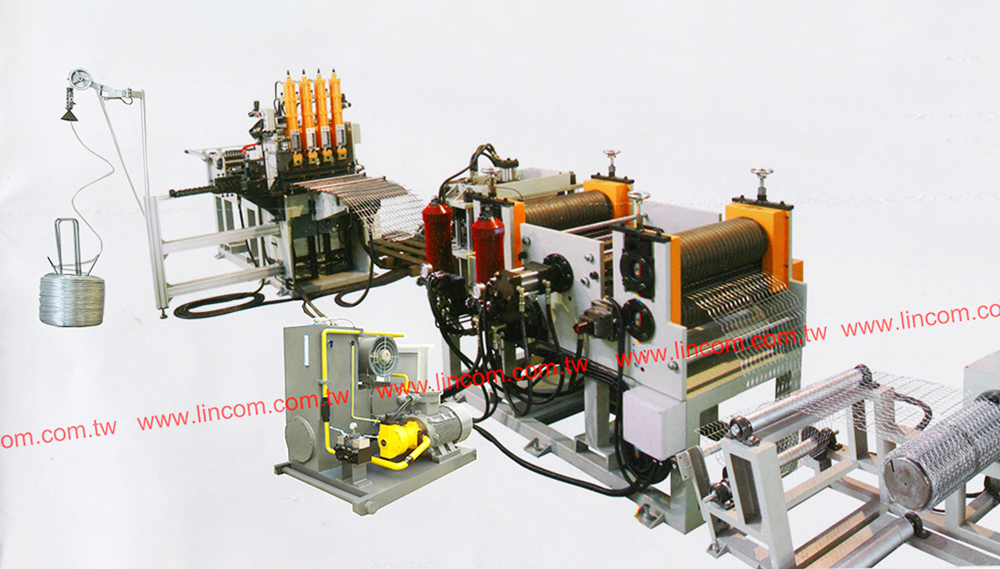

BLOCK LADDER MESH MAKING MACHINE

* Working Piece: - Material: Mild Steel, Stainless Steel - Wire Diameter: Ø 3 - 5 mm - Pitch: 375 mm - Height: 100, 150, 200, 250 mm - Length: 3000 mm - Overhang: 5 mm - content-01ion Speed: 8 - 10 M/min (counting base on wire diameter 4.0 x 3.8mm, P=375 mm).

Contents:Pay Off Feeder (spool) / Wire Accumulator Device / Wire Straightening Device / Advancing Device (servo amplifier driven, line & cross wire is servo motor driven) / Cross Wire Shearing Device (PLC + HMI touchscreen).

※Remark: We can accept customer's special requirements.

OIL PIPE REINFORCEMENT CRIMP MESH WELDING MACHINE

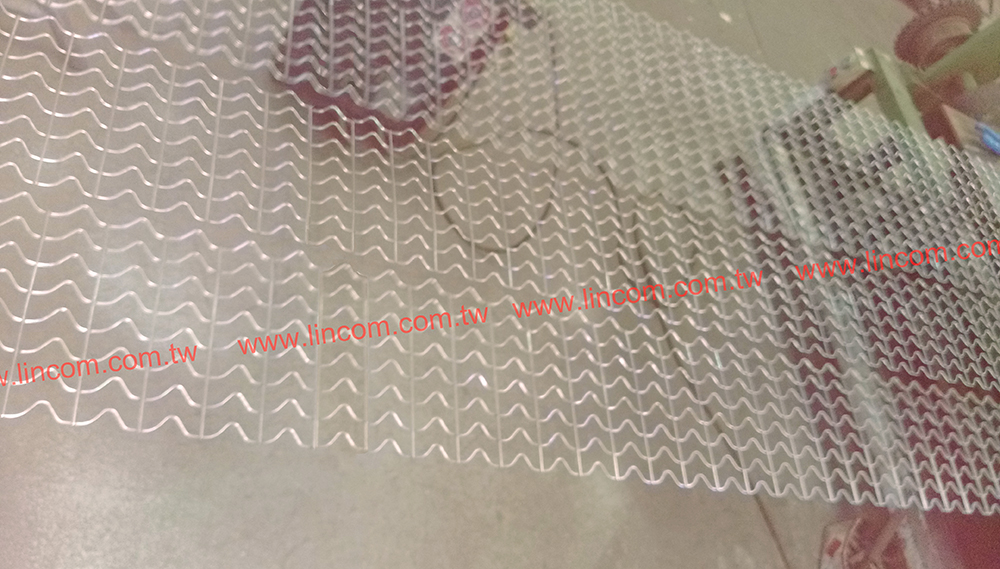

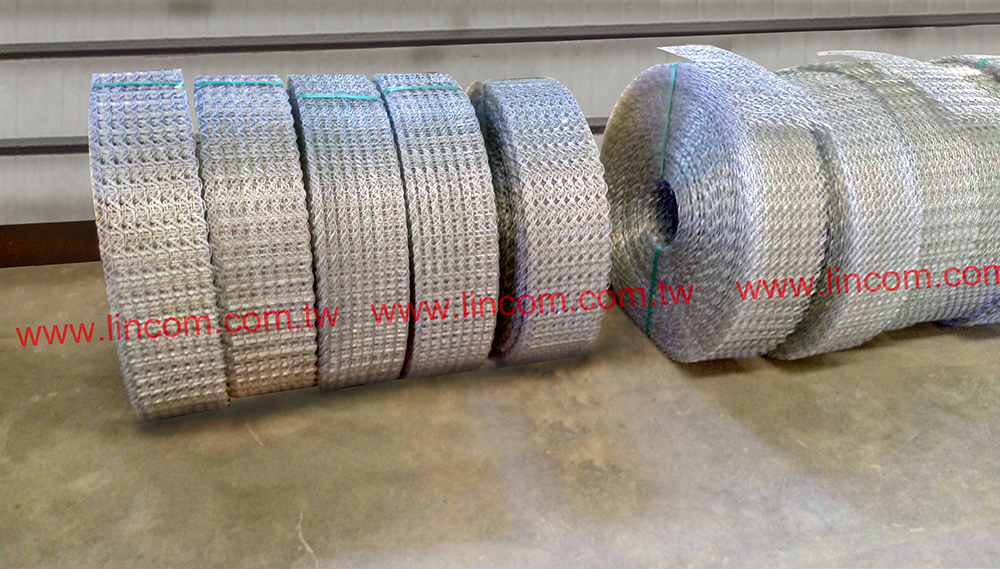

PNEUMATIC CRIMPED WIRE MESH WELDING MACHINE

* Mesh Width: 534 mm (after slitting to 3 mesh each 177.8 mm, 8 wires)

* Wire Diameter: Ø 1.4 - 3.0 mm

* Line Wire Number: 24 Line Wires

* Min. Line Wire Ptich: 25.4 mm

* Min. Cross Wire Ptich: 67mm

* Work Piece Length: 100 - 300 M/coil

* Work Piece Width: 177.8 x 3 pieces

Contents:Line Wire Payoff / Cross Wire Payoff / Line Wire Straightener / Cross Wire Automatic Feeding & Shearing Device / Welding Device / Servo Motor / Slitting Device / Forming Device / Recoiler Device.

※Customers specific requirement are Welcome!

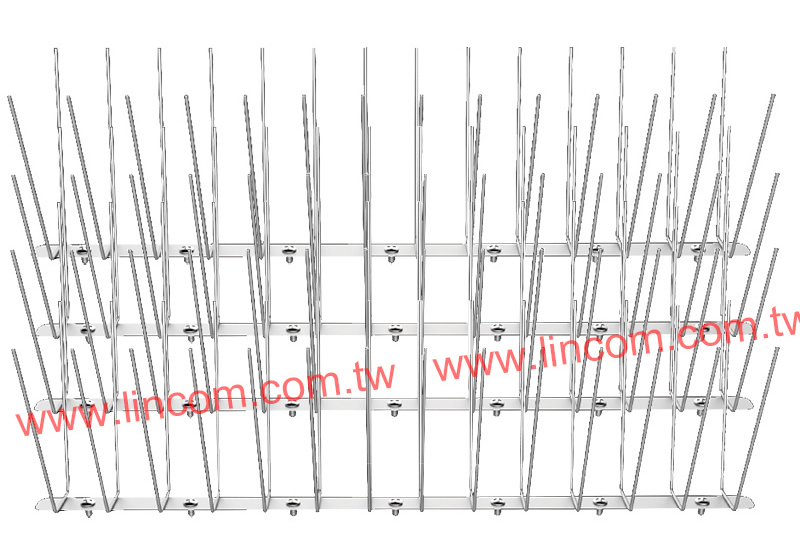

* Line Plate Material: Stainless Steel 304 2B, Mild Steel

Line Plate Width: 17 - 25 mm, Thickness: 0.7 - 0.8 mm

Hole Punching Diameter: 4 mm

* Cross Wires Material: Stainless Steel 304H

Diameter: 1.6 - 2.0 mm

Length: 220 - 320 mm

* Hole Spacing: 100/ 75/ 60 mm

* Cross Wire Spacing: 25/ 25.4/ 50.5 mm

* Spike Width: 55/ 155/ 203 mm (after bending)

* Equipped PLC with HMI touchscreen, all parameters and figures on screen. Working process and abnormal situation will be graphical presented.

* Fault diagnostic system with picture indication for fast removing. Line Wire feeding, pushing, and discharging all driven by inverter servo motor, while welding machine is controlled by S.C.R. and micro-computer controller.

※Customers specific requirement are Welcome!

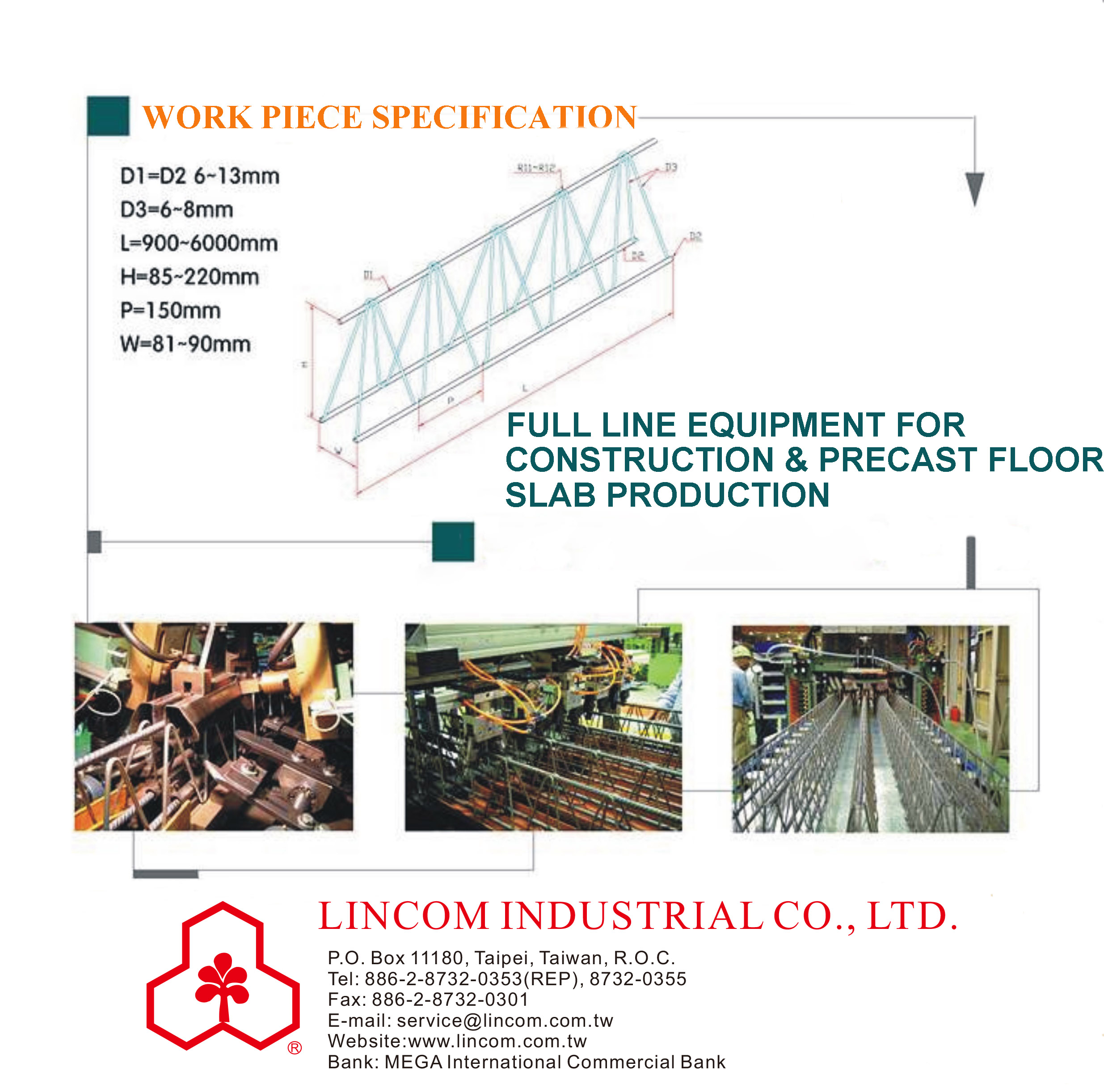

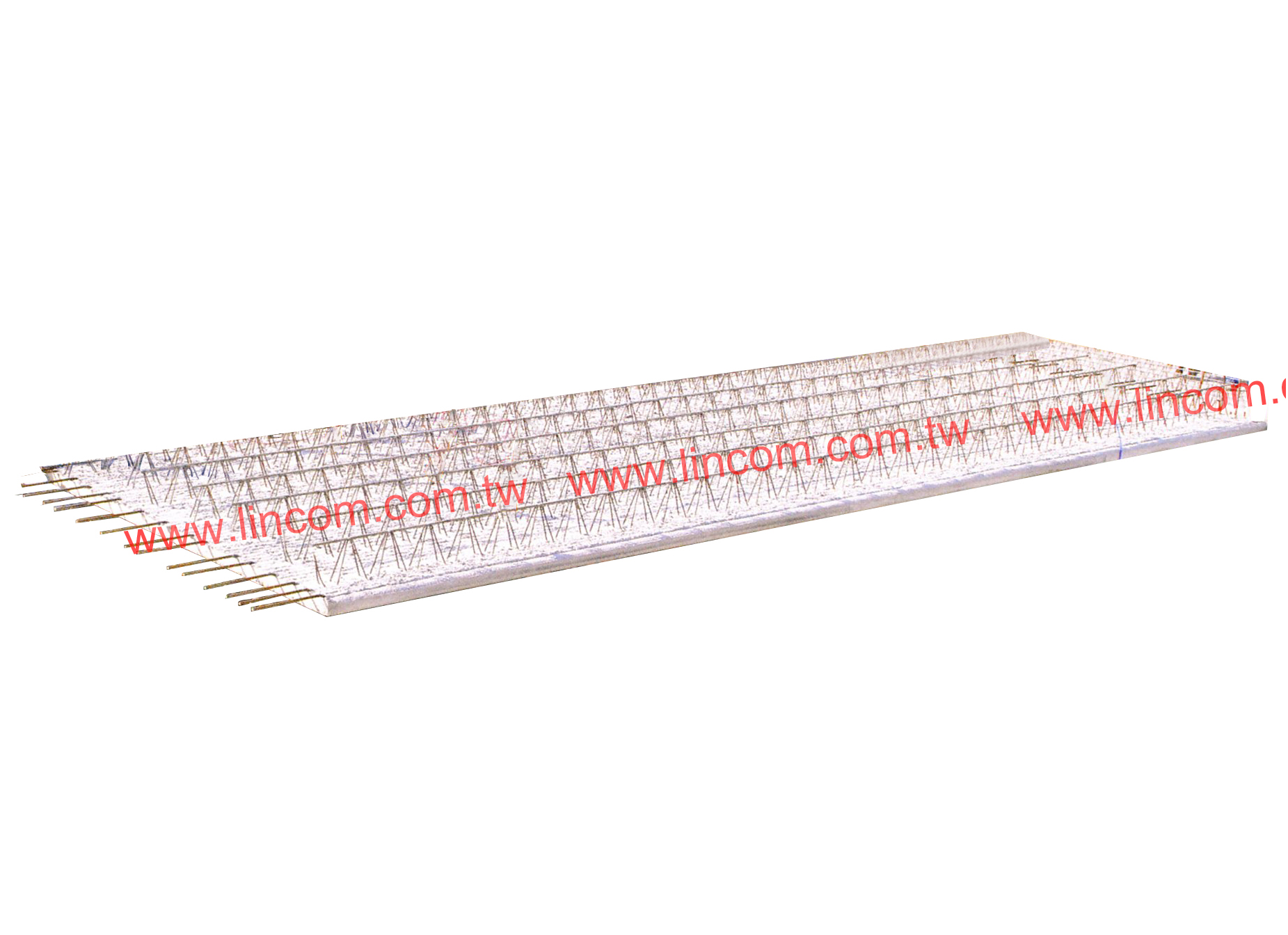

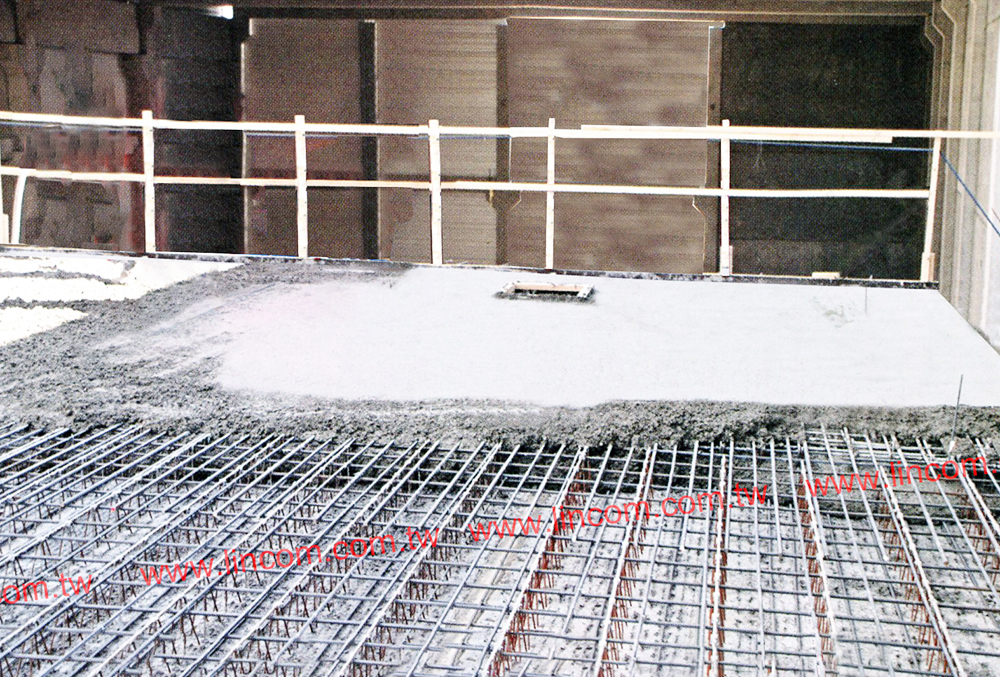

FULL LINE EQUIPMENT FOR CONSTRUCTION & PRECAST FLOOR SLAB content-01ION

AUTO LATTICE GIRDERS LINE

※Remark: For details please contact us.

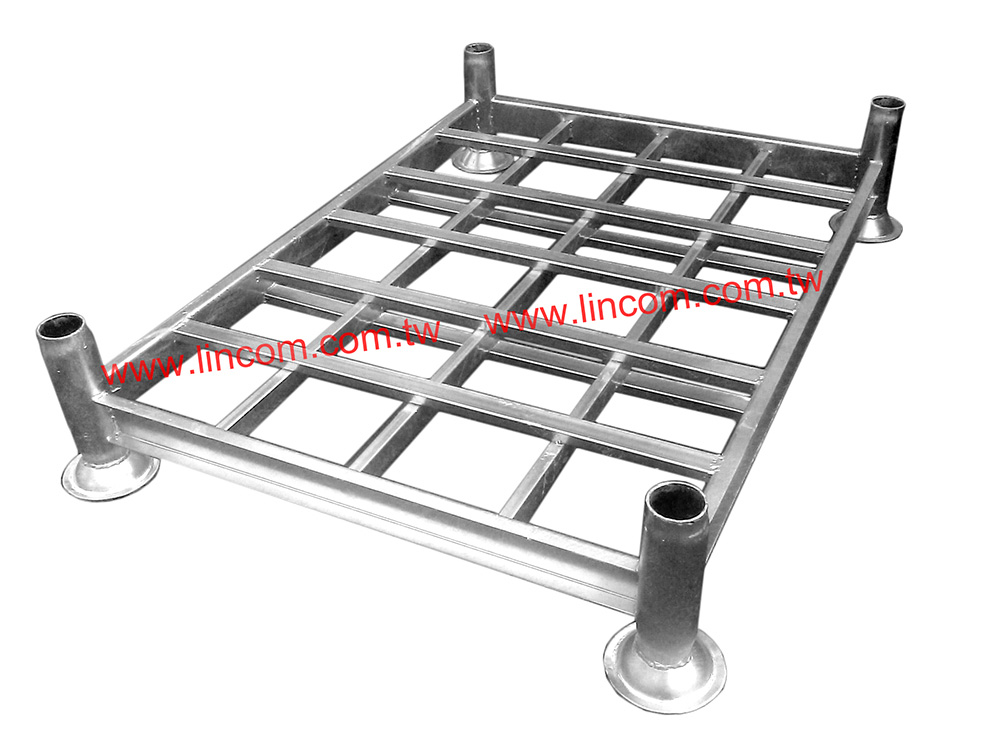

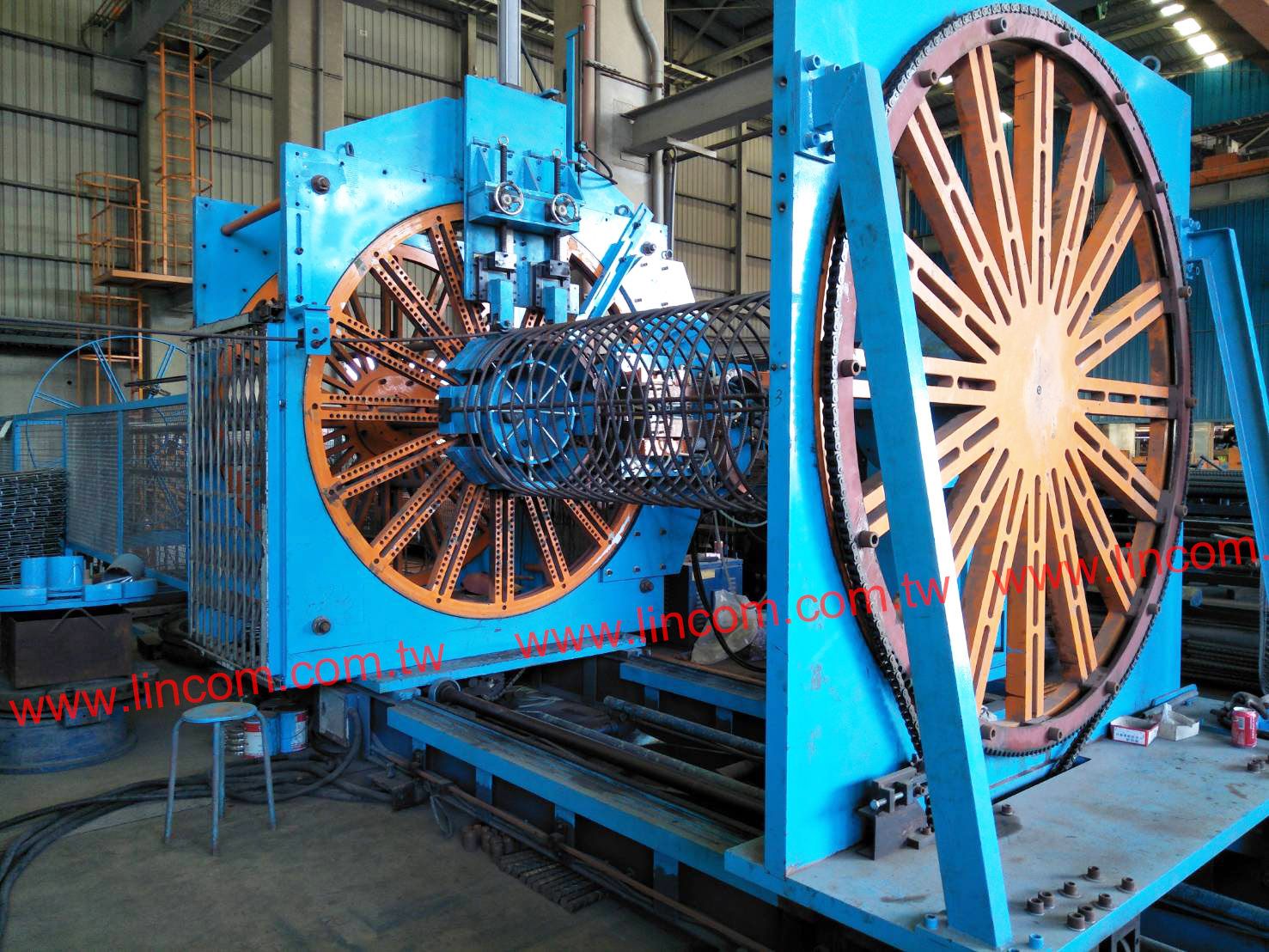

WIRE CAGE

We have equip our cage welding machine with heavy-duty welding unit and heavy frame & For overall costs down, we have also equipped with a repair-and maintenance-friendly design.

This machine is idea for Round Cage content-01ion mainly for bored piles, and also for columns and beams... The welding procedures stands for maximum welding point strength, even with large wire and bar diameters.

Model No. |

Cage Dia. Range |

Cage Length |

Wire Spiral φ |

Longitudinal Bar φ |

Spiral Pitch |

|---|---|---|---|---|---|

LCC-1200 |

200-1200mm |

As Request. |

6 - 16 mm |

10 - 32 mm |

50 - 500 mm |

LCC-1500 |

200-1500mm |

As Request |

6 - 16 mm |

10 - 32 mm |

50 - 500 mm |

LCC-2000 |

400-2000mm |

As Request |

6 - 16 mm |

10 - 32 mm |

50 - 500 mm |

LCC-3000 |

1000-3000mm |

As Request |

8 - 18 mm |

20 - 40 mm |

50 - 500 mm |

| ※Remarks: | 1.Right of modification reserved. 2.For details please contact us. |